While this has been a very quiet year for airlines, about 2.5 percent of global greenhouse gas emissions generally come from the aviation sector, somewhere approaching a billion tons of CO2 per year. With air miles set to triple by 2050, this sector is a key target for decarbonization. Batteries are unlikely to displace fossil fuels in the powertrain; they can't carry enough energy per kilogram to deliver a commercially useful aircraft.

But hydrogen gas, running through a fuel cell, can already get you about half the range of an equivalent weight fossil fuel system, according to ZeroAvia's Val Miftakhov, and once liquid hydrogen systems make it to market, hydrogen aircraft stand an excellent chance of beating a tank of jet fuel on range. Hence, hydrogen is shaping up as a key technology for aviation, and many companies are working to make it happen.

We spoke to HyPoint last year about its next-gen "turbo air-cooled" fuel cell designs, which promised three times the power of a regular fuel cell by weight, as well as four times the lifespan, a much wider range of operating temperatures and the ability to run on cheaper "dirty" hydrogen that's only 99 percent pure, as compared to the 99.999 percent purity you'd require for a regular low-temperature proton exchange membrane fuel cell. In aviation, where every gram has to be lifted, weight reduction is a huge advantage, but a large reduction in maintenance and less finnicky fueling are certainly gravy on top.

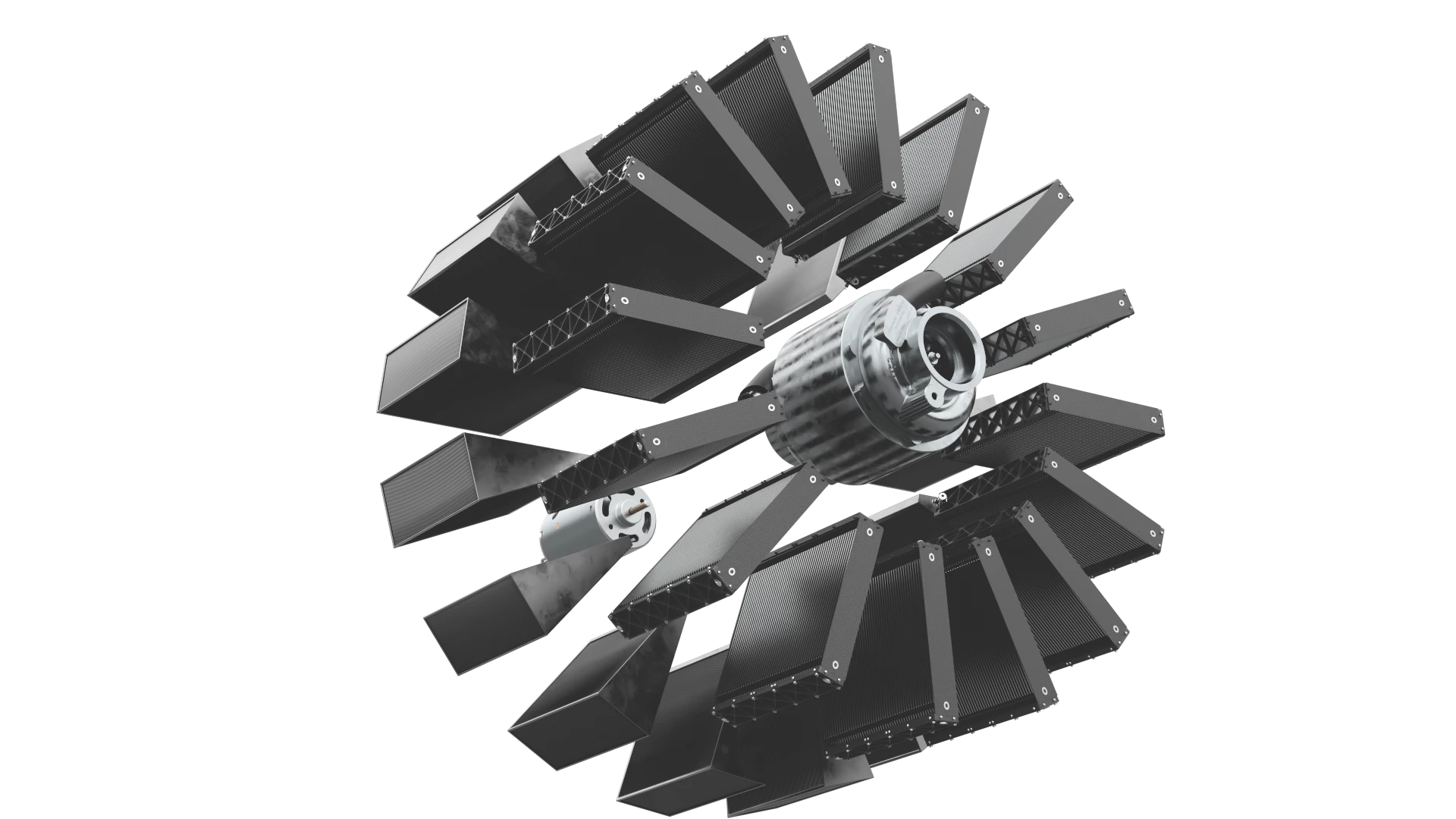

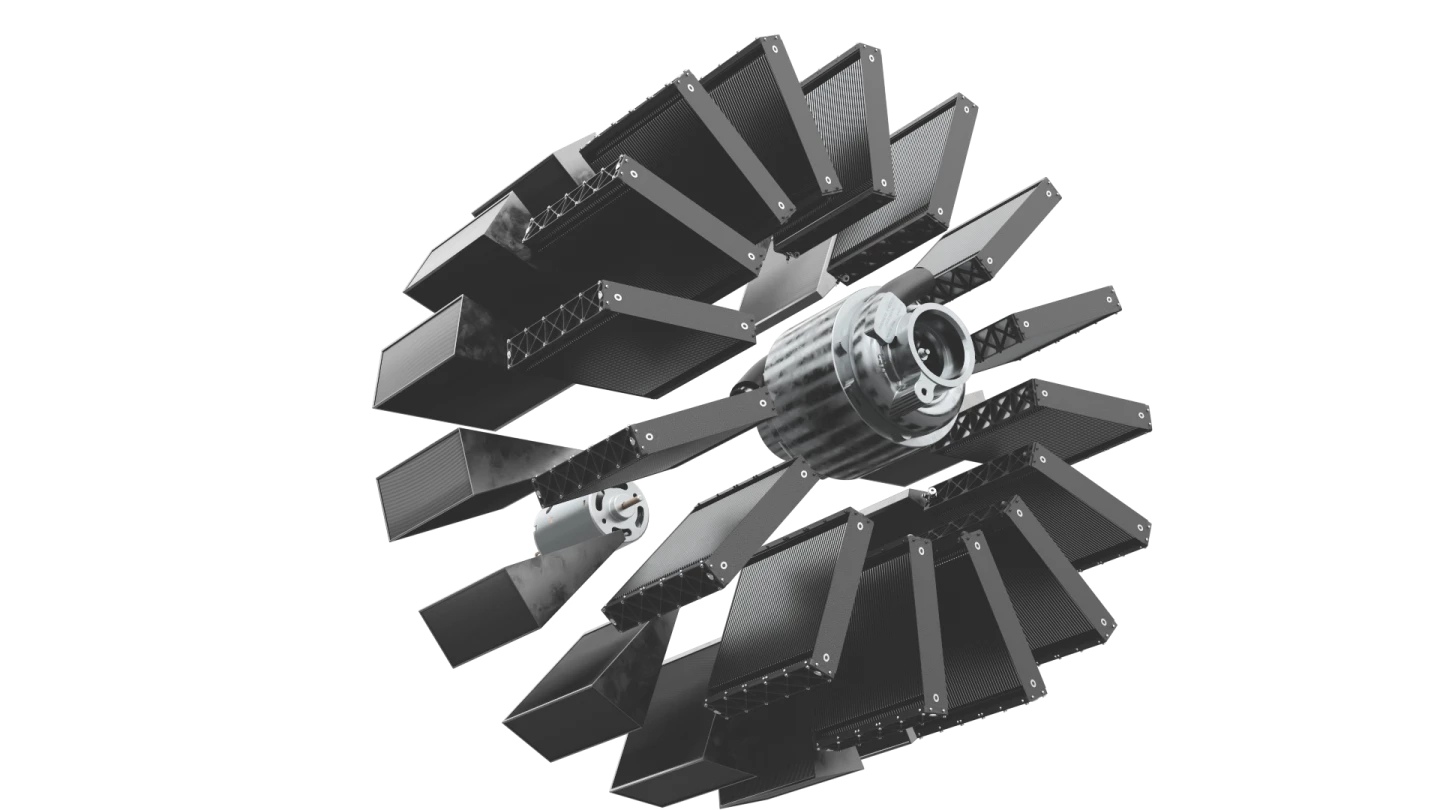

The HyPoint design is air-cooled, meaning it does away with plenty of weight generally tied up in a liquid cooling system. It runs a compression system that forces three times denser air through the cell than a regular air-cooled fuel cell by pressurizing the anode and cathode sides of the membrane with extra oxygen and hydrogen to complete the reaction. Unlike a low-temperature PEM system, it also doesn't need a heat exchanger or cooling liquid.

