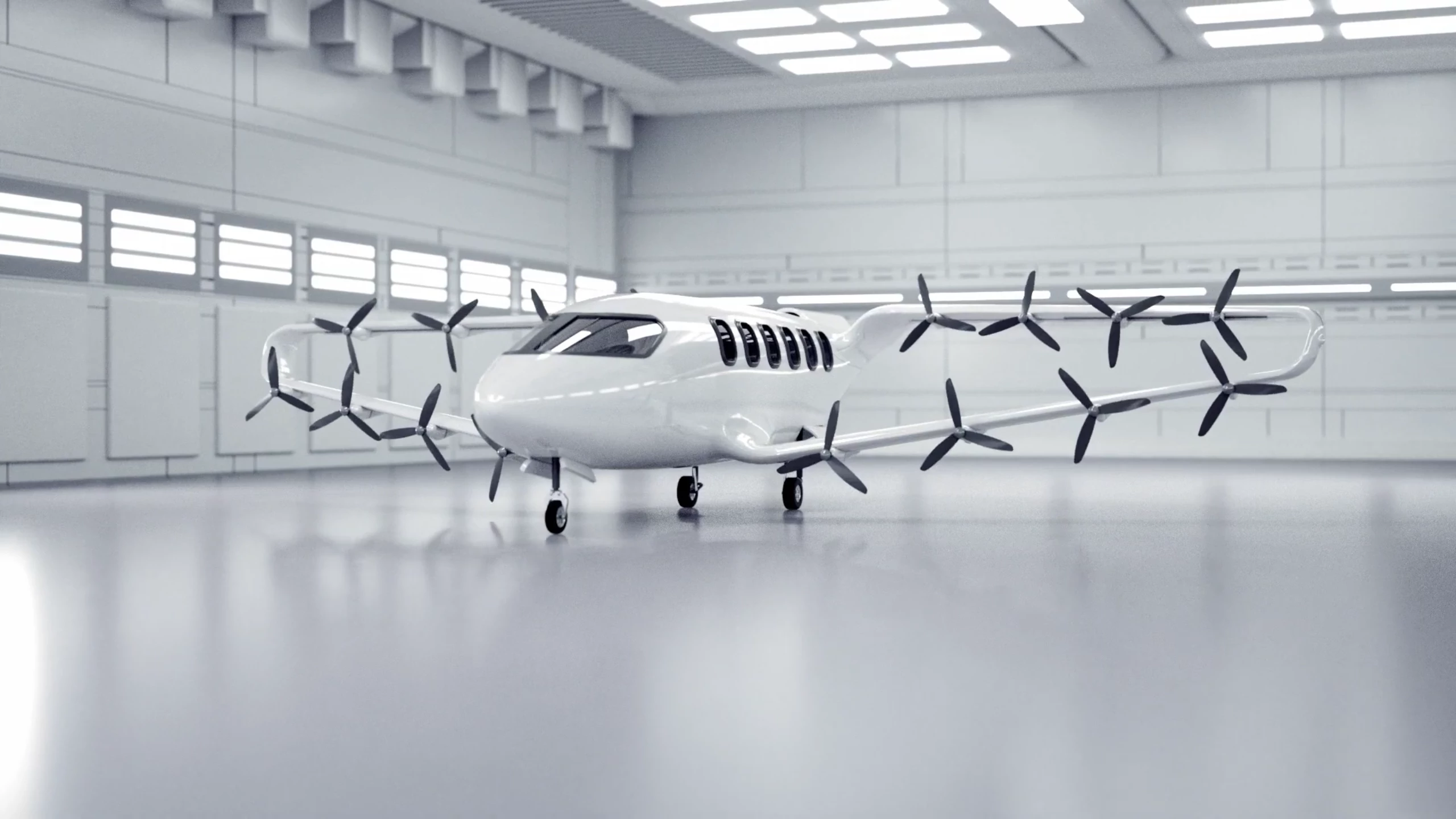

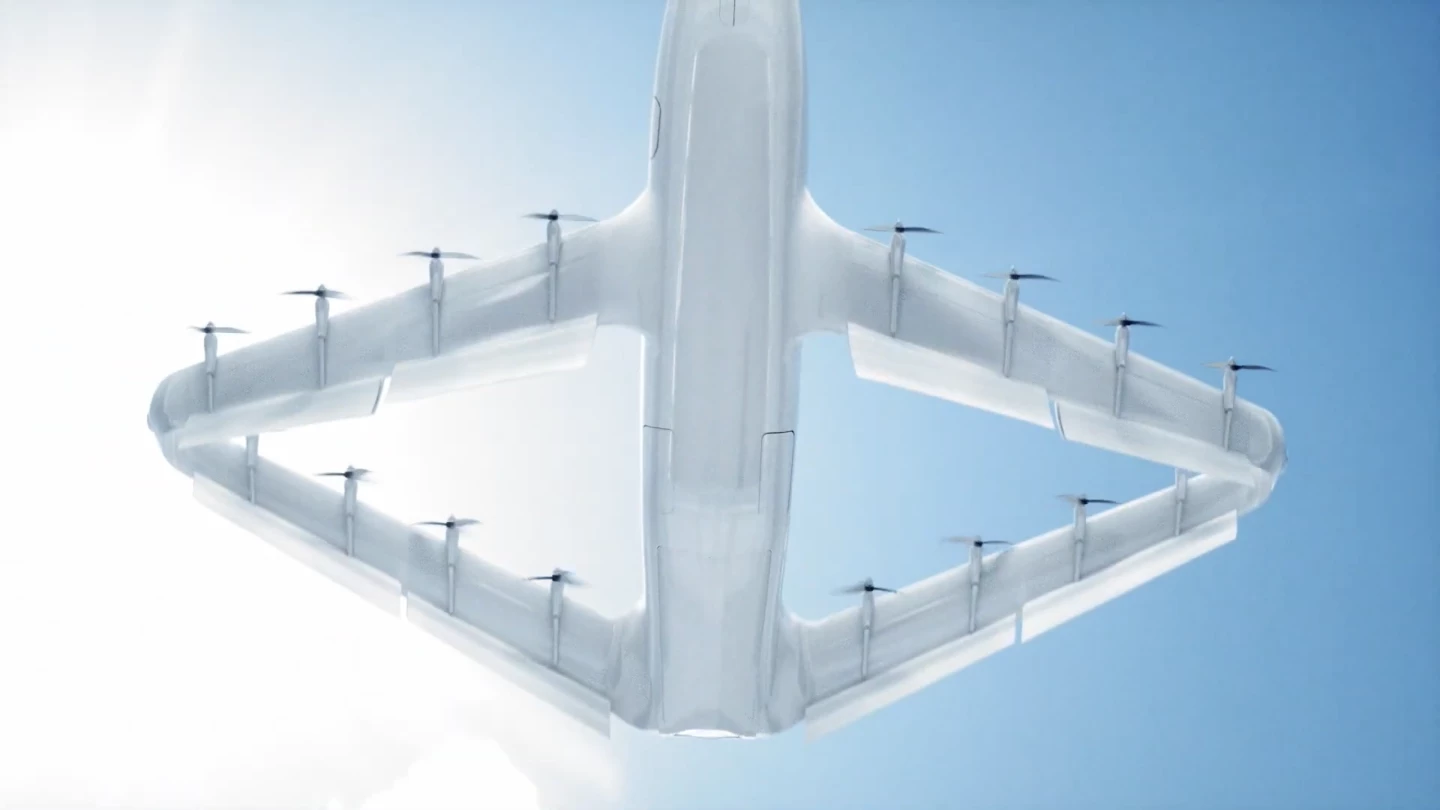

When we first covered Odys Aviation (formerly Craft Aerospace) last September, we were struck not only by the impressive figures attached to it, but by its completely unique design. Where the vast majority of eVTOL designs are two-to-five-seaters aimed at the urban air taxi space, Odys put forth a nine-seat hybrid concept targeted at replacing fossil-burners on longer-range regional air routes, flying helipad to helipad to vastly cut down on total trip time by removing airports from the equation wherever possible.

The range-extended hybrid system promises up to 200 miles (322 km) of totally emissions-free flight, or up to 1,000 miles (1,600 km) using a gas turbine generator for reduced-emissions flight. Its unique diamond box-wing airframe would cruise at 30,000 ft, at speeds up to 345 mph (556 km/h), making it significantly faster than most other designs.

