Nearly six months ago, Figure announced its gleaming silver humanoid robot had got its first job working at a BMW manufacturing plant. It's been training up for the occasion, and new video shows how far this general-purpose worker has come.

There's a ton of these AI-powered humanoids under development at the moment, with all sorts of different hardware and learning approaches, but they're all focused on the same goal: taking over any physical task a human can do, and doing that job cheaper and more consistently.

The more they learn to do, the more robots these companies can sell, potentially decoupling economic growth from population figures and unlocking a source of labor that's limited only by resources. It sounds like a wild fever dream, but the hardware looks surprisingly capable, and while the AI models that train and control these robots are certainly still at a toddler stage of development, they definitely seem to be advancing at an impressive pace.

It really hits home just how different these machines will be from traditional industrial robots when they start talking back – in Figure's case, using a voice engine and language model from OpenAI:

A true general-purpose humanoid is still a long way off, but the companies building them want to get them doing simple useful tasks in real-world customer operations as soon as possible. It's probably more to gather data and educate customers about how to work with these next-level AI employees than as a real revenue source, but either way, car manufacturing seems to be a key industry for early humanoid robot adoption.

Apptronik, for example, has done a deal with Mercedes to trial its Apollo bot. Even the venerable grandaddy of this segment, the Boston Dynamics Atlas robot, has been shown training for auto manufacturing tasks.

Tesla, of course, has its own enormous car production facilities in which to train, test and get some early value out of its Optimus bot – although Figure Founder Brett Adcock seems to think this in-house approach might be too easy on the Tesla robot, tweeting, "Having an external customer, which will fire us if we fail, will be a competitive advantage for Figure."

Today, we get to see how the Figure bot is going with training, in the fully autonomous 'BMW Full Use Case' video below:

