A hybrid-electric jet engine may seem as absurd as a horse-drawn Zeppelin, but GE Aerospace is ground testing a new megawatt-class hybrid turbofan engine and its full powertrain that is powerful enough to run a medium-haul narrow-body airliner.

Aerospace engineers have been putting a lot of effort into developing electric propulsion systems for aircraft but even after over half a century of work they keep hitting a wall. Electric motors, for all their advantages, depend on an outside power source to function. And that's where things go pear shaped.

If an aircraft propelled by electric motors is powered by, for example, batteries, that's a real problem. Batteries have an energy density that is 1/50th of aviation fuel, so it takes 50 pounds of batteries to do the work of one pound of aviation fuel. Worse, as aviation fuel is burned up, the aircraft gets lighter. A battery-powered aircraft remains the same weight from takeoff to landing, which is not good.

What this boils down to is that heavier-than-air, passenger-carrying electric aircraft can only go in one of two directions. Either they have to be ultra-light soaring planes that rely on solar panels to act as what are essentially powered gliders, or they have to be content with very short ranges and very small payloads.

So why is GE able to build a hybrid-electric jet engine big enough to be installed in a Boeing 737? The answer is that the electric component of the powertrain is meant to supplement the turbofan jet, not supplant it.

Developed as part of NASA’s Electrified Powertrain Flight Demonstration (EPFD) project and the Hybrid Thermally Efficient Core (HyTEC) program, the new design incorporates components that act as both motors and generators in the core of the jet engine. These are coupled to the engine shaft and can be used to both turn the turbofan or charge batteries and power onboard electrical systems. This arrangement eliminates the need for an auxiliary engine or bleeding air to generate electricity.

According to the company, it operates in a number of different modes. The generation mode is used when in low-demand flight phases like descent or taxiing. During this, the electric motor/generators (EMGs) generate high-voltage DC electricity to recharge onboard batteries and run subsystems. Meanwhile, the motor mode kicks in during takeoff and climbing. This is when the EMGs use stored power to help turn the engine shaft to boost fan and compressor rotation without using additional fuel.

Because the system operates on a megawatt scale the silicon carbide power inverters generate a lot of heat, so a dedicated cooling system is needed to transfer the heat from the electrics to the fuel, which acts like a heat sink.

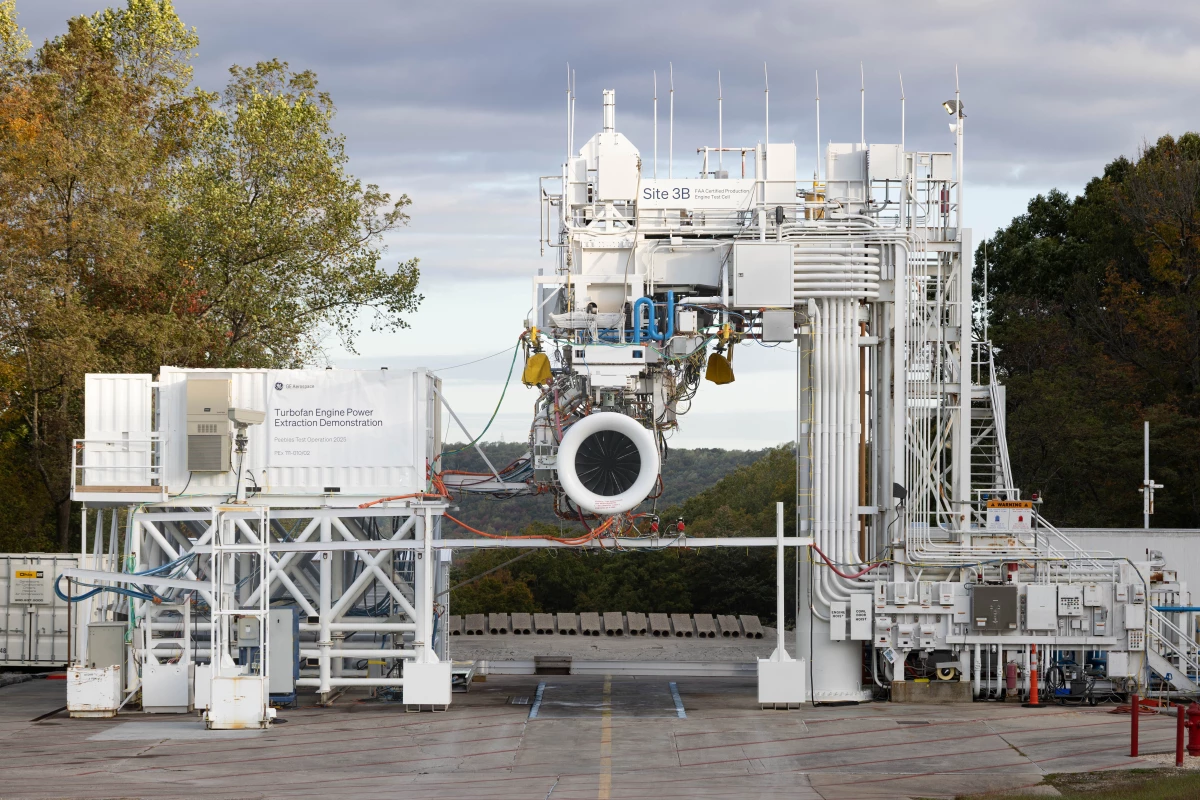

In the latest ground tests using a modified GE Passport turbofan engine, the system was put through various different modes during which GE says it demonstrated narrow-body hybrid operation, including without intermediate batteries. In addition, it was put through what is called a replicated flight environment to make sure the electrical systems could handle the thermal and vibrational stresses it would meet when in service.

"Hybrid electric propulsion is central to how GE Aerospace is redefining the future of flight," said Arjan Hegeman, vice president of future of flight for GE Aerospace. "Our latest milestone successfully demonstrated a narrow-body hybrid electric engine architecture that doesn’t require energy storage to operate. It’s a critical step to making hybrid electric flight a reality for commercial aviation with technologies that meet customer needs for greater efficiency, durability, and range."

Source: GE Aerospace