There is an exciting branch of battery research that involves combining the strength and durability of next-generation materials with their energy storage potential. This could see car panels double as their batteries, for example, and in a new example of what this could look like scientists have developed a "power suit" for electric vehicles that could not only extend their range, but give them a handy boost in acceleration at the same time.

Sometimes known as structural batteries, we've seen some interesting recent advances in this space from research groups and even big-name automakers. Back in 2013, Volvo demonstrated carbon fiber body panels with energy storage potential, and we've seen other teams show off similar concepts since. These projects sought to combine the high energy density of batteries with the ultra-fast discharge rates of supercapacitors, in materials strong enough to serve as a car's exterior.

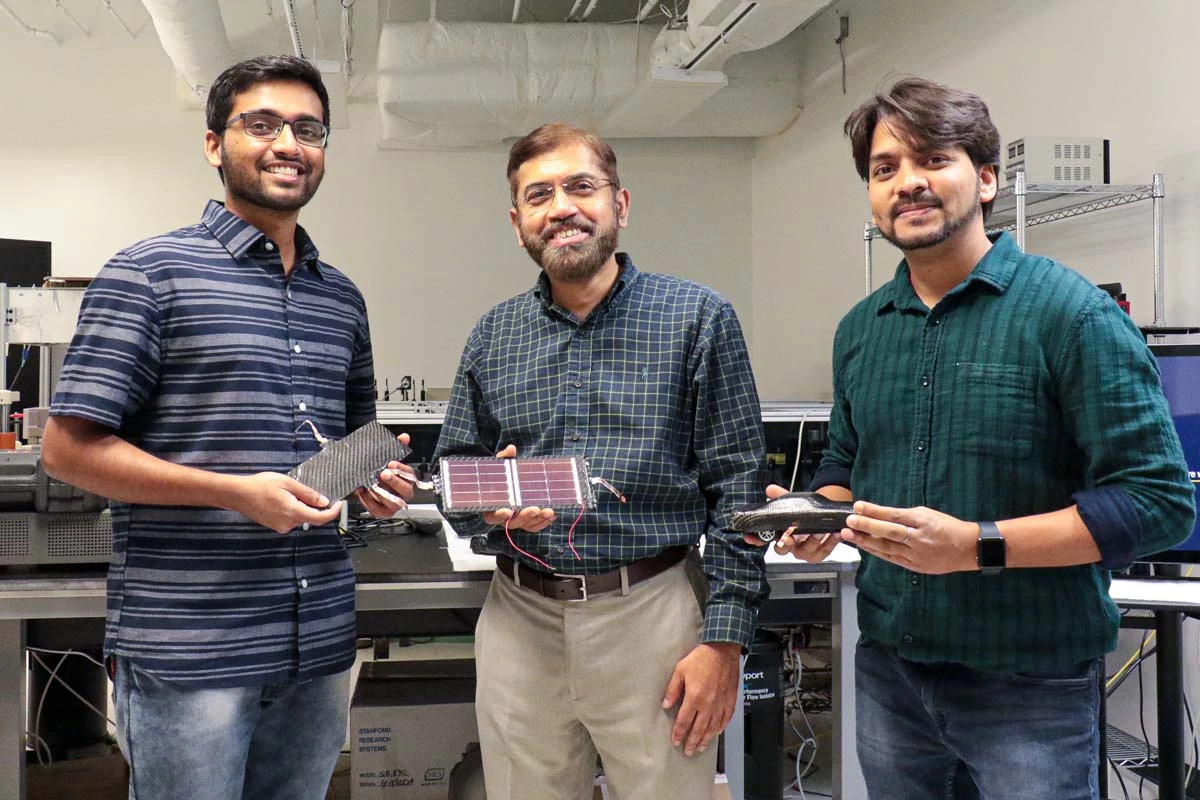

This new breakthrough continues this line of thinking, with scientists at University of Central Florida and NASA designing a new material featuring unique properties that allow for not just impressive energy storage potential, but also the strength needed to endure a car crash.

The scientists took positively and negatively charged layers of carbon fiber and stacked them together in an alternating pattern. Sheets of graphene were sandwiched between the layers to boost their energy storage ability, with the stacks attached to electrodes coated with metal oxides to increase both the voltage and energy density of the device.

This supercapacitor-battery hybrid device is as strong as steel, lighter than aluminum and boasts a bunch of desirable properties for electric vehicles. The scientists says that if used as typical car's body shell to supplement the battery, it could increase the range by as much as 25 percent, extending it from 200 miles (321 km) per charge to 250 miles (402 km), for example.

“Now in electric cars, the battery is 30 to 40 percent of the weight,” said study co-author Kowsik Sambath Kumar. “With this energy storing composite we can get additional mileage without increasing the battery weight, further it reduces the vehicle weight, while maintaining high tensile, bending and impact strength. Whenever you decrease that weight, you can increase the range, so this has huge applications in electric cars and aviation.”

Due to its supercacacitor-like capabilities, the device could also discharge power quickly to impact on acceleration, propelling an electric vehicle from zero to 60 mph (97 km/h) in three seconds. Further, the materials are all non-toxic and non-flammable, important for road safety, and the scientists say the charge-discharge cycle life is 10 times that of a typical electric car battery.

“This is a huge improvement over past approaches that have suffered from issues with toxic material, flammable organic electrolytes, low life cycles or poor performance,” said study co-author Jayan Thomas.

The scientists see the technology extending far beyond the world of electric vehicles, imagining it finding use in drones, portable devices, and wearable tech like futuristic eyewear or virtual reality headsets. One of the more immediate applications could be in space, with the team touting its potential as a material for satellite construction.

“Making a cubic satellite out of this composite will make the satellite light in weight and will help to eliminate the heavy battery pack,” said study author Deepak Pandey. “This could save thousands of dollars per launch. Further, free volume gained by removal of big batteries could help pack in more sensors and testing equipment, increasing the functionality of satellite. Supercapacitor-battery hybrid behavior is ideal for CubeSats since it can charge in minutes when a satellite orbits over the solar-lit side of the Earth."

The research was published in the journal Small.

Source: University of Central Florida