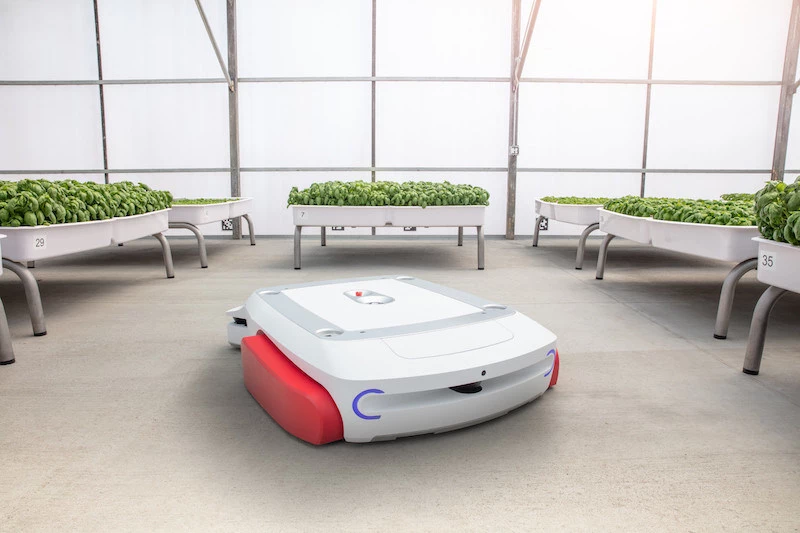

With large high-tech sustainable farming facilities located in Northern California and Texas, Silicon Valley-based startup Iron Ox relies heavily on robots to help shoulder the workload. The company's latest bot, named Grover, can lift over 1,000 lb (454 kg).

Not to be confused with NASA's polar exploration robot of the same name, Grover was designed in-house by Iron Ox's team of engineers.

The squat-bodied wheeled device features a unique type of rocker suspension, plus a differential drive system in which steering is managed by selectively actuating individual wheels. It autonomously makes its way around the greenhouse facilities via multiple LiDAR scanners, along with both upward- and forward-facing cameras.

The cameras also allow Grover to identify the 1,000-lb, 6 by 6-foot (1.8 m) hydroponically irrigated modules in which the various fruits and vegetables are grown. When the robot locates a target module – which sits propped up on four legs – it proceeds to precisely position itself underneath, then utilizes a motorized lift system to raise the module completely off the floor.

Grover then transports the module to a robotic scanning booth for automated inspection. If needed, the robot may subsequently carry it to other stations for additional watering, nutrient supplementation, or harvesting.

According to Iron Ox, implementation of the highly-efficient robot should allow the company to use less water, energy and land. The technology should also let the company promptly respond to market demand, as different crops can quickly be harvested – day or night – as needed.

Source: Iron Ox