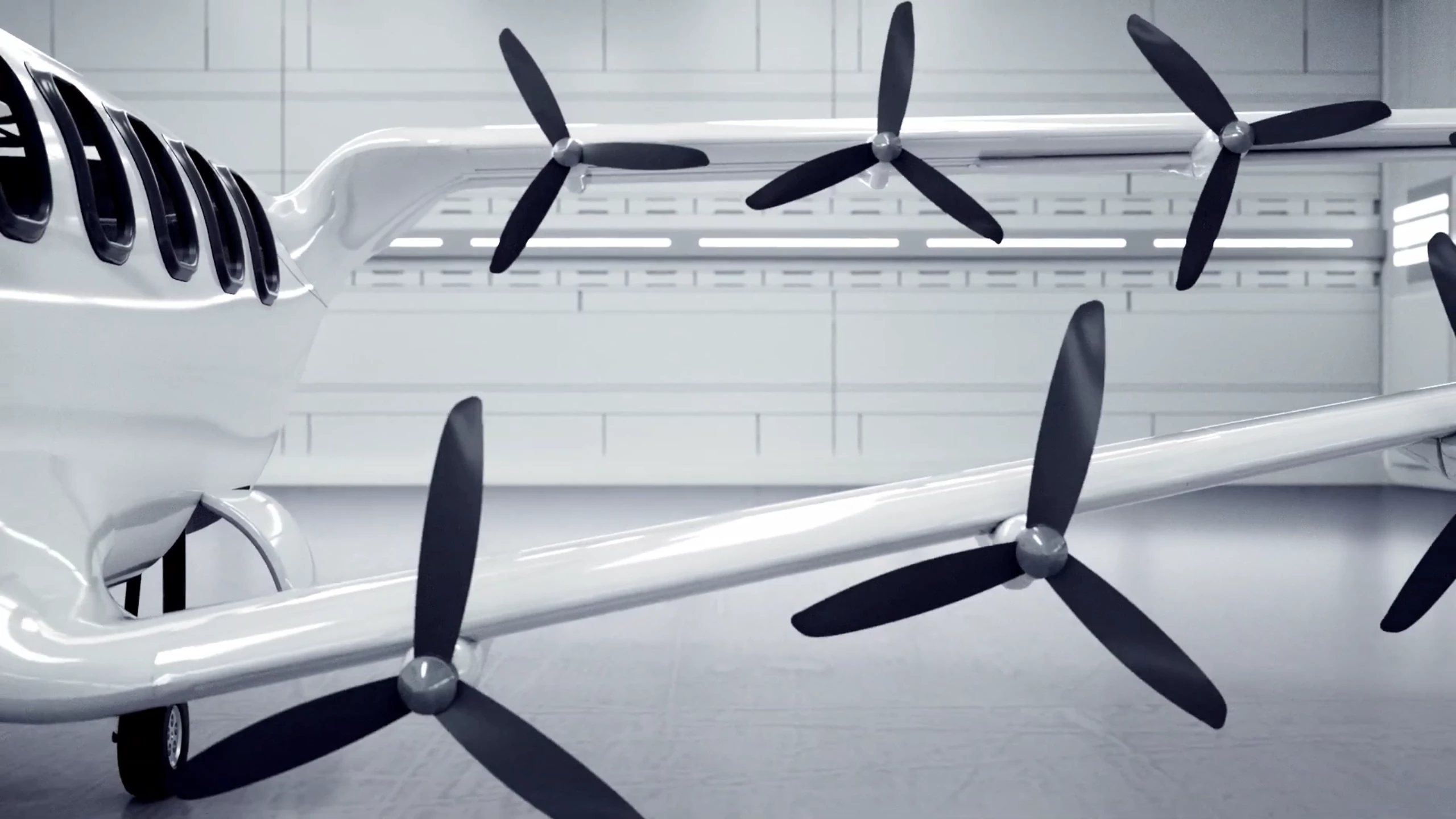

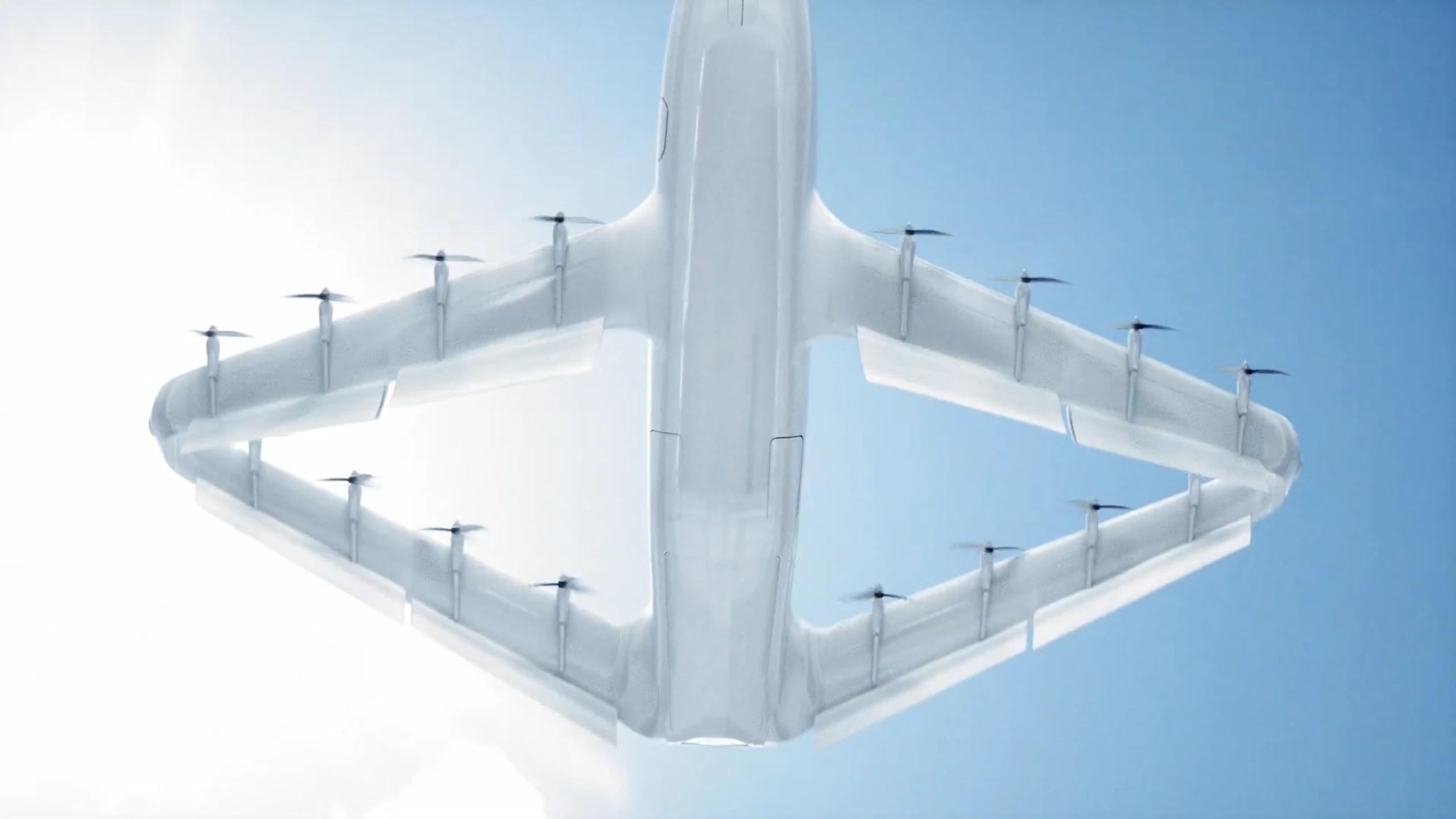

We were fascinated to learn that it won't be using redundant lift and cruise propellers, or tilting its wings or props, to achieve vertical takeoff and landing. Instead, the 16 props spaced out along its wings are rigidly mounted facing forward, and the aircraft will develop vertical lift at a standstill by extending large flaps from the back of each wing, to redirect the airflow and thrust from these props downward.

A Y Combinator graduate, Odys has recently announced a US$12.4-million seed funding round, bringing its total funding to US$13.7 million. It's flown small-scale prototypes, and is currently in the process of building a larger prototype with an 18-foot (5.5-m) wingspan, about a third as wide as the final design is expected to run.

We caught up with Odys co-founder James Dorris to learn more about the aircraft, the company's progress, and that unique blown-flap "deflected slipstream" VTOL system. What follows is an edited transcript.

Loz: can you talk us through the process that led to that diamond box-wing airframe?

James Dorris: The aircraft is really developed from a full systems perspective. If you think about doing a VTOL aircraft, and think about having tilt rotors or tilt wings, the size of those mechanisms and the mass and where you're putting failure modes ... We wanted to look at that and consider: is there a better way? One of the most challenging points in flight for a VTOL aircraft is the transition between hover to flight. When you're tilting things you can get some effects which cause some very challenging aerodynamics. We wanted to build an aircraft where that was a lot simpler.

That's where the deflected slipstream came from. Once you decide to look at deflected slipstream as a primary lifting mechanism, well, in order to really make this smart and fit in a compact footprint, you really want the tandem wing, a front wing and a rear wing, so that you can get really good pitch authority and pitch stability in the hover mode. It also gives us a lot of resiliency to center of gravity movements.

So once you have the tandem wing, the front and the rear wing, and you're looking at how to maximize the amount of propeller disc, and therefore reduce disc loading as much as possible to optimize for power, well, you want to have those wings be angled and so swept back and swept forward. You want to keep it within a good footprint so it can land it on traditional helipads, and hence you rapidly end up with this shape for the wing. There are some complexities that come along with the joined wing, and that's all part of the design.

