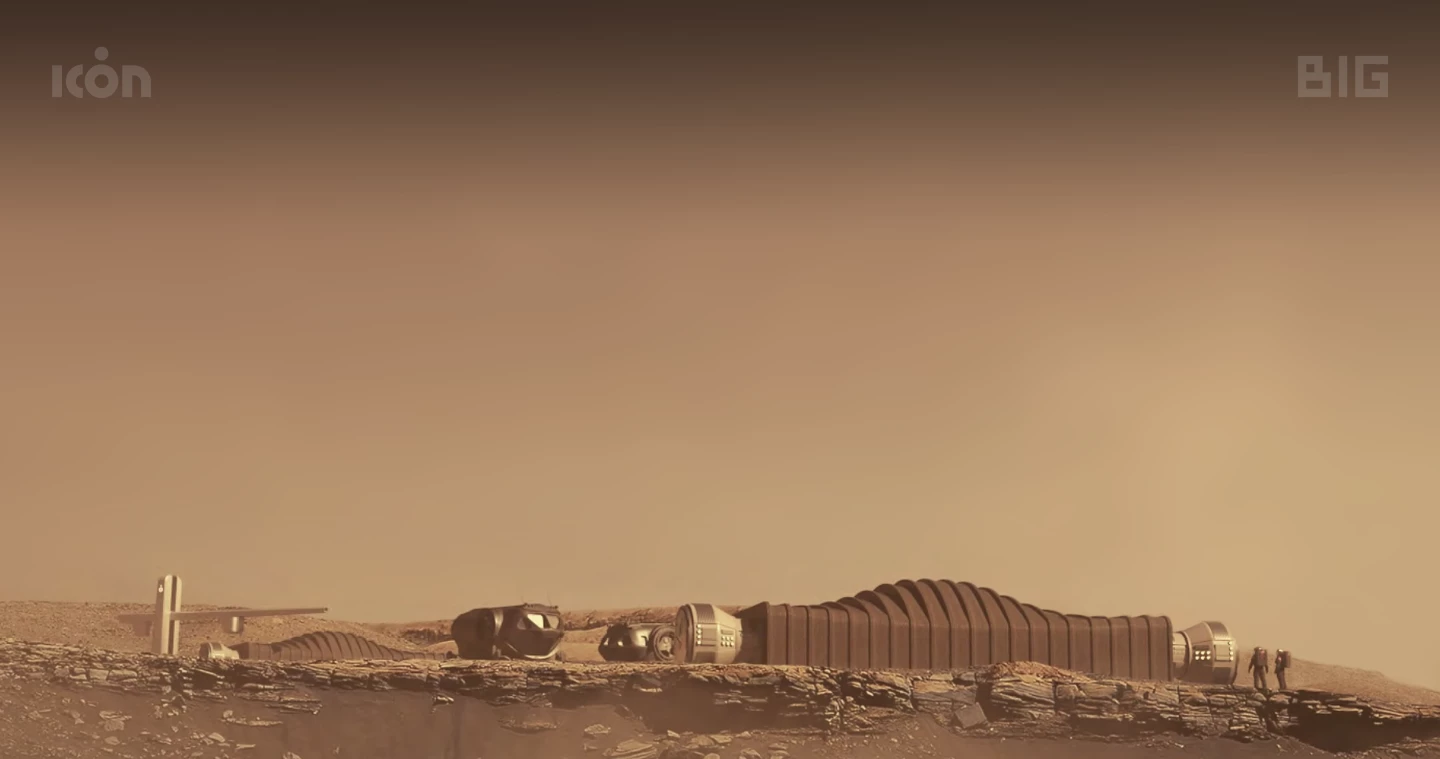

A mission to Mars seems more a case of when, not if, but where will astronauts actually live once they arrive on the Red Planet? To try and figure this out, NASA has commissioned high-profile architecture firm Bjarke Ingels Group (BIG) to design a 3D-printed simulated Mars habitat here on Earth, and is accepting applications from would-be participants willing to live in it for a year.

The project is named Mars Dune Alpha and is to be located in NASA's Johnson Space Center in Houston, Texas. It's part of the larger CHAPEA (Crew Health and Performance Exploration Analog) project that will consist of three year-long Mars surface mission simulations.

Starting in late-2022, Mars Dune Alpha will host four people and help put them to the test with challenges like limited resources, equipment failure, and communication delays. Simulated spacewalks, scientific research, and the use of robotic controls are also a possibility too. If you're reading this thinking "I could do that," (and are a US citizen or permanent resident), head over to NASA's application form to register interest.

If successful, you'd be living full-time in a shelter measuring just 1,700 sq ft (157 sq m) for 12 months. Its interior will be arranged on one level and it will also be flexible with movable furniture allowing its occupants to adapt it to their needs. It will include four crew quarters, a crop growing area, recreation area, kitchen, bathrooms, work area, a robotic room, and a treatment room.

"Four private crew quarters will be located on one end of the habitat; dedicated workstations, medical stations and food-growing stations are located on the opposite end, with shared living spaces found in between," explains Icon, which is 3D printing the habitat. "Varying ceiling heights vertically segmented by an arching shell structure accentuate the unique experience of each area to avoid spatial monotony and crew member fatigue. A mix of fixed and movable furniture will allow crew members to reorganize the habitat according to their daily needs, as will the customizable lighting, temperature, and sound control – helping regulate the daily routine, circadian rhythm, and overall well being of the crew."

Mars Dune Alpha is currently being constructed by Icon using the same Vulcan model 3D printer it used in previous projects, including the first 3D-printed homes to hit the market in the US. This extrudes a proprietary cement-like mixture named Lavacrete out of a robotically controlled nozzle in layers until the basic structure is built up. Human builders will then finish it off.

As well being commissioned to build this simulated Mars base, Icon has received funding from NASA for Project Olympus. In this project the 3D printing firm is working with BIG to imagine a space-based construction system to support future Moon exploration. BIG has also shown a prior interest in Mars-based architecture and plans a similar project in Dubai.

Source: Icon