Airbus says it's on track to have a fully operational megawatt-class electric powertrain, fueled by cryogenic liquid hydrogen, tested in flight by 2026, ahead of a full-scale zero-emissions passenger airliner it plans to put into service by 2035.

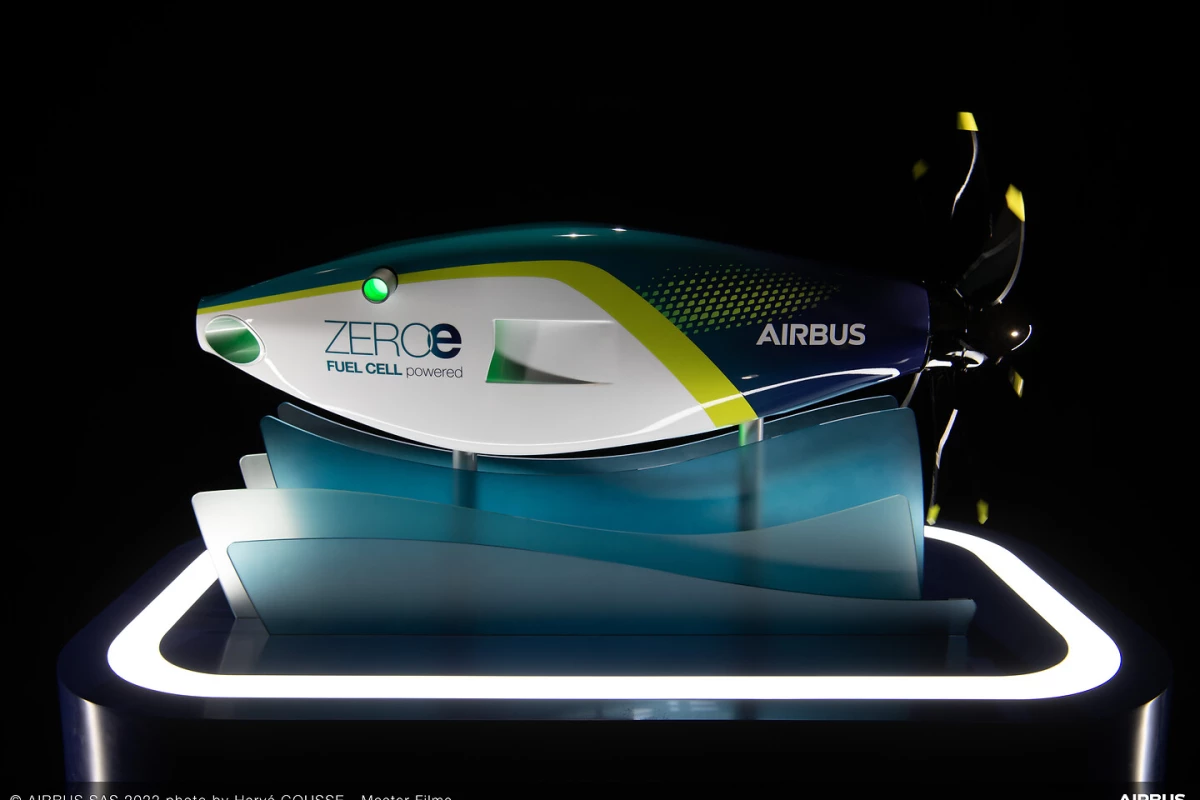

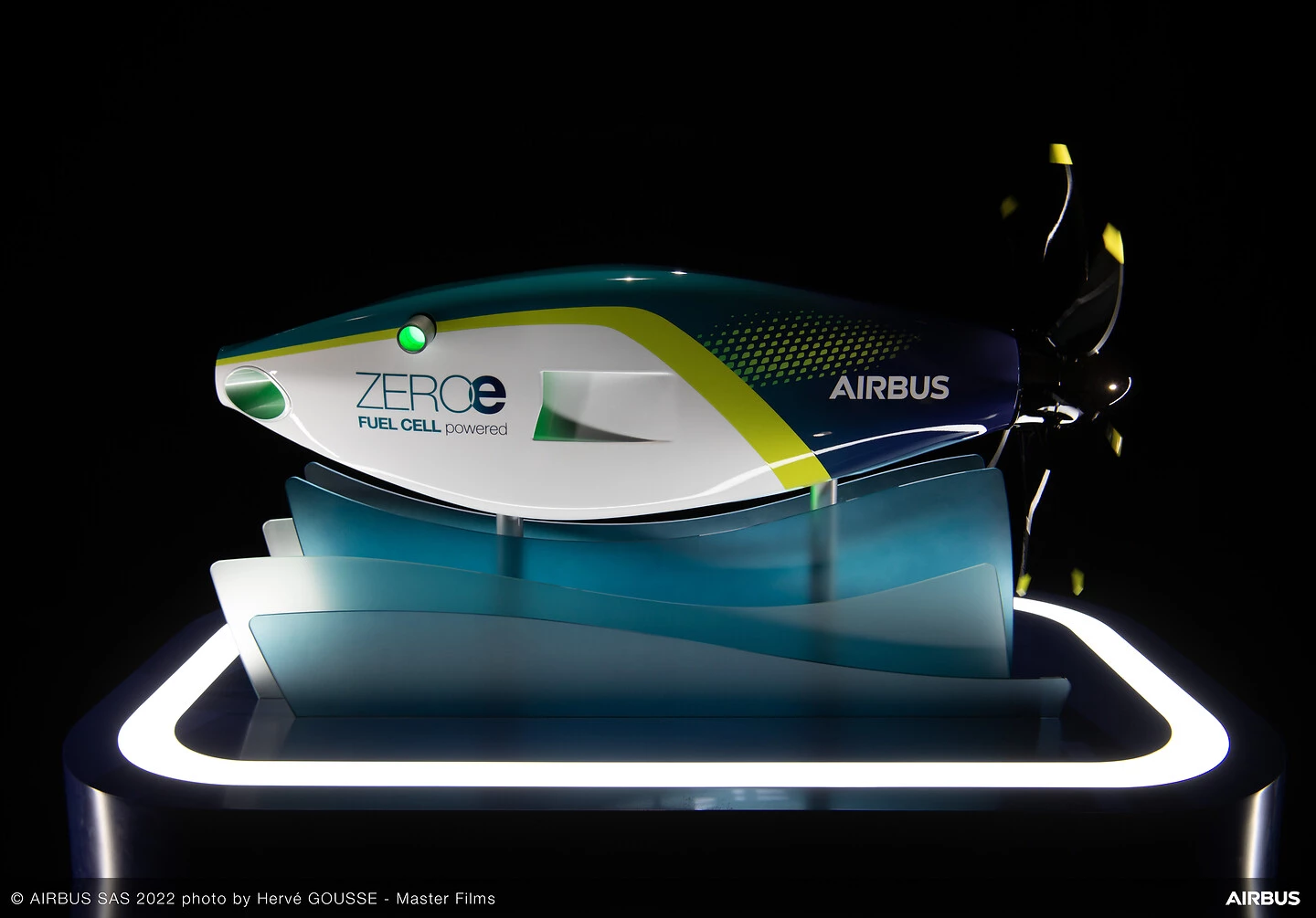

These cutting-edge powertrains, as we discussed back in 2020, are eventually slated to be entirely encapsulated in large pods, slung under the wings where you'd normally find a beefy jet turbine. Each pod will have its own liquid hydrogen tank inside, as well as cryogenic cooling equipment to keep the fuel under its extremely cold boiling point of -253 °C (-424 °F, or just 20-odd Kelvin). Each pod will also have its own fuel-cell stack, to convert gaseous hydrogen into electricity, and an electric motor to drive a propeller or electric jet.

By running the entire fuel system and powertrain out in these pods, Airbus says it can free up more space in the fuselage for cargo and passengers. And it plans to make them detachable, such that aircraft can easily be kept in the air simply by swapping out whole pods for maintenance and the like.