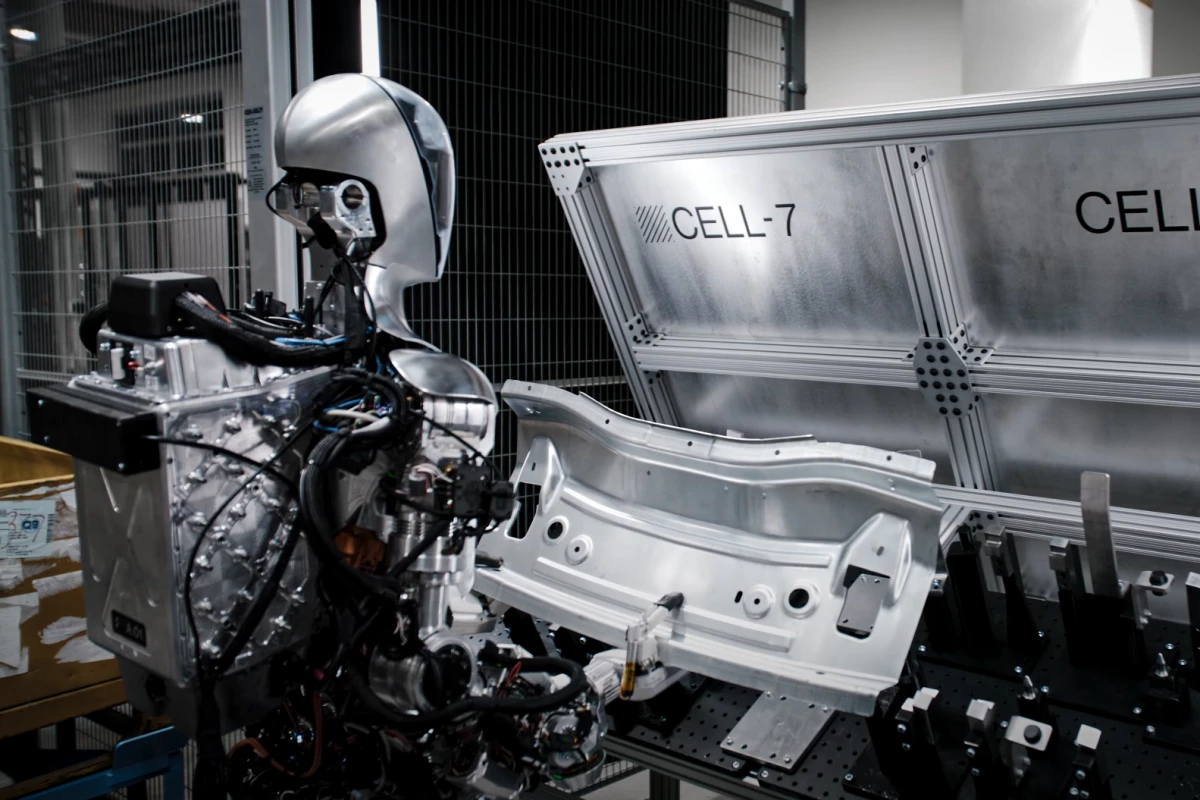

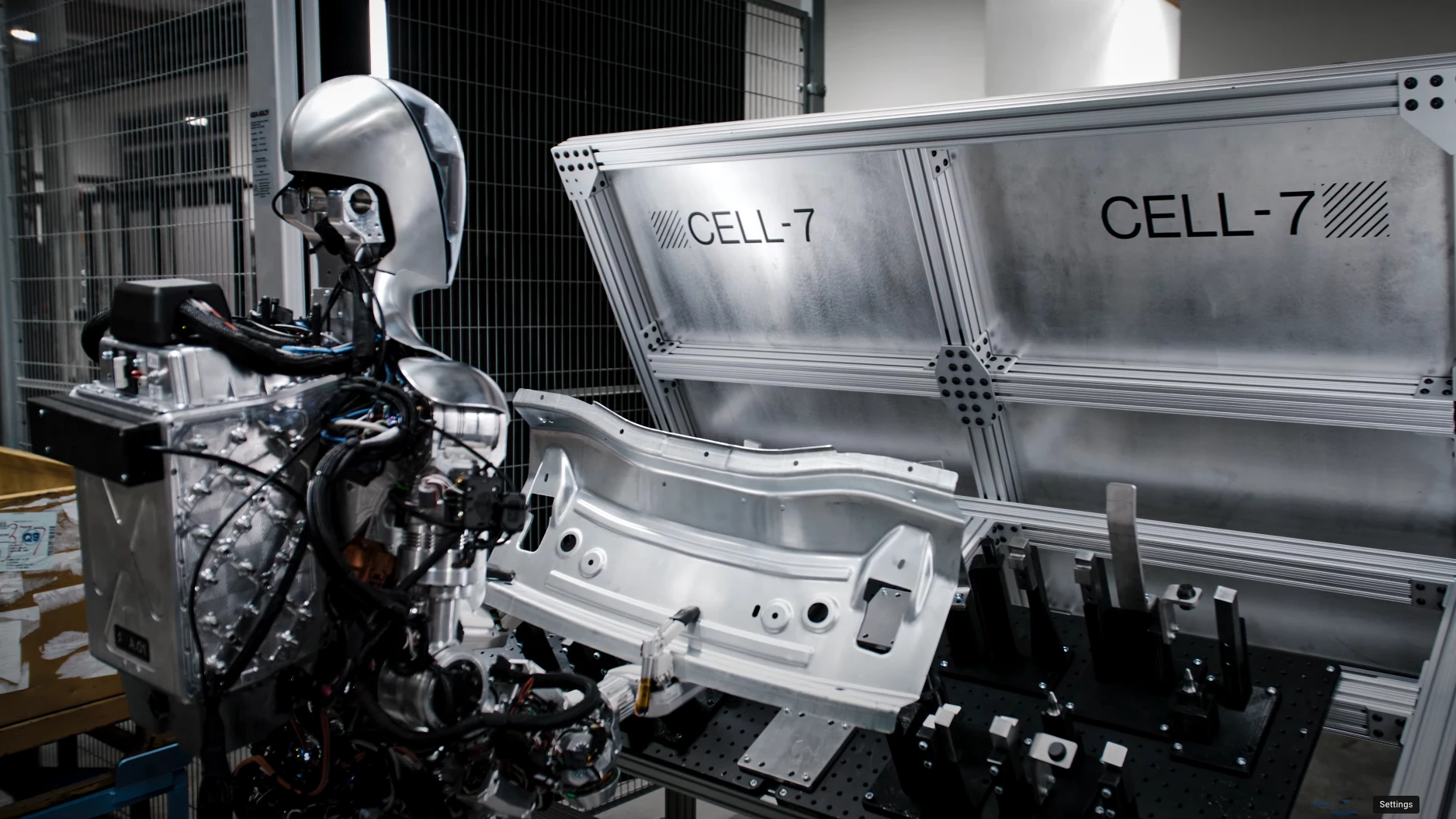

It's certainly not the most Earth-shatteringly amazing humanoid robot video we've seen, but there are plenty of positives here; the 01 is learning to grasp large, complex shapes with its rubber-tipped fingers. It's learning to move them around without banging into things – a skill I don't know that I'd endorse my own kids for yet at this stage.

It's no small achievement, either, to be able to place a large plate down on that jig with the plate blocking the two locating pegs it needs to get through the holes.

