Graphene may be versatile, but there’s one thing it’s not all that good at – dispersing in water. Now, researchers at Umeå University have found a relatively simple way to do it. Graphene oxide is a different form of the material that can make for stable water dispersion, which can then be used as a kind of graphene paint.

Graphene is essentially a two-dimensional sheet of carbon atoms, arranged in a hexagonal pattern. This deceptively simple material has a range of useful properties – it’s incredibly lightweight, thin and flexible, but still strong. It’s also an excellent conductor of electricity and heat, so it’s turning up in everything from electronics to water filters to clothing.

Ideally, one useful way to get graphene into the right configurations could involve dispersing it in water. This solution could then be painted or sprayed onto a surface to make, for example, supercapacitor electrodes or conductive coatings.

The problem is that graphene and similar forms of carbon, like graphite and carbon nanotubes, are hydrophobic, meaning they repel water. They can be made to disperse using harsh organic solvents or mechanical treatments, but the former is toxic and the latter can introduce defects.

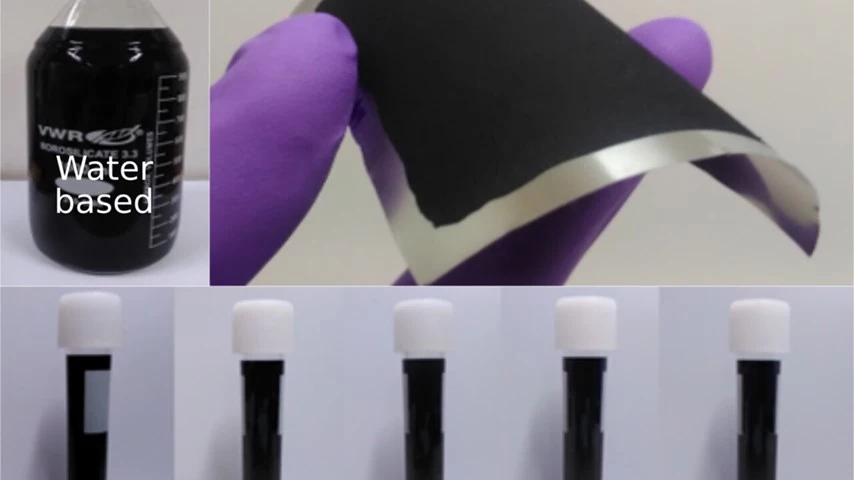

Now, the Umeå team has found a surprisingly simple way to make graphene dispersions. The secret is to use oxidized graphene instead, which is hydrophilic. By combining graphene oxide with particles of other hydrophobic carbons, such as graphene, activated graphene, porous and activated carbons, they managed to make stable graphene dispersions. After a few days, no material had settled at the bottom.

In one test, the team added carbon nanotubes and tried to make supercapacitor electrodes out of the mixture. They applied the dispersion to metallic foil, then dried it and heated it to 200 °C (392 °F).

“What we get in the end is a thin film of conductive electrode material with rather high surface area, good conductivity and excellent performance in storage of electricity in supercapacitors,” says Alexandr Talyzin, corresponding author of the study. “The high surface area is provided by the micrometer-sized particles of (for example) activated graphene, while nanotubes and thermally reduced graphene oxide provide good electrical contact between the particles.”

The researchers say that this new method could be easily scaled up for industrial production. They’ve applied for a patent for the technique.

The research was published in the Journal of Physical Chemistry Letters.

Source: Umeå University