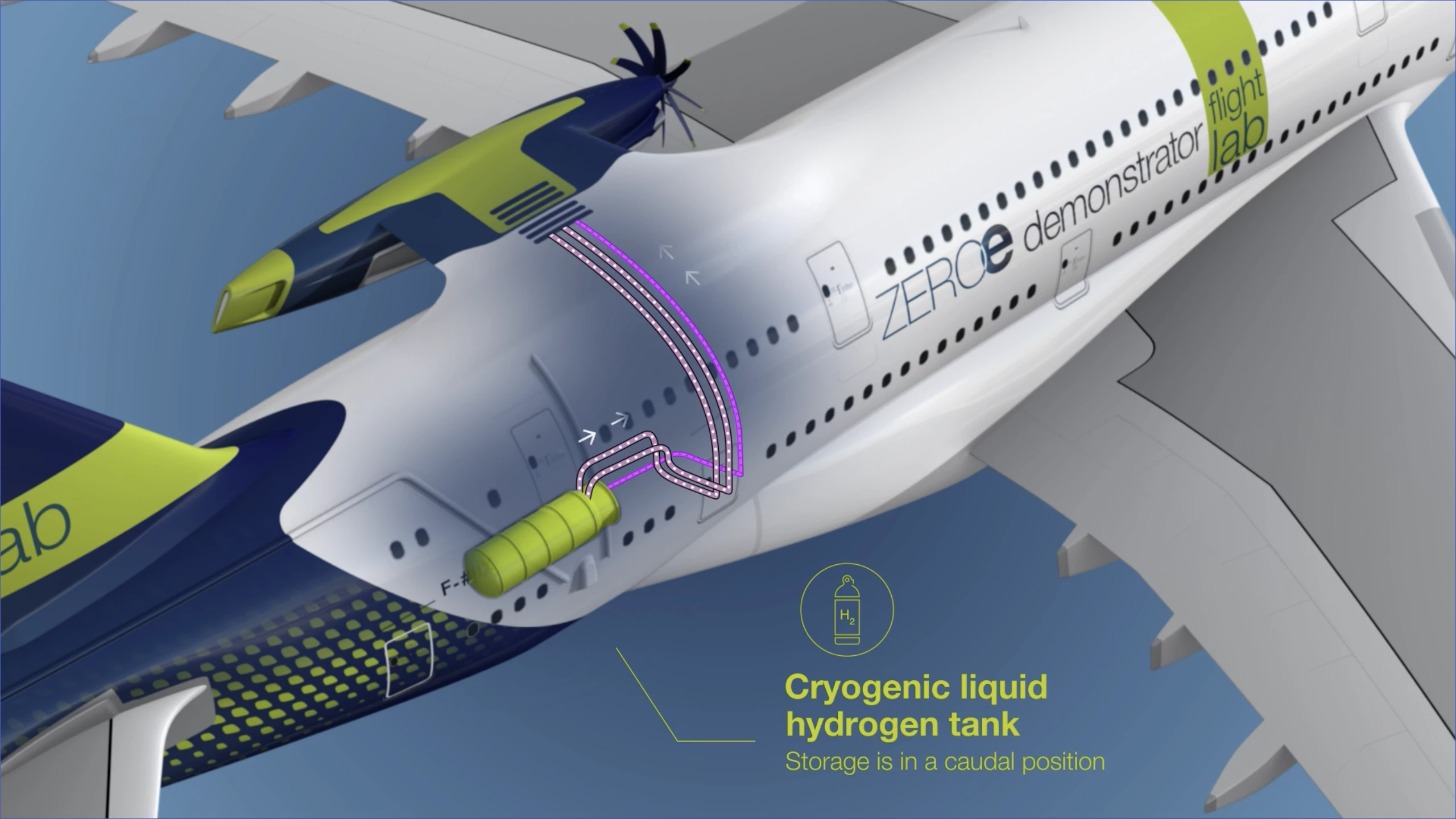

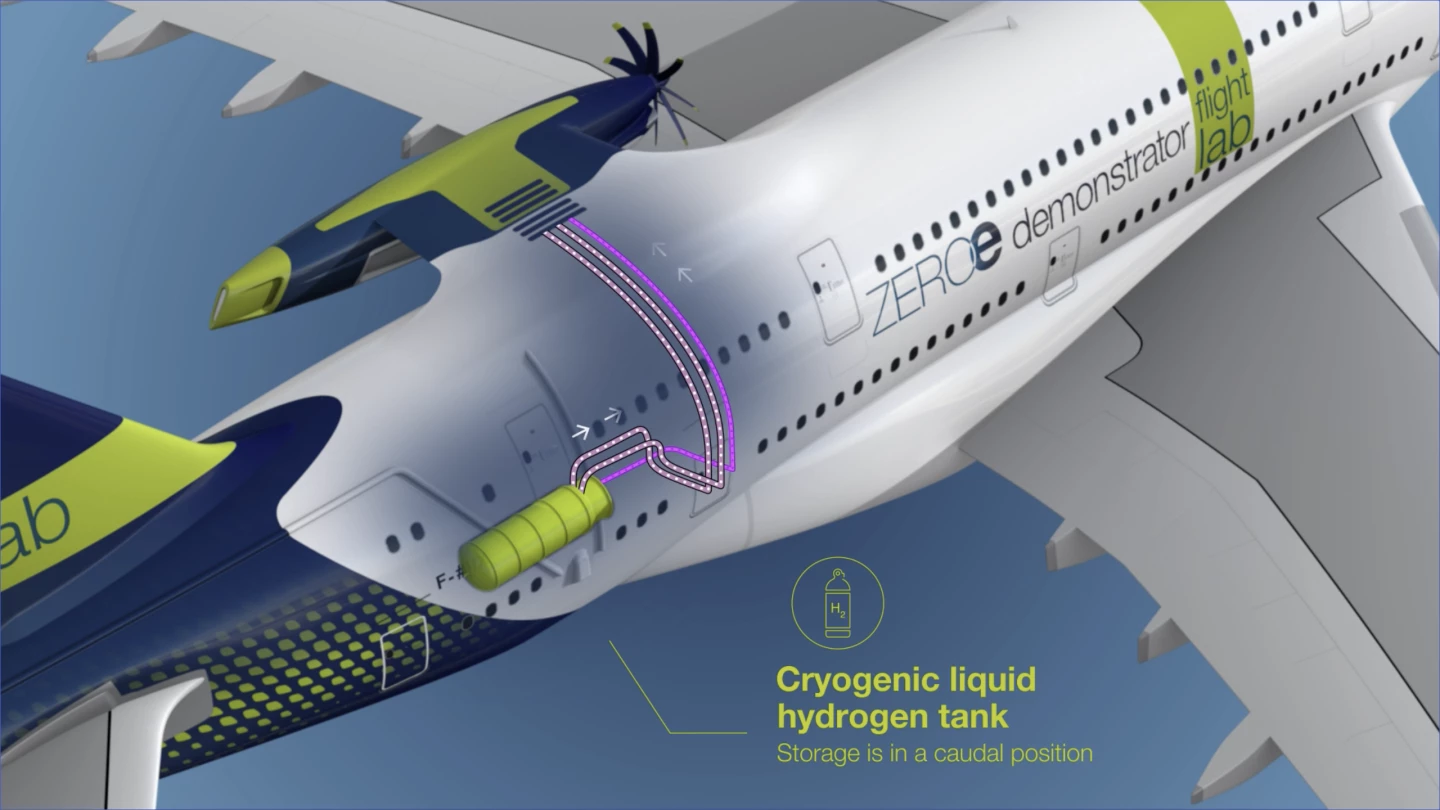

Airbus is now working on a prototype of this kind of powertrain – albeit one that's slightly less integrated, with the liquid hydrogen system located inside an unpressurized section in the fuselage of the aircraft. The aircraft in question will be a full-size A380 airliner, specially set aside for zero-emissions concept testing at service altitudes. It'll run a standard jet-engine powertrain, with the hydrogen-powered propeller and pod hanging off one side of the top of the fuselage, in front of the tail.

"In terms of aerodynamics, the A380 is a very stable aircraft," says Mathias Andriamisaina, Head of ZEROe Demonstrators and Tests at Airbus. "So the pod attached to the rear fuselage via the stub doesn’t pose much of an issue. Furthermore, the airflows from the pod and its propeller do not affect the airflow over A380’s tail surfaces."

Keeping the cryogenic fuel system in an unpressurized environment makes this a better test with respect to the final designs that'll keep their fuel out in the pods – but it also keeps the hydrogen fuel separate from the cabin, and allows the team to vent hydrogen gas straight out into the ambient air through emergency venting lines if necessary.

The end goal, of course, is to create a zero-emissions airliner capable of carrying enough energy to fly the same routes these giant birds currently do running Jet-A kerosene fuel. Batteries are simply way too heavy and bulky to carry enough energy for long-haul flights, and gaseous hydrogen systems, while offering considerably greater range than batteries, still fall short of jet fuel. Liquid hydrogen, on the other hand, can carry enough energy to do the job, opening up a genuine path towards zero-carbon aviation.

It's cutting-edge technology though, adapted from space programs, and it needs to be very thoroughly tested before it makes its way into widespread use. So it's good to see a company with the kind of resources Airbus can marshal pushing liquid hydrogen forward with a view to deploying it at scale.

Airbus intends to have a zero-emissions airliner up and running and in service by 2035. The company says this liquid hydrogen system could be a part of that aircraft, and it expects to have the test-equipped A380 flying by 2026 to begin proving the cryogenic powertrain. Meanwhile, it has partnered with ArianeGroup to design and build the world's first liquid hydrogen refueling facility for zero-emissions aircraft, which it plans to have operational at Toulouse, Blagnac airport by 2025.

Source: Airbus