The tons of discarded mussel shells generated by the seafood industry may be organic, but they're still very slow to biodegrade in landfills. They may soon find new life, however, sandblasting jeans in the textile industry.

In order to get that funky, fashionable, "lived-in" look and feel, denim jeans are typically subjected to a number of treatments on the factory floor. One of the most common of these treatments is sandblasting.

In the past, plain old silica sand was widely used for this process.

Due to its free silica content, however, it was causing high rates of deadly silicosis among workers. Although such sand still is used in some factories along with protective breathing apparatus (or without it, in less reputable factories), many locations have now switched to garnet sand, which contains virtually no free silica.

Garnet sand also performs better than silica sand at sandblasting, but it's significantly more expensive, plus it's a non-renewable resource. With those and other limitations in mind, scientists from Spain's University of the Basque Country looked to discarded mussel shells that would otherwise end up in landfills.

The researchers devised a process in which the shells are washed, sterilized via a thermal treatment, ground in a mill, and then sifted. The resulting grit is shot onto denim at high pressure, using a conventional compressed-air sandblasting gun.

Testing showed that the mussel shell grit is less brittle than garnet particles, and thus less likely to break during the blasting process. As a result, it performed better, requiring a smaller amount to sandblast a given number of jeans. It also reportedly left the fabric pleasing to the eye, and soft to the touch.

The grit could be repeatedly gathered up and reused over multiple sandblasting sessions, until the particles did eventually break down into fragments that were too small to use again. At that point, the grit could be composted much more easily than intact mussel shells.

