Trains might be a reasonably cheap transport option - but rail infrastructure is very costly to build. Monorail, maglev systems and high speed rail are more expensive again - and prices really skyrocket when you have to build bridges, tunnels and winding mountain routes, or cover difficult terrain. Which is why Anatoly Unitsky's String Transport Systems look like they've got so much potential. The system uses solid steel/concrete rails, reinforced with extremely high tension steel wires, to provide an efficient and smooth rail system anywhere between 3 to 30 meters above the ground. It's earthquake, hurricane and terrorist-proof, and capable of supporting vehicle speeds over 500 kmh, too, making it a genuine high-speed rail alternative, for a fraction of the price of road or ground rail alternatives. Fascinating stuff!

The String Rail System

The UST uses steel or concrete rails, reinforced by hundreds of high-tension wires running through the middle of the rail, suspended above the ground on towers approximately 30 m apart. Unlike roads or rail systems, it can traverse mountains and other rough terrain in a straight line, and it's equally adept at crossing shallow waters, desert or forest, with minimal environmental impact at the ground level.

Optimal height for a UTS support tower would be around 5-6 m above ground - or 10-20 m where the underlying terrain is very rough. If money is no object, there's no reason why support towers couldn't be increased to as much as 100 m high or more.

Because it's a combination of solid steel/concrete and high-tension wires, it's not really appropriate to think of the UST as something like a chairlift. In fact, it's more accurate to look at a UST track more or less as a tiny pre-stressed concrete bridge, built for a fraction of the cost of a ground rail system or even a motorway.

A fraction the cost of rail

The above video outlines the rough process of building a UTS installation, and also shows a modified truck driving on an early demonstration installation in Russia.

A UST system is cheap to install for the simple fact that you can built it with a minimum of materials per km, and a minimum of ground preparation. You don't need to build expensive overpasses, tunnels or other infrastructure to make the UTS fit in around existing roads and other infrastructure - it's already up off the ground and out of the way.

Cost estimates are so low as to look downright suspicious - Unitsky quotes a figure of as low as US$50,000 per km for assembled string rail. Compare this to the cost of recent low-speed surface rail installations in Australia - from which the cost of a double-track rail service, not including land acquisition or station building, is very optimistically estimated at around AUD4.12 million (US$345 million) per km. The real cost of underground rail is in the realm of 10 times higher.

Unitsky estimates the final cost of a high-speed UST installation as being somewhere between three and 10 times less expensive per km than a railway, maglev system, monorail system or motorway. This is borne out in the estimated project cost of a potential installation between Abu Dhabi/Dubai/Sharjah - a 138km route estimated at US$280 million, or a little over US$2 million per km. It's unclear where this figure comes from, or whether it includes land acquisition, stations and other supporting infrastructure.

350-500kmh high speed string rail

The running surface it provides is exceptionally smooth - the tension of the steel wires within each rail ensures that there's a sag of only 1-5 cm between support posts so there's no perceivable 'bump' as a vehicle passes over them.

The smooth surface and negligible sag make the UST appropriate for high speed transit - Unitsky believes 350 kmh (~220 mph) should be immediately within reach, with 500 kmh (over 300 mph) possible after further development.

Aerodynamics are on the UST system's side as well - the biggest issue for ground vehicles at high speed is the pressure generated by air passing underneath, which causes the vehicle to lift off the ground. Formula one cars and other high-speed ground vehicles combat this by using spoliers and other design features to catch wind on the top of the vehicle and push it downward.

A UST system has no need for these kinds of aerodynamic inefficiencies - the vehicles can be shaped for minimum frontal drag with no consideration for downforce, as air underneath the vehicle can move as freely as air above it.

The aerodynamic drag coefficient of the Toyota Prius, a leader in passenger car aerodynamics, is around 0.26. A hummer H2, built with almost no drag consideration, has a drag coefficient of around 0.57. The German-designed Transrapid Maglev monorail connecting Shanghai to the Pudong International Airport has a top speed of 430 kmh and a drag coefficient of 0.26 - and a passenger vehicle designed for the string transport system has already been wind tunnel tested as having a drag coefficient of just 0.075. This is a big deal - as speeds increase, aerodynamic drag becomes far and away the biggest force a moving vehicle needs to overcome. The UST has a big advantage here.