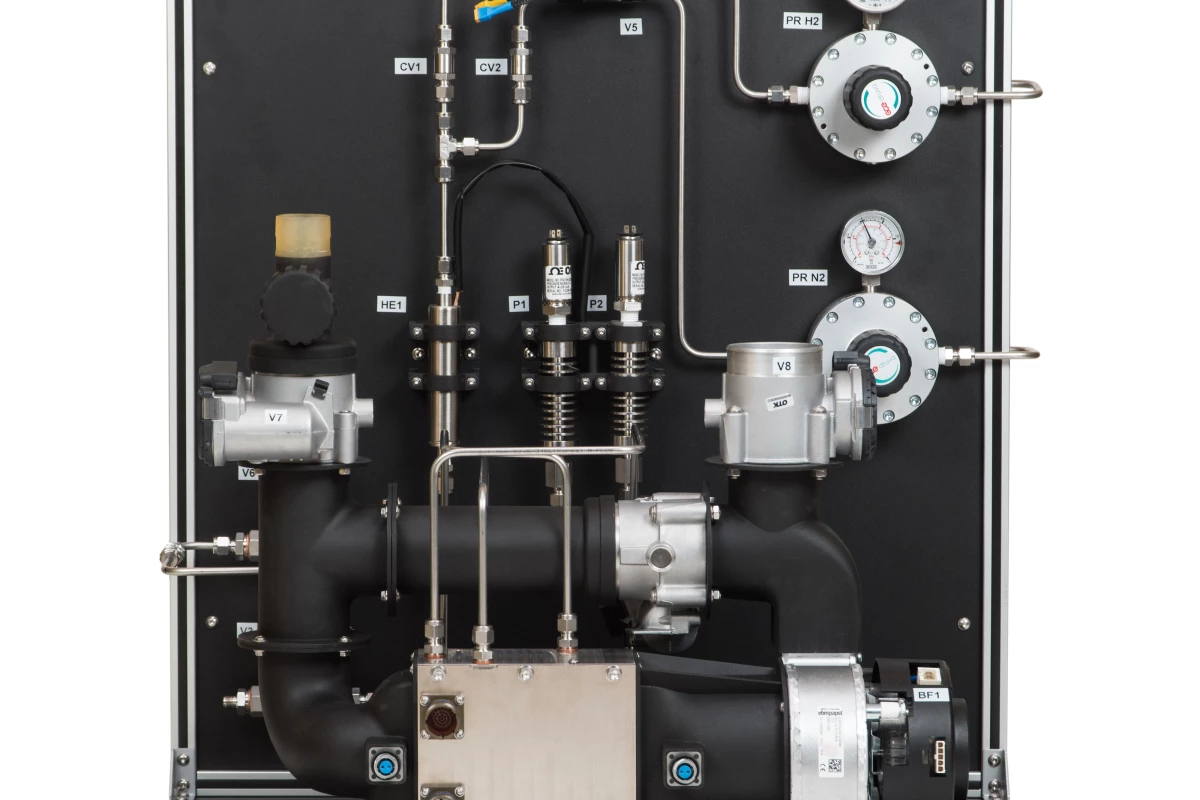

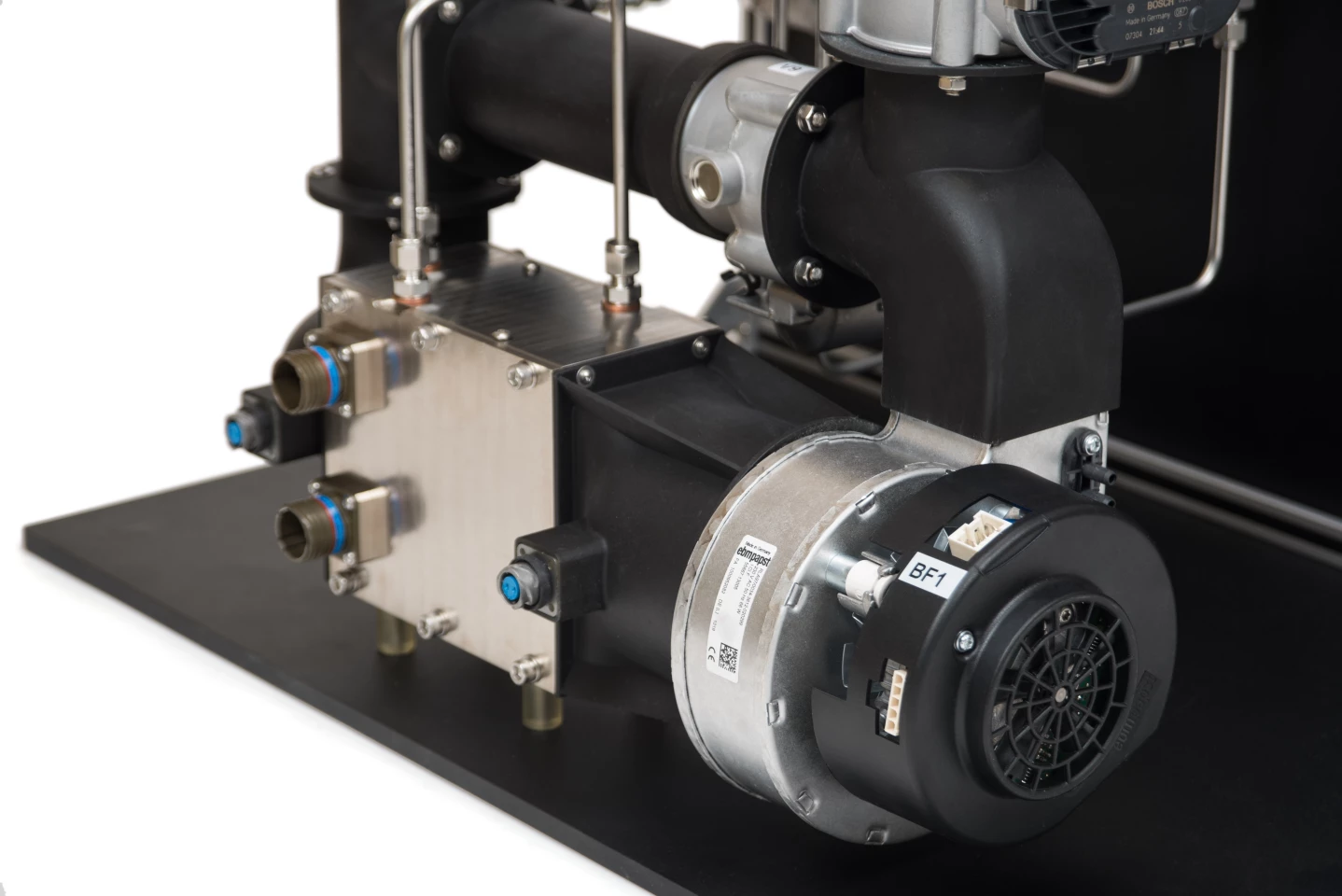

Now, HyPoint says it's got a prototype up and running to prove its claims. The prototype is a 400-watt lab validator comprising the fuel cell short stack, blower fan, recirculation loop, valves, pressure regulators, sensors and piping, packaged for experimentation not for compactness. It allows the team to imitate various weather conditions, and indeed full regional flight patterns for test scenarios. Despite parasitic power losses from the compressor, it's proving 40-50 percent efficient, which is not exceptional for fuel cells, but any lost range in efficiency is quickly recovered by the weight it saves.

"We built it in December of last year, as we promised to our investors and partners," says HyPoint CEO Alex Ivanenko over a video call. "It's a very crucial achievement for us because a lot of technological and fundamental validations are concentrated in the prototype. Last time we spoke with you, it was a single cell, and it was more about our theoretical modeling, etc. Now we received all necessary validations to build a full scale system."

The turbo fuel cell, says Ivanenko, will offer an additional advantage, particularly to eVTOL air taxi designers: it promises to make so much power that aircraft designers won't need to keep a battery or supercapacitor system on board as a buffer, where most existing fuel cell systems for eVTOLs are likely to act more like range extenders for small-to-medium-sized battery packs capable of meeting the high power demands of eVTOLs in vertical lift and hover situations.