Are you talking about flutter issues there? I know that's something AMSL Aero is concentrating on with its Vertiia box-wing.

Part of it's flutter issues, part of it's that certain wings can be loaded in compression as well as in tension, and you need to worry about some of the structural things that can happen in compression. We think the aircraft topology really has a strong benefit for being able to do both VTOL and to quickly transition out of VTOL as fast as possible, to get airborne on those wings as quickly as possible.

Our architecture really allows for that very efficient and smooth transition between VTOL hover and flight, it's a really good way to limit the amount of time you spend in a hover state, and its effect on overall aircraft efficiency.

So if tilt-prop and tilt-wing designs are more aerodynamically complex and challenging, are you saying it's less complex to have the fans blowing in one constant direction and just use these flaps to redirect the airstream and the thrust?

One of the ways you can think about our architecture is to take a traditional aircraft that has a flap that extends to 35 or 40 degrees. It has that flap so that it can stay aloft at slower speed. That transition from takeoff at just above the stall speed to full flight when those flaps are stowed is the same transition that our aircraft goes through from hover to fixed-wing flight. Except our flaps, instead of extending to about 35 or 40 degrees, they wrap further down to about 85 degrees. So you can think of our aircraft as the extension of a traditional aircraft where our stall speed approaches zero.

I know these things aren't going to spend a lot of time in a hover, but the first thing I thought when I saw this design was "surely that can't be as efficient for VTOL as just pointing the props down."

Yeah, so there's a couple of key metrics that we use to look at the efficiency of the deflected slipstream. One is the turning angle – so, instead of the jet of those propellers coming horizontally backward, how far do we bend it? So a turning angle of 90 degrees means that you're generating pure lift. The other is the turning efficiency: the total thrust coming out the back of that jet relative to the total thrust that would be at the propeller disc.

You are going to have drag as the airflow follows the path of that deflected slipstream flap system. And so really the question is, where's the optimum balance between those? Because the higher the turning angle, typically, the bigger the hit in turning efficiency.

So we've got some designs that we've got on our test stand showing a baseline design where we can start with a turning angle of 75 degrees. Seventy-five degrees means that the aircraft hovers stably in place with about a 15 degree nose-up angle. Incidentally, on takeoff, a 737 hits about 14 to 17 degrees. So nose up on takeoff is something that humans are quite accustomed to and comfortable with. That's a really good balance; we can get to turning inefficiency, where of course it's not 100 percent. But it is high enough that this technology, given the reduction in complexity and the simplicity in transition, is well worth it.

OK, and you're not prepared to share any figures around that?

Not at this time.

Can you give us an idea of where it might sit between something like the Lilium jet, which uses those tiny ducted fans and needs a lot of power to hover, and something like the Joby S4, which uses great big open propellers and should be more efficient?

When you talk about hover efficiency, you're asking about how much power does it take to lift the aircraft in VTOL? That's hard to talk about as an efficiency; the units are something like power per force lift. The biggest knob that changes that is the disc loading or the total propeller disc area. That's why something like Joby – with six really big rotors – has a lower hover power than something like Lilium. It's got nothing to do necessarily with ducts versus propellers versus deflected slipstream. It is primarily related to disc area. Our aircraft is very similar to a Joby in terms of disc loading. We get to line two sets of wings with propellers. There are some ways that the propellers get architected and laid out that help us effectively increase the disc area, reduce the disc loading, and keep our hover power low.

OK. Do you know roughly what kind of diameter props you'll be running?

Yeah, when it comes to these types of details, we haven't disclosed these and I'd be happy to give you these details once our conceptual design is fully baked and fully finalized.

Right. So you guys are going with a hybrid system at this stage for long range?

Yeah, we think of it as a gas reserve. Any battery-electric aircraft is going to have to carry a certain amount of battery for the reserve mission. Depending on whether it's a fixed wing or VTOL, the exact amount of energy that you need for that reserve mission could be different. Either way, the mass of that battery, or the fraction of that total battery that is used for reserve, is very large. Our baseline battery is not tiny and not gigantic, roughly the size of a few Model Y batteries!

Our hybrid system uses an aero-derivative gas turbine generator. It's very important that our turbine be known within the industry, have a lot of hours and durability, maintenance capability and known maintenance costs. The turbogenerator is quite light. The power electronics and the motor generator unit are our design, and that's what we're best in the world at – the electrification side.