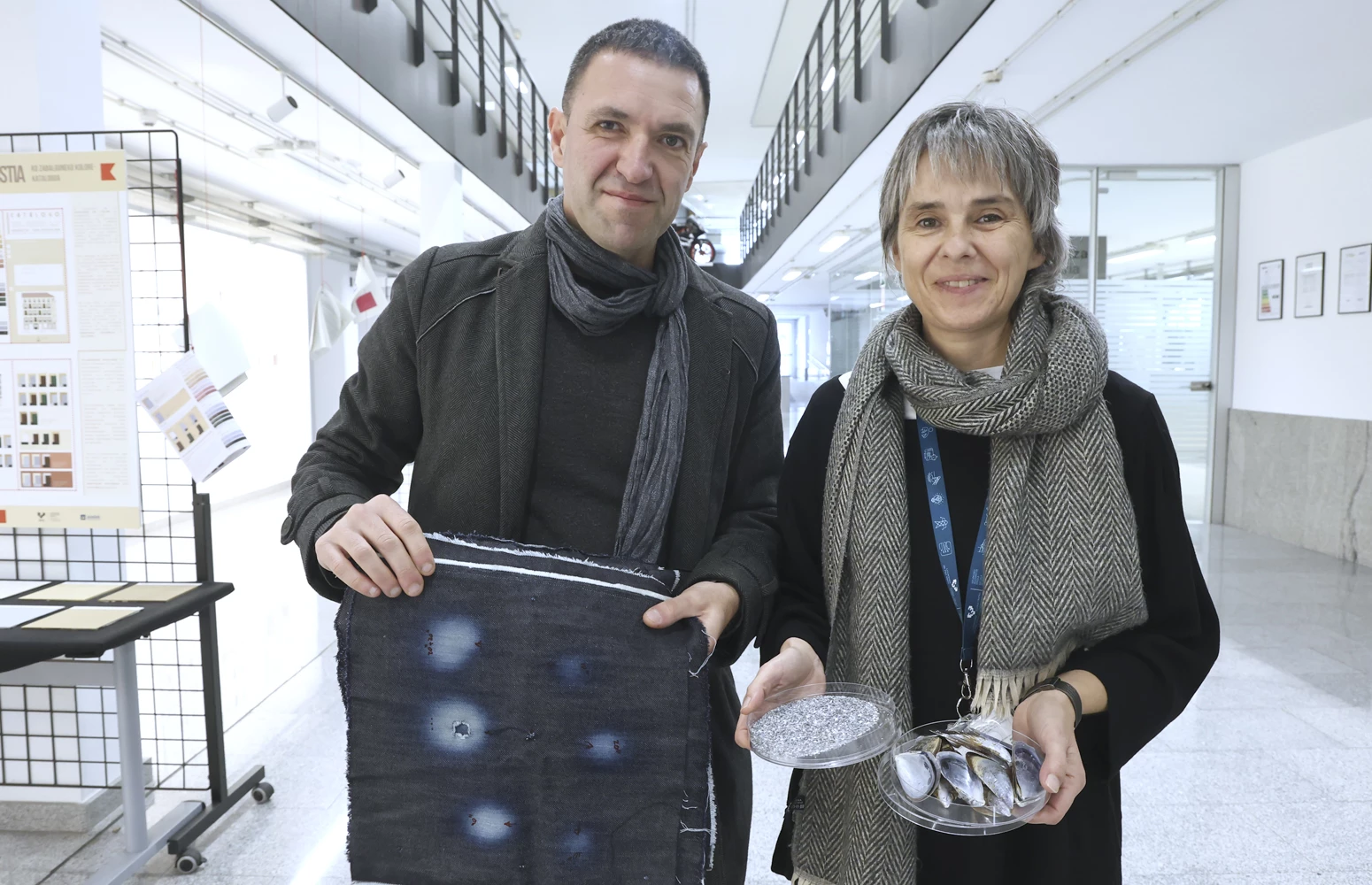

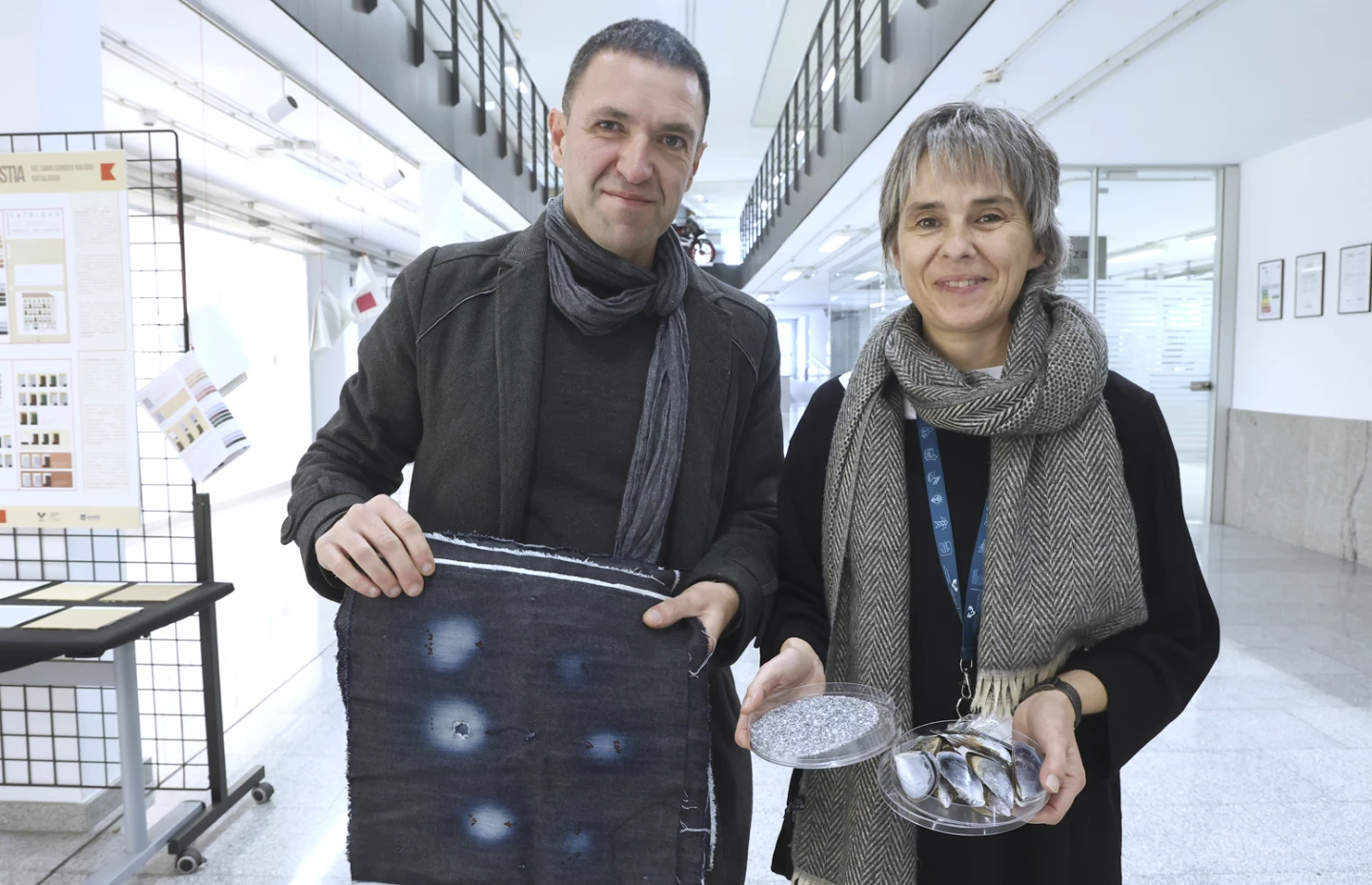

"It was a major piece of work and it took us time to achieve these results, but we are delighted with the achievement," says Dr. Juan Luis Osa, who led the study along with Dr. Cristina Peña. "We have verified a specific application to abrade denim, but in addition to that, the results have revealed that mussel shell grit has many other applications; it could be a suitable abrasive material and could be useful in other industries, such as the cleaning of mechanical parts or ships."

A paper on the research, which was conducted in collaboration with MIT, was recently published in the Journal of Cleaner Production.

Source: University of the Basque Country