Last time we looked in on aerospace motor startup H3X, it was still in the perinatal stages, with little more than renderings and big plans to create the most power-dense motors known to man. Since then, it's gotten its first round of motors out to customers and signed contracts with major players like the US Air Force and NASA. Hot off an eight-figure funding round, it's now working to launch bigger, badder megawatt-class machines to take a bite out of carbon emissions in the aerospace, marine and industrial sectors.

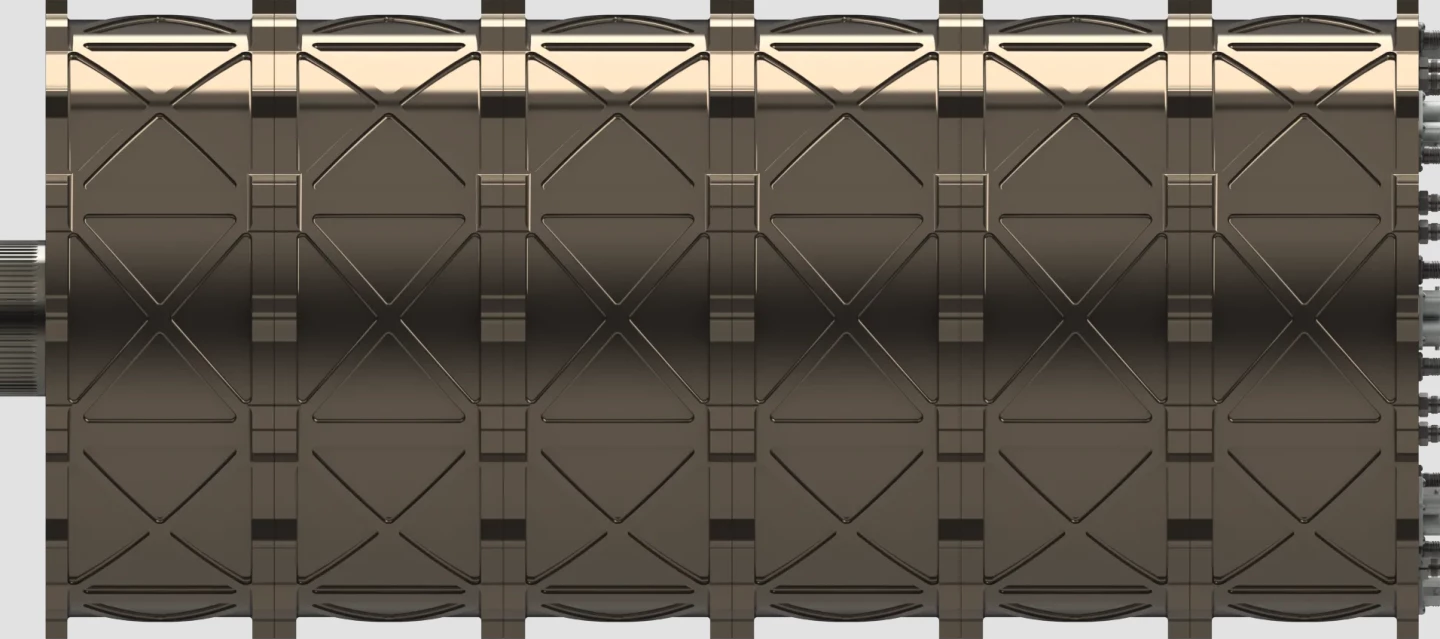

More power typically brings on more weight by way of larger or more numerous motors and drive components. It's a simple, intuitive rule that's hard to break, but H3X seems to have one highly effective formula down. Its comprehensive strategy to cut weight, optimize efficiency and boost power includes using a single additive-manufactured cooling jacket to cool both the motor stator and the power electronics, improving its stator winding design and optimizing its electromagnetics.

Long story short, H3X manages to stuff its compact integrated motors with serious power-to-weight. Its current motor lineup consists of three models topping out at the 200-kW HPDM-250. The 18.7-kg (41.2-lb) motor weighs a little more than the projected 15-kg (33-lb) 250 unit from back in 2020, owing largely to its integrated 6.7:1 gearbox, but still pulls off an impressive power density of 10.7 kW/kg. It also manages a better-than-originally-projected peak system efficiency of 95.4%.

For comparison, the HPM-400 motor UK manufacturer Equipmake introduced in 2023 as the unit it "believed to be" the most power-dense in the world has a density of 13.3 kW/kg. But Equipmake calculates its figure using peak power, not continuous power. If we're comparing oranges to oranges, H3X's HPDM-250 edges it out with a 13.4 kW/kg peak-power density. Furthering the HPDM's impressive numbers is the fact that H3X integrates the inverter within its 18.7-kg motor package, whereas Equipmake's inverter is a separate 10-kg (22-lb) component.

Simply put, the HPDM is an absolutely world-class power-dense machine, and the family is now growing bigger and significantly more powerful. H3X announced on Tuesday that it had closed a US$20 million oversubscribed Series A funding round and plans to use the money for developing the next three motors in its lineup: the HPDM-350, 1500 and 2300, pushing its tech into the megawatt class.

"We're on an ambitious journey to become the world's leading supplier of advanced electric motors," said Jason Sylvestre, H3X cofounder and CEO. "With remarkable speed, we've proven that this technology works and has a key role to play in enabling sustainable aviation, decarbonizing the marine and industrial sectors, and unlocking next-generation electrified defense technology."

H3X has released projected specs for the HPDM-1500, estimating it will weigh in at 125 kg (276 lb). The motor will develop 1,500 kilowatts of continuous power, meaning its power density is slated to surpass the HPDM-250's, achieving 12-kW/kg (continuous).

That figure is quite notable because it equals the target benchmark that the US government's Advanced Research Projects Agency-Energy (ARPA-E) set through its ASCEND program to help in development of net-zero single-aisle electric passenger aircraft sized comparably to a Boeing 737. The agency has determined that a power density of 12-kW/kg continuous or more is required for such an aircraft to complete a typical five-hour flight.

Current aircraft propulsion systems operate in the 3- to 4-kW/kg range, estimates H3X, which also projects that in some aircraft, range could be effectively doubled when swapping out existing propulsion systems for its power-dense units. As part of this calculation, the weight saved by using HPDM motors would be allocated to added battery capacity.

In addition to electric airplanes and eVTOLs, H3X is developing its higher-power next-gen motors for applications that include large marine vessels like ferries, tugboats and submarines, industrial equipment, and electric locomotives. The HPDM line is also positioned for use in hybrid systems, both as motors and as generators. With hollow shafts, the HPDM units are designed for modular stacking, and H3X says that up to six 1500 motors could be stacked for a total of 9 megawatts of power.

H3X designs, tests and manufactures its motors at its 17,000-sq-ft headquarters just outside of Denver. In addition to developing its next round of motors, the company will allot some of the $20 million Series A funding toward scaling up production and fulfilling existing contracts.

Source: H3X