Much of the research exploring how to improve today’s lithium batteries centers on the material used for the electrode, which stores the ions to generate the electrical current. While graphite is our current go-to, alternative materials promise better performance but compromise on other important aspects, including safety. Scientists at Purdue University have now come up with a design they say allows an advanced electrode material to combine performance and safety, by first fashioning it into a net-like structure called a nanochain.

Scientists are looking at a variety of better-performing materials as candidates to succeed the graphite generally used for lithium-ion batteries, but they often present other complex challenges, such as being too heavy or too irregularly shaped for use in commercial products. As researchers continue tinkering away in an effort to iron out the kinks, a team at Purdue University is claiming a big breakthrough concerning a metalloid known as antimony.

Antimony has been in use for thousands of years, with Egyptian artifacts such as vases found to contain the metal, and Egyptian women even believed to have used it as a form of eyeliner. These days it can be found in flame-retarding materials, television screens and other electrical devices. The interest among battery researchers comes from the material’s proven ability to enhance the charging capacity of experimental lithium-ion batteries.

But building it into the kind of lithium-ion battery that could power smartphones, for example, has proven tricky so far. Researchers have found that using antimony metals and others like it for the electrode component causes the material to expand to up to three times its original size as it charges.

“You want to accommodate that type of expansion in your smartphone batteries. That way you’re not carrying around something unsafe,” says Vilas Pol, a Purdue University associate professor of chemical engineering.

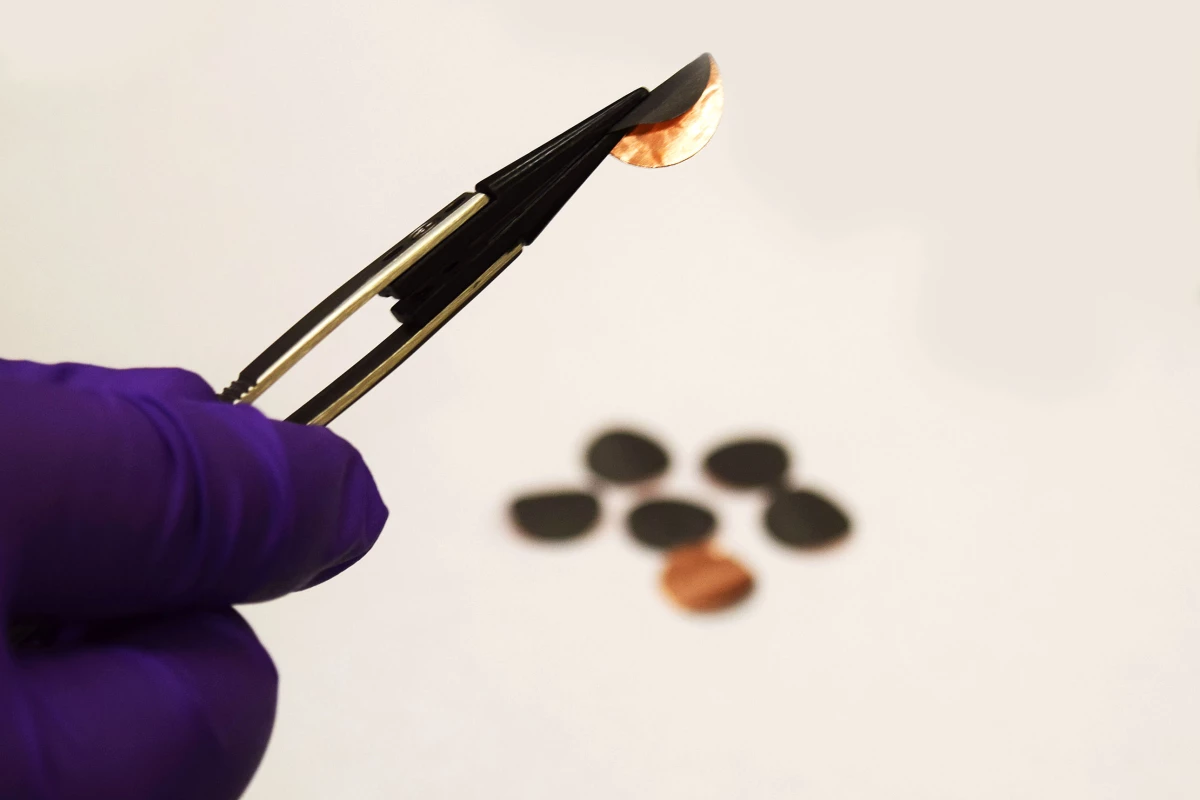

Pol and his colleagues have come up with a design that may well solve this key shortcoming. The team added a reducing agent called ammonia-borane along with a nucleating agent to the mix, which enabled them to conjoin tiny, individual particles of antimony into a web-like structure. Key to this is the ammonia-borane, which creates voids within the nanochain and therefore allows the material to expand without failing.

The team found that the approach worked only when applied to a specific type of antimony compound called antimony-chloride. They tested out the nanochain’s battery component credentials in the lab and found that it kept the lithium-ion capacity stable over 100 charging and discharging cycles.

“There’s essentially no change from cycle 1 to cycle 100, so we have no reason to think that cycle 102 won’t be the same,” Pol says.

From here, the team plans to test out the nanochain electrodes in pouch cell batteries to see how they hold up.

The research was published in the journal Applied Nano Materials.

Source: Purdue University