So we can build the hybrid components of the system at a mass that is less than what we would have to carry in reserve battery weight. Now the reserve mission is in fuel, with a 60-to-1 benefit in fuel weight versus that battery weight. What that means is we can end up with an aircraft that can do about 200 miles (322 km) fully electric, but then it can go further – easily 400, 600 miles (648, 966 km). And even on a 400-mile mission, half of that energy usage still came from that battery, meaning that effectively we have a 50 percent reduction on the total CO2 for that mission.

OK. Will you be launching this as a piloted plane?

Yes. We're coming to market with both the left and right seats pilot-capable. A number of airlines have told us it's really important to have two folks in uniform, although we'll also certify it for single-pilot operation. We very much have a program for full autonomy, but we think that's a much longer time horizon than some folks do. So the first product is not an autonomous aircraft. It's human-piloted and autonomy is a longer-term plan.

But there will be automation from day one. There is going to be a significant amount of sensing onboard this aircraft. And some of the takeoff and landing capabilities will be heavily guided and automated by sensing and by smarts.

One of our favorite advisors used to be a Harrier pilot, and he would talk about the Harrier where when you move that stick, you're literally controlling the nozzles. So the control loop that's keeping that aircraft balanced is a human. It's a very difficult plane to fly. And he's like, now we've got the F-35, and all you have to do is put the thing on the thing and press the thing. You put the X on the landing pad and hit the land button, and the aircraft just lands. The technology has been there for a long time to enable this. It's quite possible and quite easy to make takeoff and landing heavily automated.

Right. So where are you guys at? You've just done this capital raise, which is terrific, congratulations. How far have you got, and what stage does this funding round get you to?

