One of the world's largest tier-one auto parts suppliers claims it's created the "perfect motor." The compact Mahle motor uses no rare earth magnets, transmits power without contact or wear, and can run at high power indefinitely without overheating.

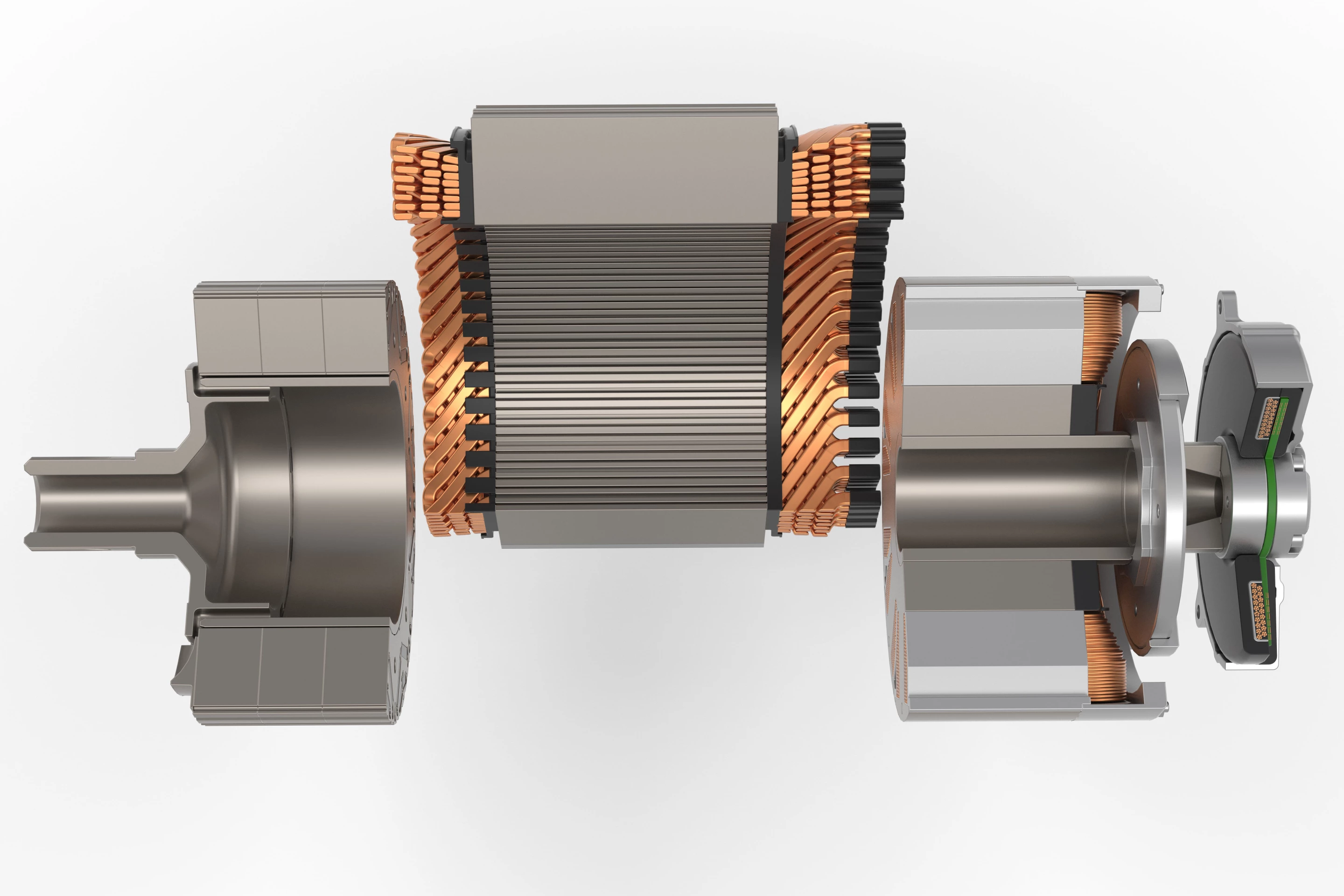

It's the combination of two impressive concepts Mahle released in 2021 and 2022. The first was the cheap, highly efficient MCT (Magnet-free Contactless Transmitter) motor, which replaced the typical permanent rare earth magnets in the rotor with a series of wound-coil electromagnets, and powered these magnets using contactless induction.

This brought down the price of materials, and eliminated the necessity to run supply chains through China, which refines some 97% of the world's rare earth metals. It was also remarkably frugal with energy, operating at more than 95% efficiency right through its range of operating speeds – a level Mahle said at the time had only ever been achieved by Formula E race cars.

The second was the SCT (Superior Continuous Torque) motor, which debuted a pioneering new cooling system. Most electric motors have quite a decent gap between their peak power rating and their continuous power rating, since overheating can cause serious damage. So manufacturers put vehicles into a thermal management mode, cutting down the power until the temperature comes down.

The SCT motor, though, uses a central intake to send cooling oil into the middle of the rotor, and uses the centrifugal force of the spinning rotor to pump it outward and around the stator, then through to a radiator, or else another system to harvest heat for use elsewhere in the vehicle.

It cools the motor so effectively that it can run all day at between 93-100% of its peak power. The benefit here is obvious in performance terms, but it also means manufacturers don't have to use oversized motors to guarantee performance at higher temperatures – they can save space and weight with the compact SCT design.

Mahle hinted in 2022 that the two concepts could be combined, and has now done just that.

The new "perfect motor" is as yet nameless, but it uses the SCT's cooling concept in the MCT's magnet-free, induction-powered design, and Mahle says it retains the advantages of both these systems, offering extreme efficiency, sustained high performance without overheating, exceptionally long life, and harvestable heat. And it uses no permanent magnets, so it should be cheap to build as well.

Mahle is presenting it as a "technology toolbox" for OEMs at this year's IAA Mobility expo in Munich. There's no word as yet on when we'll see a production version – that's likely up to the auto manufacturers.

It's worth pointing out that the company itself puts those sarcastic-looking quotation marks around "perfect motor" in its own press release. But it sure seems like Mahle believes it's created something special here.

Source: Mahle