A team from the University of Illinois and UC Berkeley has demonstrated a new cooling method that sucks heat out of electronics so efficiently that it allows designers to run 7.4 times more power through a given volume than conventional heat sinks.

Heat is very much the enemy for electronics designers, and it's one of the key limiting factors preventing electronics from getting smaller. If heat can't be ejected from circuits, they break down functionally, and sometimes physically. The familiar stacked-wafer shape of heat sinks is designed to conduct heat away from sensitive areas and dissipate it where it won't cause trouble, but the team says they typically can't remove heat from the underside of devices, where a lot of it is generated.

Next-generation heat spreaders seek to improve on the traditional heat sink, but the team says they're typically made out of expensive materials like diamond, and they often can't mount directly to the surface of the components without a layer of "thermal interface material" that improves contact, but can inhibit thermal performance.

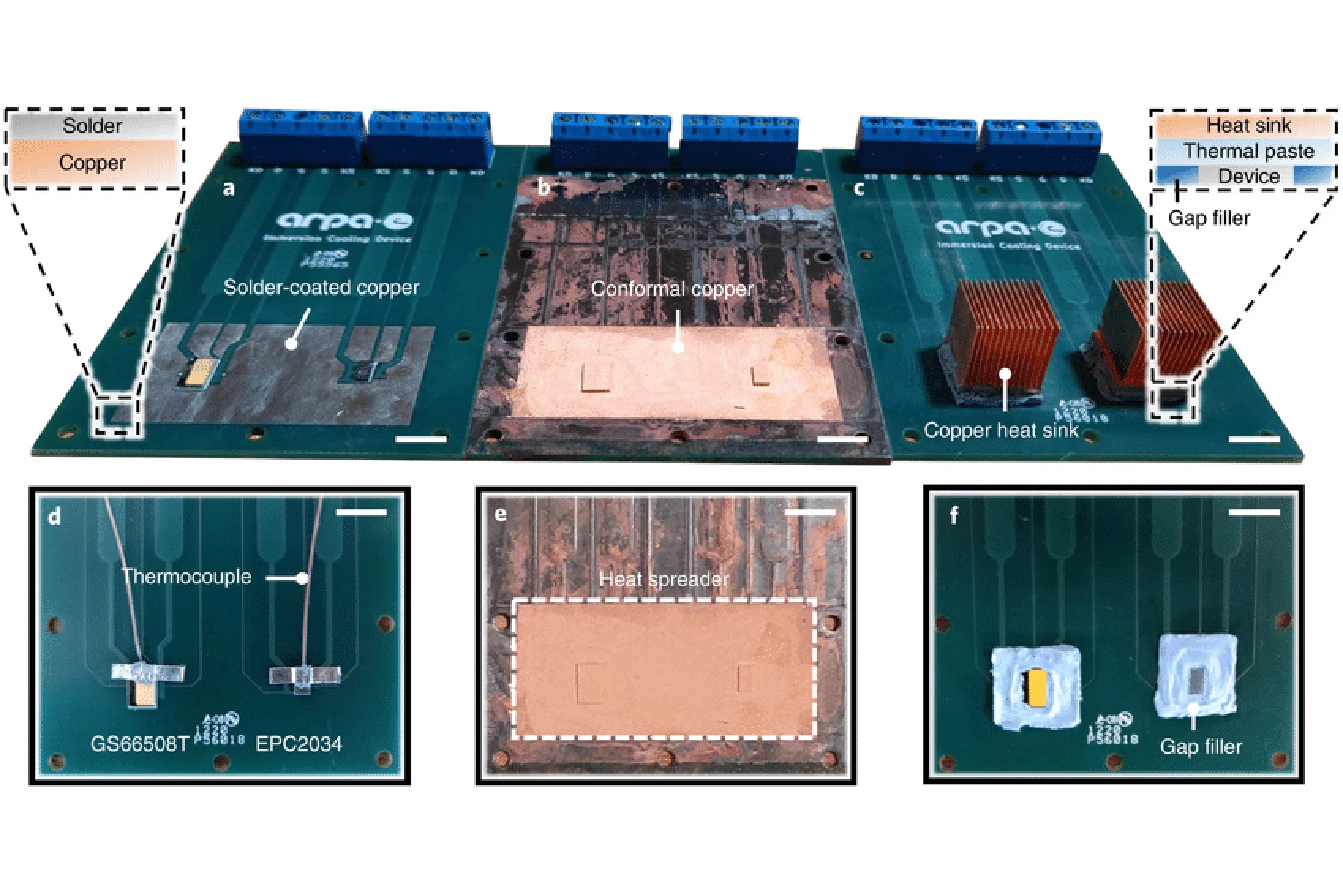

The team has come up with a solution they say radically boosts heat ejection without introducing costly materials. A new study published in the peer-reviewed journal Nature Electronics describes an approach that "first coats the devices with an electrical layer of poly(2-chloro-p-xylylene) (parylene C) and then a conformal coating of copper. This allows the copper to be in close proximity to the heat-generating elements, eliminating the need for thermal interface materials."

Essentially, this new cooling system completely covers all exposed surfaces of the electronics, including the top, the bottom and the sides. The device and the heat spreader act as a single piece, which performs as effectively, or more effectively, than a heat sink, without anywhere near the bulk of one. The team tested this ultra-efficient passive cooling approach successfully on some gallium nitride power transistors.

For a single circuit, they recorded impressive results – but the effect is greatly multiplied when you can stack them on top of one another. “Let’s say you have multiple printed circuit boards,” says lead author and UIUC Ph. D student Tarik Gebrael. “You can stack many more printed circuit boards in the same volume when you are using our coating, compared to if you are using conventional liquid- or air-cooled heat sinks ... And this translates to much higher power per unit volume. We were able to demonstrate a 740% increase in the power per unit volume.”

The research confirmed that this conformal copper coating is suitable for use in both air- and water-cooled applications, although further testing is needed to see how durable this solution will be in boiling water, boiling dielectric fluids, high-voltage applications, and in circuits more complex than the simple test rigs used in the study.

The paper is available in the journal Nature Electronics.

Source: University of Illinois