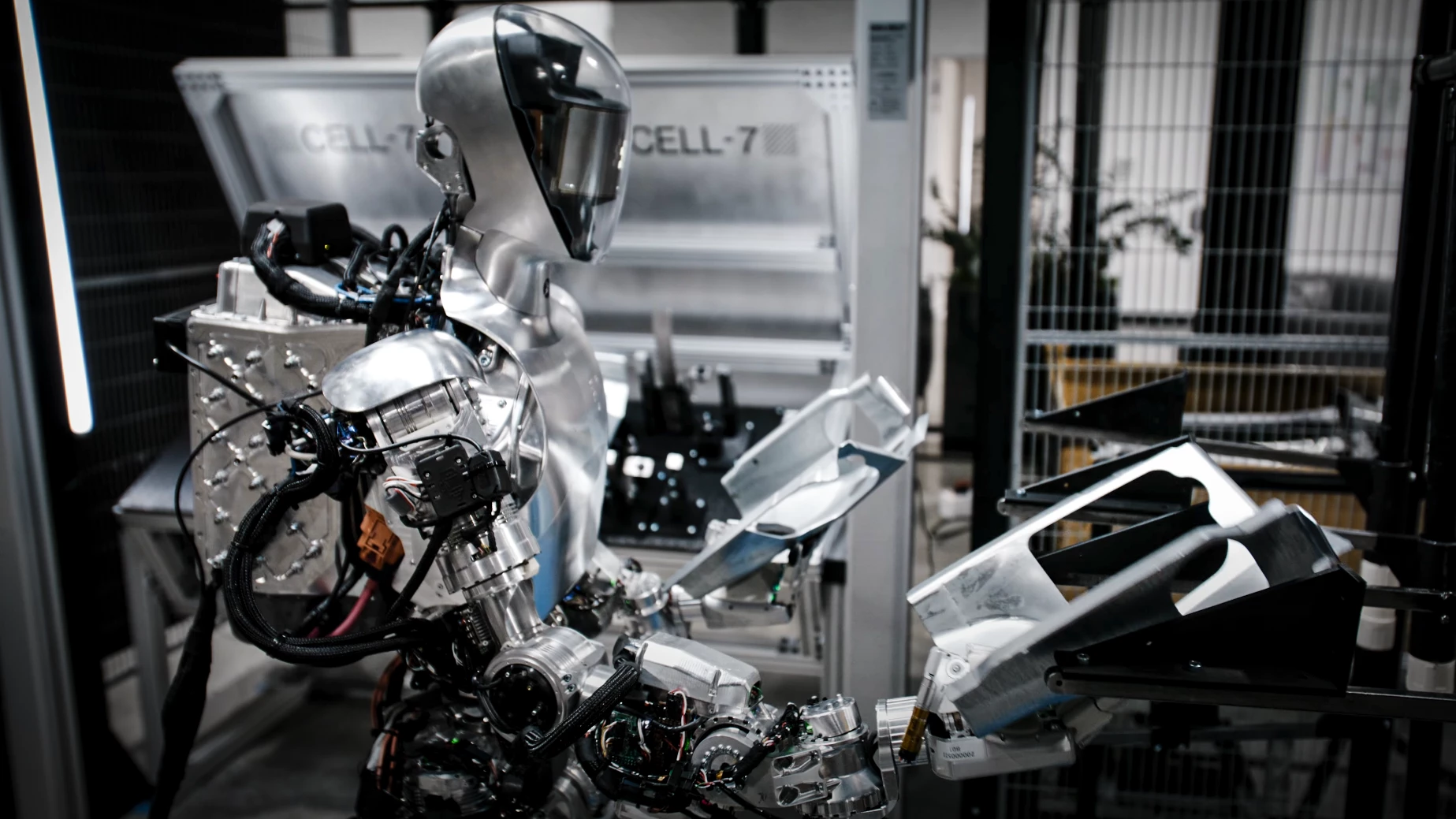

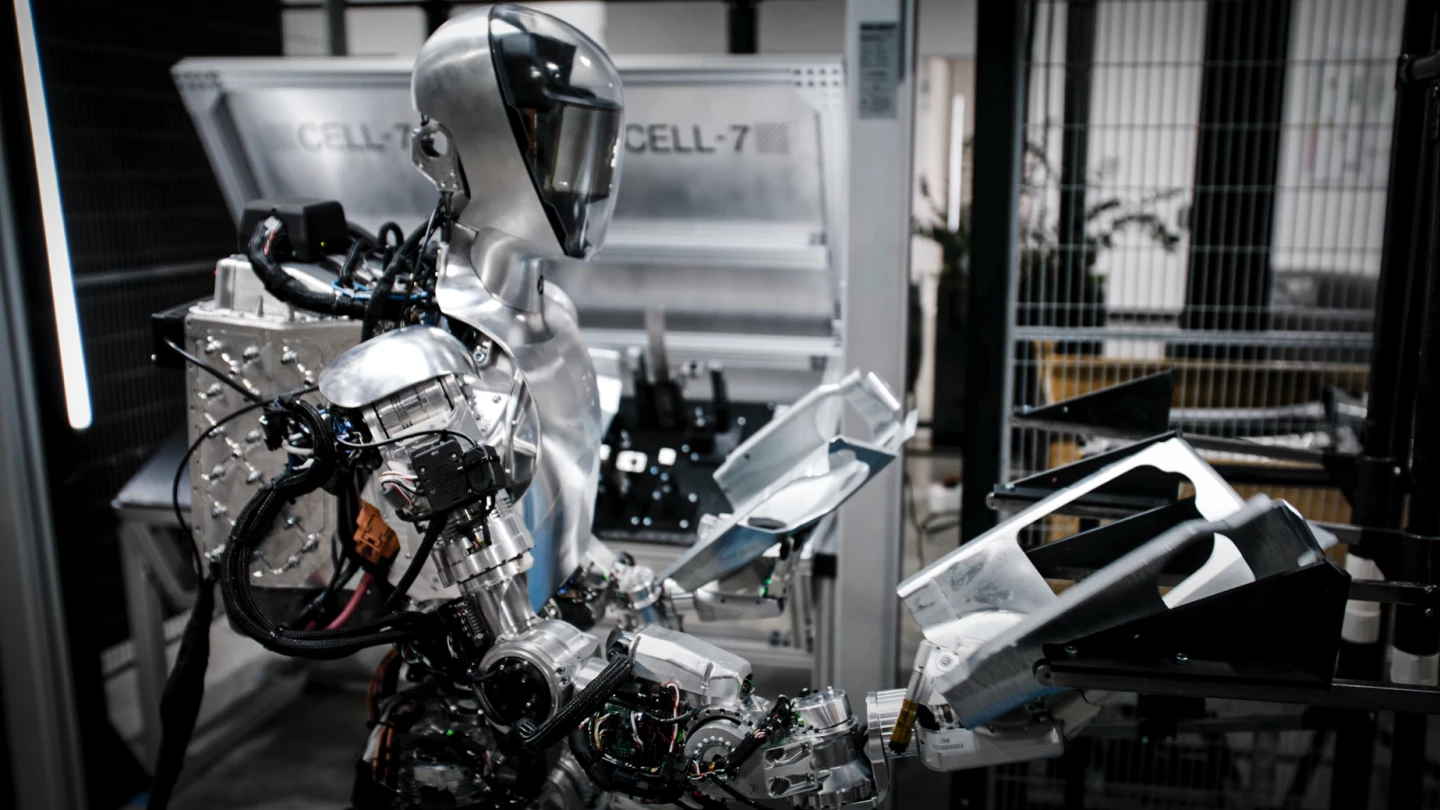

Picking up the two smaller pieces with one hand each is a little less impressive, as any human would do this two at a time. But it correctly identifies that it's got them the wrong way around, orients and aligns them with the jig, and pops them on the right way. And when it notices they're not sitting there properly, it taps them into place with the back of its hand, correcting its own errors.

On the other hand... Well, it's clearly being paid by the hour, not by the job, as one cheeky YouTube commenter points out. But to Figure's credit, the company clearly isn't speeding up its footage, and these kinds of motions will become faster and smoother with time.

This may not seem like a huge advance from the company's first real-world work task demonstration from February, shown above. Both could be categorized as "pick things up and put them down" type tasks, so this update does feel more evolutionary than revolutionary.

But the 01 is definitely picking up much more complex and interesting shapes now, requiring more intricate grips. And it's not just placing a box on a conveyor belt, it's lining up complex parts to place them in precision jigs.

While the video signs off with "BMW Group, Plant Spartanburg," it does seem like it's been shot in Figure's own building on a test rig. Assuming that's the case, we're not sure when the 01 is likely to begin seeing action on the BMW production floor.

It'll be fascinating to see how these robots perform in real-world work. They'll be slow and cumbersome and limited at first, but as their AI behavior models develop, both their motion and the pace of skill acquisition will accelerate.

But in order to take over the world, get manufactured by the million and start making huge society-wide changes, they'll need to prove a clear economic advantage over today's meat and bones workers. That's where things will start to get really interesting!

Source: Figure