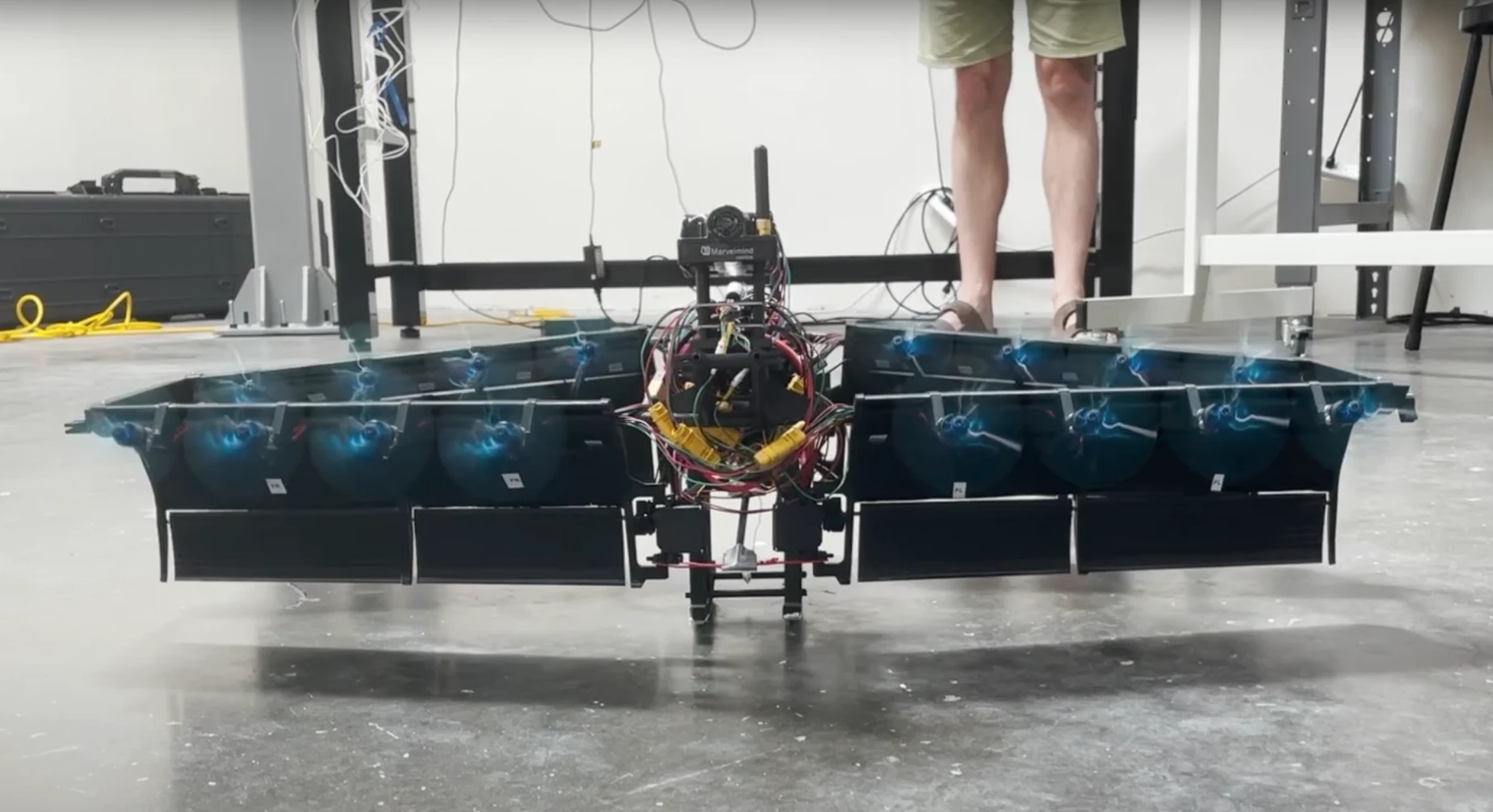

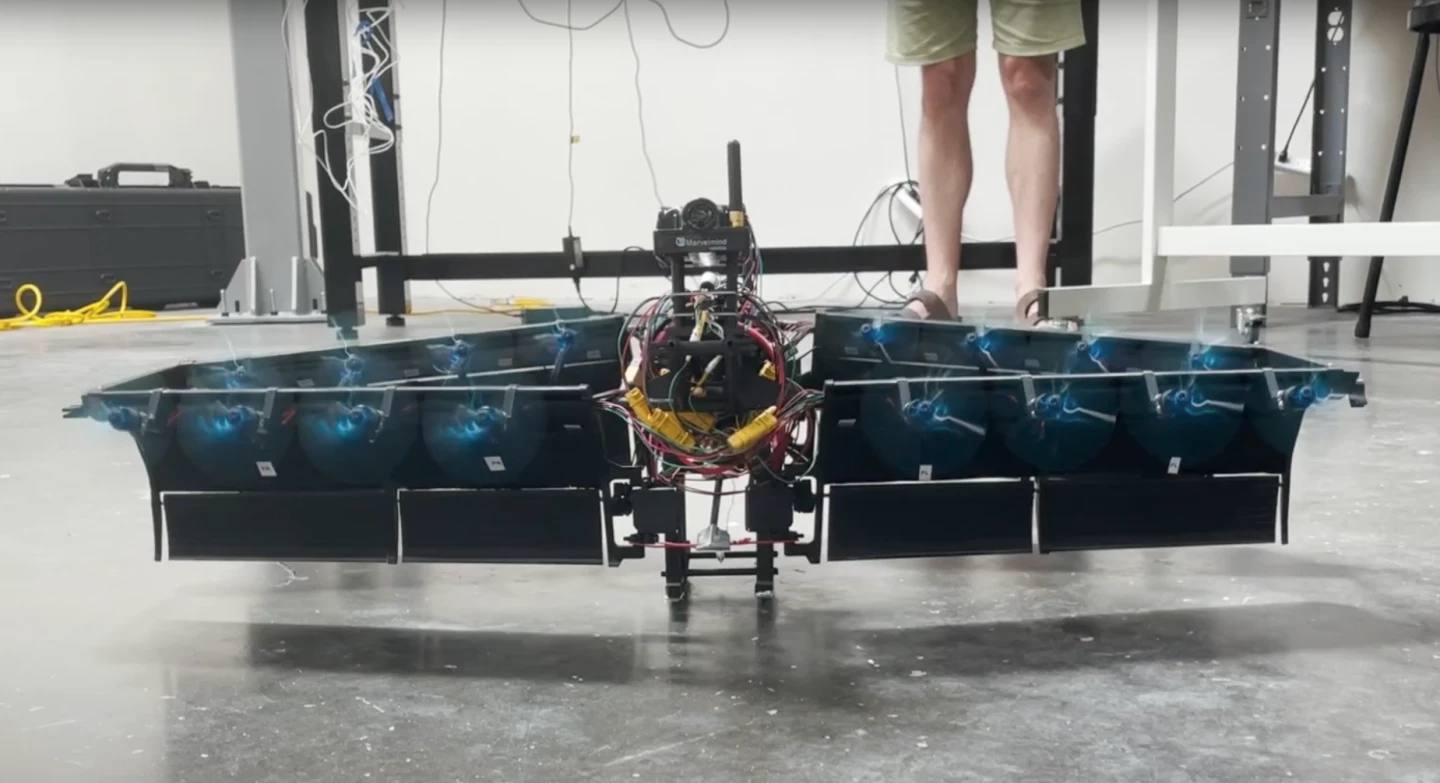

We've spent a lot of time validating that this way of taking off vertically works. We've built one with a three-foot (0.9-m) wingspan, I saw a screenshot of that in your original article. We've been flying that for the last six months to develop flight controls and build confidence in the capabilities, measuring performance metrics and projecting to what those can be at a larger scale. We think it'll scale into a very attractive performance machine.

