Chicago-based nonprofit World Bicycle Relief (WBR) doesn't distribute just any type of bicycle – it distributes bicycles meant to navigate the unimproved roads and rough terrain of developing nations, empowering populations to access healthcare, education and economic opportunities that would otherwise be out of reach.

It declares its original Buffalo Bicycle the strongest available for holding up to rural terrain, and it didn't take the task of redesigning it lightly. With the Buffalo S2 Utility, it's reworked the simple concept of a chain, gears and pedals into a rarely-seen unicorn: a two-chain drivetrain.

The first thing that comes to mind when looking at a two-chain setup is ... Why??! It looks like the layout adds extra weight and complication, plus an extraneous ripe-to-break chain, just to go against the conventional layout of shifters and rear cogs.

But that's an industrialized-world first impression of a developing-world solution, and while it's probably a fair question for an urban commuter bike aimed at North Americans or Europeans, it misses the mark on a bike built specifically to be an extra-durable daily workhorse ... like a Land Cruiser 70 Series for those who can't afford a Land Cruiser 70 Series, or have no way of accessing one.

World Bicycle Relief explains that its Buffalo bicycles are designed to be "extremely durable to serve the needs of people who travel long distances over rugged terrain with heavy cargo in some of the world's harshest environments." With that in mind, simplicity and ruggedness are absolutely critical, and the redundant chain system is designed to provide a high/low gear solution that involves as few breakable, externally mounted parts as possible. These bikes are being delivered to places that don't have access to bicycle shops or spare part overnighting, so making something that's as tough and easy to repair as possible is an essential part of WBR's job.

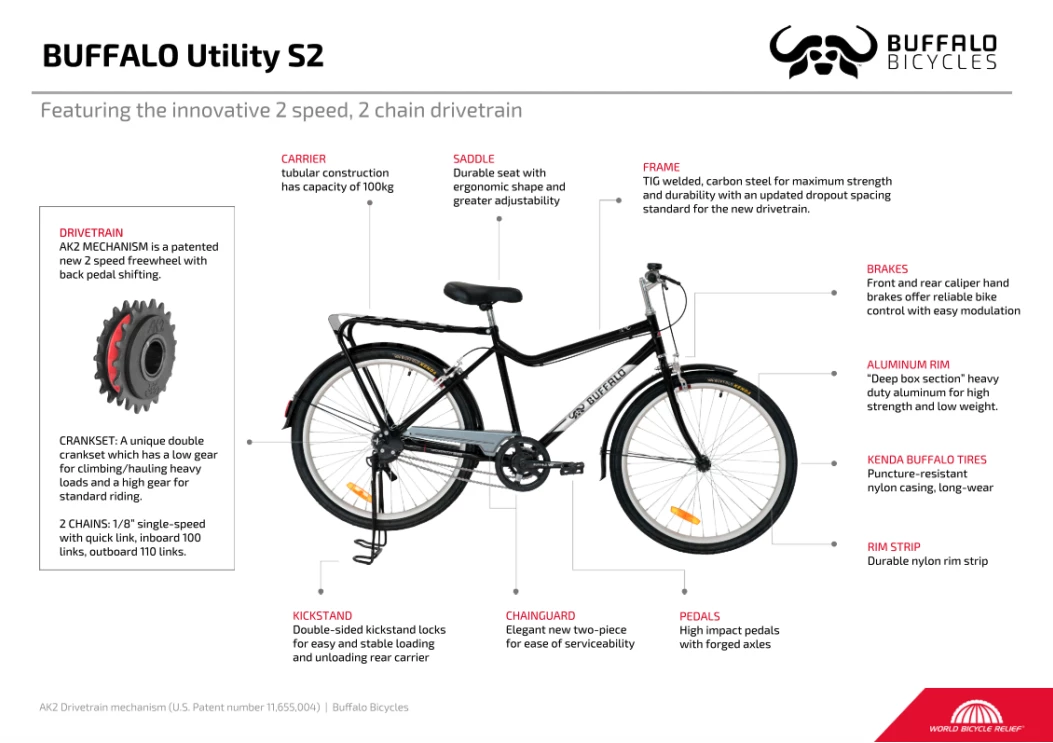

The original Buffalo Bicycle was a single-speed for those reasons, but WBR identified the need for a low gear designed to ease climbs and cargo hauling. Instead of equipping the bike with a bunch of cogs, cables and added components, it's split the powertrain out into two separate drives: a high chainring connected to a rear cog via a dedicated chain and a low chainring chained to a second rear cog on the same hub. All hardware is located on the right side of the bike, and the rider simply backpedals half a revolution to activate the switchable freewheel from high to low and vice versa.

A bicycle designed with two chains isn't unprecedented, but it certainly isn't standard fare at any bike shop we've browsed. We've seen a pair of asymmetrical chains used to make the ride less slappy, and we've seen an electric bike with dedicated high-power motor and pedal chains, but nothing quite like Buffalo S2. WBR calls its layout an industry-first and received its first US patent for what it's branded the AK2 Freewheel.

While chains are certainly subject to break like any other component, they can generally be easily field-repaired with a chain tool and spare link(s). And given that the Buffalo S2 Utility has two separate chains, it can still be ridden home even if the one chain is damaged beyond field repair.

The rest of the S2 Utility is designed to be equally simple and robust, centered around a TIG-welded carbon steel frame. Heavy-duty "deep box section" aluminum rims and puncture-resistant Kenda Buffalo tires keep it rolling forward. WBR says the dual-pivot caliper brakes are specced for easy operation and adjustment, the tubular rear rack built to carry up to 220 lb (100 kg) of cargo.

Before debuting it at Eurobike 2024 this month, WBR developed the Buffalo S2 with help from global bicycle and component manufacturers and spent two years testing it in Sub-Saharan Africa and South America, ensuring it met the needs of its end users. It took home a Eurobike Award for the design. Since its founding in 2005, the organization has delivered more than 800,000 bicycles to communities around the world, well on its way to its next goal of 1 million.

Source: World Bicycle Relief