Aerodynamic efficiency, coupled with the rolling efficiency of steel or alloy wheels on a solid concrete beam, lets the UST reach high speeds without requiring huge amounts of power. A simple 80 kW (107hp) engine is all you'd need to get a 20-person passenger vehicle up to 200-250 kmh. With a 200 kW engine, you could hit 400 kmh - a feat that the Bugatti Veyron needs over 700 kW to achieve.

A few string rail tidbits

There's so much information at the String Transport website that we could sit here writing about this system all week - so, while the high speed, high efficiency and low rollout cost of the UST system are probably the key features, here's a few other interesting tidbits:

- Anatoly Unitsky first started developing the UST system in 1977, and between him and a team that has at times included as many as 100 people, total development time stands at more than 500 man-years;

- A pilot installation in Khabarovsk, Eastern Russia, was planned for 2008, but canceled after specialists from the Moscow State University of Railway Engineering gave the project a negative review;

- For the most part, vehicles will travel more or less horizontally on the UST string rails. But if a load needs to be carried up a steep gradient, it's possible to use a different wheel configuration that increases friction and enables travel at up to 45-60 degrees of elevation;

- Unitsky claims the combination of rigidity and high tension makes the UST track structure extremely resistant to wind deflection - even hurricane-strength winds that can destroy power lines should have little effect on the UST structure. I'm not sure I'd want to be riding a string rail vehicle in a hurricane myself, though!

- Unitsky appears to be currently living in New South Wales, Australia, where his new company String Transport Systems is trying to get the UST system off the ground (pun intended) as a mineral haulage alternative in the Australian mining industry, where difficult terrain often inhibits mining operations;

- Due to the high tensions involved, it's not a simple operation for a UST track to go around a corner. Gentle curves are OK, but if you need to make a 90-degree turn, for example, you need to build a section of solid, non-tensioned rail for this purpose, and let the tensioned UST system lead in and out of the corner;

- If some catastrophic event, like an earthquake or a terrorist attack, was to destroy one of the support towers, passengers on the UST would hardly notice, according to Unitsky. The doubling of bridge span would result in an increased track deformation, but this would be taken up by the vehicle's suspension.

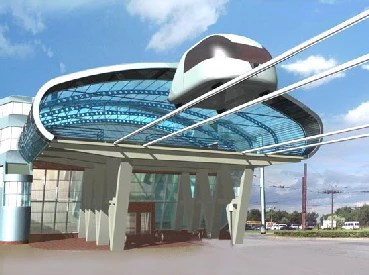

Here's another video - a CAD mockup showing how Unitsky envisions the UST operating as an urban and regional transport system. Let us know if you can translate the Russian for us!

The next video covers a range of the technologies Unitsky has patented in the 33 years he's been working on the system - including some pretty nifty vehicle designs and prototypes.

And finally, another video showing the rather sorry recent state of the original UST test installation from the first video. Situated in Ozery, around 100km outside Moscow, the test rig (built around 2001? ... the date is hard to pin down) now sits unattended, and as the videomaker points out, you can wander in and out and climb around on the facility as you please.

This video also offers a great close-up view of the UST technology, years after its original implementation. It looks a little rusted, warped in places and in a general state of disrepair. I wonder if that warping is any cause for concern!

Where to from here?

In all, the Unitsky String Transport System is a fascinating transportation alternative that seems to have notable advantages over rail, monorail, maglev and road transport.

Would I find it a bit freaky to be doing 350 kmh while hanging from a wire? Yes sir. Am I entirely convinced that the strings won't snap, even if a tower or three get taken out? No. Would a full scale demonstration convince me? Probably, yes. And this is the stage Unitsky is stuck at. His demonstration rig is small-scale, and there's nothing like the UST in operation anywhere in the world.

He's just finished a round of fundraising in Australia, and is currently planning to build a larger scale pilot/demonstration track. To be of satisfactory value as a demo rig, the track will have to be at least 2km long - which would then need to be extended to around 8km if high-speed testing was necessary. To get this far (stage 2 of the UST pilot implementation plan) will cost around US$15 million, and take 2.5-3 years.

We wish Unitsky all the best and hope to hear good results as the test rig and possible commercial installations come to light.

For more information, visit the American STU website.