The entire airline industry needs to wean itself off jet fuel over the next few decades – but it's still buying enormously expensive jet aircraft that are expected to keep bringing home the bacon for more than 20 years. Australian company Aviation H2 hopes to clean up commercial flight by converting existing aircraft to burn green ammonia instead of standard Jet-A jet fuel. To do so, it's planning to have a nine-seat passenger jet in the air and flying on ammonia by the middle of next year.

Ammonia, as we've discussed at length, is a promising energy carrier and future fuel with interesting potential for decarbonizing sectors like shipping and rail. The second-most produced chemical in the world today, it's primarily used as a fertilizer, but as the clean energy revolution kicks in, it'll start to be used effectively as an easier way to move and store green hydrogen.

Renewable energy, as we all know, isn't produced where and when you want it. Often, clean energy potential sits an inconvenient distance from where the demand is. If that clean energy is used to electrolyze water and produce hydrogen, it can be stored and transported. But that hydrogen can also be mixed with atmospheric nitrogen to produce ammonia, which travels much better than either gaseous or cryogenic liquid H2.

"Hydrogen gas is very light for the energy it holds and liquid hydrogen is a more compact form," Aviation H2 Director Christof Mayer tells us over a video chat. "But the tanks are big and heavy. We certainly don't discount liquid hydrogen or any other form of hydrogen as an option. We're not shutting those down. We're just going with ammonia for now. It's the simplest conversion, and that intrinsically will make it the most reliable, and that in itself makes it intrinsically the safest."

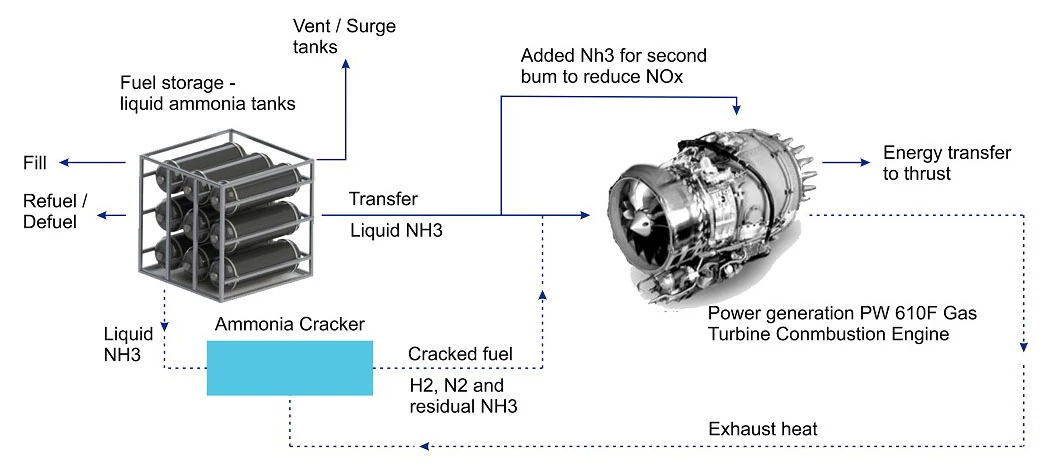

There are a few different ways to get the energy out of ammonia as electricity, but Aviation H2 has zeroed in on its potential as a combustion fuel. With a few modifications, a regular jet engine can be converted to run on ammonia, eliminating all its carbon dioxide emissions in a way that doesn't throw the baby out with the bathwater. The operation will be much faster and cheaper than a hydrogen fuel cell conversion, which would require you to throw out your perfectly good turbofan engines and replace them with electric motors, as well as gutting your fuel storage systems and putting in something radically different.

"We need to modify the fuel storage system into something that's basically similar to an LPG tank," says Mayer. "So it's the fuel storage, the engine control, and the engine, those are the big ticket items that we need to develop. But we're not really changing the design of the engine much at all physically."

Safety, of course, will be under extreme scrutiny throughout the clean aviation revolution, and to that end, Aviation H2 and other companies like it will eventually have to have all their powertrains certified by relevant aviation authorities. Emissions will also be under the microscope, and here, ammonia combustion runs into a problem. As the hydrogen in ammonia is broken off and joined with atmospheric oxygen to form water, a percentage of the nitrogen also gets oxidized in the flame, causing environmentally harmful nitrous oxides.

Mayer says the company is working on solutions. "Yes, it gives off nitrous oxides," he tells us. "But we can control those by special processes. We don't just squirt the ammonia in there and burn, there's certain things we have to do to it, and there's certain controls we have to put in place inside the fuel control system."

The company's initial target is to get a small regional nine-seat jet built and flight tested. After three months of feasibility studies, it's signed an agreement with charter operator FalconAir, giving Aviation H2 access to FalconAir's hangars, facilities and operating licenses. FalconAir will help acquire turbofan engines for ground-based testing, as well as the aircraft itself, most likely a Dassault Falcon 50 business jet, since it's got three engines, but can run on two.

As far as range goes, the initial plan is to build an aircraft capable of hour-long flights, with the same engine thrust and performance characteristics as it would get on Jet-A. It'll be a useful range to begin with, says Mayer, better than other zero-carbon options, and with some further development the company believes it can get ammonia-fueled flight into the ballpark of traditional fuel ranges as they stand today.

The plan is to have a plane in the air, with at least one engine running on ammonia, by mid-2023, to prove the concept – this could be a first for jet-powered aviation, although in broader terms NASA's X-15 flew on rockets powered by ammonia and liquid oxygen back in 1959. The company will then go public on a stock exchange to raise the funds needed to get an ammonia powertrain patented, certified and commercialized as a product. Eventually, Aviation H2 hopes to begin retrofitting existing planes as a transitional step for carriers looking to decarbonize, taking advantage of the fact that the rest of the aircraft is already fully certified to bring down compliance costs.

"There's a lot of small jets in the world, particularly in China, America and Europe, that you don't want to throw on the scrap heap," says Mayer. "They're major investments for their operators. And these turbofan engines need to be rebuilt every so many thousand hours. So retrofitting makes sense."

Long-term, the company envisions a drop-in hangar service where companies can leave their planes for a matter of weeks, then pick them up and have them running carbon-free.

"The bottom line is, this really needs to happen," says Mayer. "It's got to happen. Now's the time for pioneering development companies like ours to move fast. Down the track, we expect larger companies to work off the back of some of the things we've done. But it's got to be done, and that's part of the reason why there's so much interest in it. "

Aviation H2 is not the only company working on ammonia-based aviation. Notably, the UK's Reaction Engines, the company behind the SABRE rocket engine, is working on a similar project. These guys appear to already have bench testing underway for their engine precoolers, and are working with hypersonic speeds in mind. Also, the University of Central Florida has embarked on a five-year ammonia aviation project in collaboration with Boeing, General Electric and other partners, funded by NASA to the tune of US$10 million.

Definitely an area to keep an eye on. Check out a video below.

Source: Aviation H2