Researchers at Australia's national science agency have developed an efficient method to produce green hydrogen for energy-hungry, high-temperature industrial processes – and it starts with concentrated sunshine.

Heavy industries like steelmaking, and iron and alumina production, utilize hydrogen because it can replace fossil fuels in combustion processes while producing only water vapor as a byproduct instead of CO2 emissions. That's all well and good, but producing hydrogen through processes like electrolysis consume a lot of energy too. Greenifying the production of hydrogen itself is another crucial step towards reducing the impact of these industries on the environment.

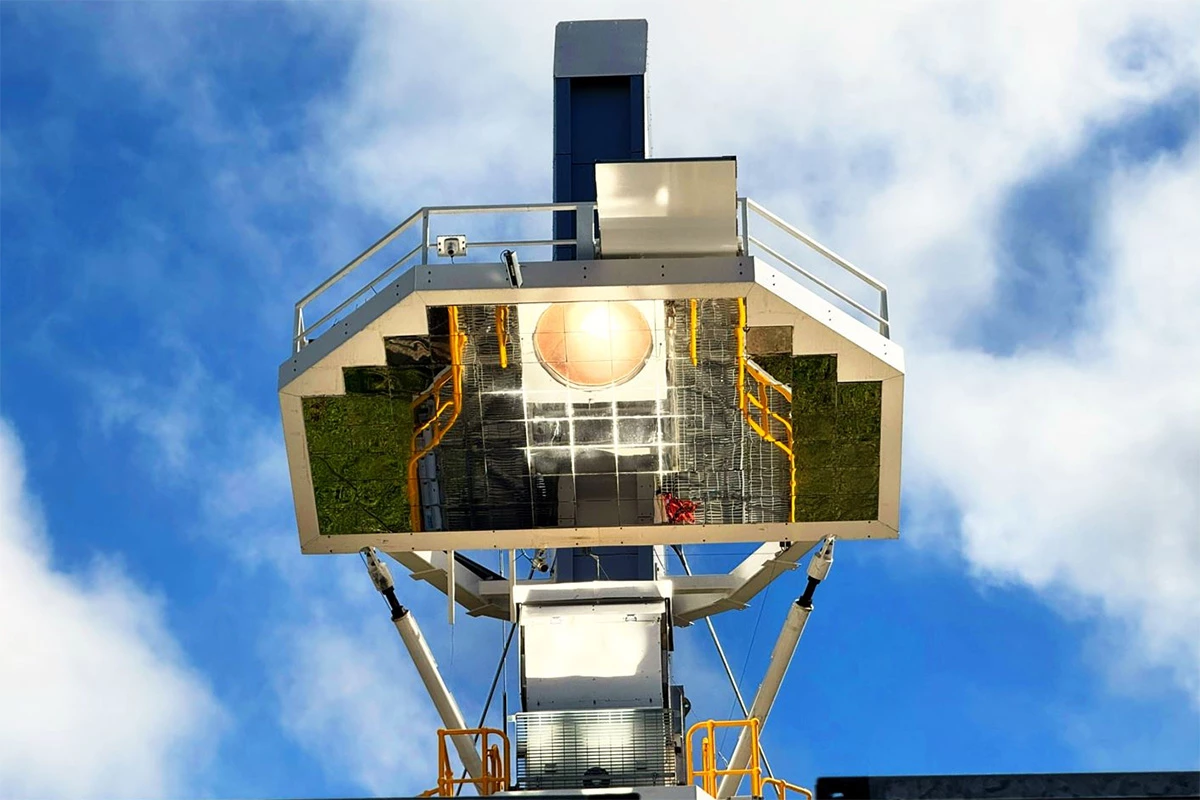

That's what the Commonwealth Scientific and Industrial Research Organization (CSIRO) in Australia is hoping to accomplish with its latest breakthrough, the beam-down solar reactor. While the concept appears to have been first developed years before, it's the first time it's been demonstrated in Australia.

Here's how it works. The beam-down reactor uses a large array of sun-tracking mirrors to reflect a whole lot of sunlight onto the top of a central tower. This tower then redirects the concentrated sunlight downward to heat a solar reactor that contains particles of a mineral oxide called ceria – or rather, a doped version of it. Modifying the oxide helps enhance its ability to absorb and release oxygen, and enables it to do so at a lower temperature than it otherwise would. The reactor is designed to split water into hydrogen and oxygen. It's aided by the doped ceria catalyst and this releases some amount of oxygen. When exposed to steam, the oxide absorbs oxygen from water, and leaves hydrogen behind for the taking.

The CSIRO team's solar thermochemical process showed that this system could achieve a solar-to-hydrogen efficiency higher than 20% – making for a significant improvement over existing processes, which manage about 15%.

What's more, the doped ceria catalyst can be reused multiple times. All this adds up to a promising path forward in decarbonizing critical energy-intensive industries.

There's work to be done yet. The team believes it's developed an understanding of how it can further improve the process before deploying it widely. "We’re not yet at industrial scale, but we’ve demonstrated strong reactivity under relatively moderate conditions, and with further refinement, it could match electrolysis in both performance and cost," CSIRO's Dr. Jin-Soo Kim noted.

If this has piqued your interest about the wonders of solar energy, you'll want to check out this startup that aims to beam solar power from satellites in orbit to receivers on Earth, the largest solar energy plant on the globe that's currently in the works, and this wild plan to slot solar panels in between railway tracks.

Source: CSIRO