OK, so you've got quadcopter-style pitch and roll authority validated with the deflected slipstream system. What about yaw? Quadcopters would normally rely on torque reactions for yaw movements, right? How do you guys manage that with all the props facing forward and the thrust directed down?

This is definitely a topic that I'll say we can talk about later. This is a core element to what we've developed, we're quite proud of it and when we're ready to chat I'll be happy to give you a ring and chat over beers!

So what milestones are we aiming for next? The next key technical milestone is building our next scale prototype – that's ostensibly a one seater. No human's going to fly in it, it'll be a remote piloted version of that aircraft, but it's about an 18-foot (5.5-m) wingspan, and it'll be the first version of our tech that does all phases of the mission together. It takes off vertically, transitions, pulls in the flaps, extends the flaps to fixed-wing flight.

In linear distances like wingspan, it's about a 1/3 scale. In terms of payload and area, it's about 1/9 or 1/10 scale. We kicked that off after this last raise in September last year. And our goal is to have the first flight test on that by fall of 2022.

OK, and if I remember correctly, you're aiming for this thing to be fully developed, built and in service by 2026? That's going to be pretty tight.

It's definitely aggressive. We're in the business of being aggressive for sure. Everyone is. We've validated our program and our certification path with some third parties who have been responsible for certification of vast numbers of aircraft, particularly a lot of Part 23 aircraft. So we think that gives us a good baseline. We fully acknowledge it is an aggressive timeline, and we think about the company and our funding cycles as such.

Are you partnering up to help bring down the costs and timelines of getting some of the bigger systems developed and built and certified?

All of the electrification will be developed in-house. That's what our team is the best in the world at; we can achieve a total system mass that's quite a bit less than if you're piecemealing it together off the rack from suppliers. The motors, the power electronics, the batteries, all these things have to be tightly integrated with one another and within the aircraft. We see that as a big advantage, whether we end up actually fabricating these systems ourselves or farming it out to a contractor.

Where we're not vertically integrated is in the gas turbine – we'd be nuts to try to develop that as a startup – and the avionics system. There's an enormous amount of man-hours in software development for an avionics system, and we'd be foolish to build that from the ground up. We are in discussions with a few avionics suppliers, we're in discussions with four turbine suppliers. I think we'll be able to announce some partnerships later this year.

OK. So you guys are coming in from a different angle than most eVTOL companies, looking at that regional air travel market rather than urban air taxi flights.

Yes. Compared to a lot of folks, we think that if you really want to make an impact, it makes sense to focus more on the regional journeys, say, 100- to 600-mile trips. If you really want to move the needle in reducing CO2 for aviation, well, you've first got to take people out of the gas-burning aircraft and put them in something else. So you need to get to distances that replace current trips.

At these distances, it doesn't matter if you're in the US, or Europe, or various parts of Asia, you might only be in the air for 45 or 50 minutes, but door to door times can be three and a half, four, four and a half hours. All that time you lose on the ground, going to the airport, going through the airport, waiting at the gates, getting delayed on the tarmac, etc, etc. So the two pillars of our company are really to reduce the carbon footprint of aviation, and just make travel way more enjoyable.

And this approach is striking a chord with airlines you're talking to?

We've signed up an LOI for pre-orders with JSX, a regional carrier here in the US. They really align with our vision of what regional transportation should be – they call it "hop on, hop off," we've got to shrink the pain between door to wheels-up. We've signed other deals too, but JSX is the only one we're allowed to message about today.

We've spent a lot of time talking to airlines – that's anyone from small part 135 operators all the way up to US majors and international mainline carriers. We're at a point now where we have enough pre-orders and options from airlines that we're very proud. We're feeling very good. The numbers are fairly surprising given just how early-stage we are.

And it's really a reflection that the airlines get that there's a lot more value if you can go further. That's the customer base that they fly around today. If you can decarbonize some of the shorter distance routes, you can really make an impact in your overall CO2 emissions. They care a lot about that. And if you can make their travel experience substantially better. We had one airline say, well, that might cannibalize some of our existing routes, but better I do it to myself than someone else does. And they get that. As soon as you can do a regional route where you don't have to go to a big airport, no-one's going to fly that regional route out of the airport.

We thank James Dorris for his time and assistance on this piece.

Source: Odys Aviation