In one eVTOL model HyPoint is working on, the entire energy system, complete with hydrogen tanks, will weigh 590 kg and be capable of delivering the full 450 kW (600 horsepower) power level required for takeoff. Such a system would give the aircraft a flight time around 118 minutes, with a total energy density nearly three times what a current Tesla Model 3 battery delivers.

"Our particularly high power density allows customers to exclude buffer batteries from the system design," says Ivanenko. "It means that the fuel cell becomes the main power source not only for cruise mode, but also for takeoff, landing, etc. This will make certification process with the FAA, for instance, much easier."

We're a little dubious on this point; the buffer batteries aren't just for supplying high power loads on takeoff and landing, but they also allow instant response of the electric motors when a gust of wind blows the VTOL off kilter and it needs to re-balance itself. So we ask Ivanenkov to clarify how quickly the turbo fuel cell can respond to load changes. He checks his engineering documents: "The time between standby and maximum power mode," he says, "shall not exceed five seconds."

I guess we'll see whether that's responsive enough to handle rapidly changing loads in an eVTOL application, but even if it doesn't completely eliminate the buffer, it'll definitely reduce its size and weight considerably. What the customer does with the weight savings, of course, is up to them; Ivanenko says there are opportunities for extra seats, extra cargo, or indeed extra fuel to increase range.

HyPoint currently has more than two million dollars worth of work in progress for two paying customers: ZeroAvia and the Piasecki Helicopter Corporation. "We can't disclose specific data on these projects, but we're definitely developing something interesting with them," says Ivanenko. "When the time is right, we'll make a revelation together. But we're not saying we're ready to go, we're already going. These prototype validations are part of our multi-step agreements with our existing customers."

A further US$50-60 million worth of work is awaiting final signoff, he tells us, starting around 2023 and contingent upon HyPoint getting a system into an aircraft certified by the FAA. HyPoint won't be directly responsible for certification; it'll be up to the customers as they certify their aircraft, but the company has brought a certification advisor aboard to liaise with regulators and make the process run more smoothly.

"2022 will be a crucial year for the aviation market," says Ivanenko. "Everybody expects to fly with different kinds of fuel cells in different aircraft in 2022-23. After that, I think it'll take half a year to a year for certification, and then commercial integration. Two to three years from now is my expectation. And in two years we'll have a full scale system, and we'll be the leader in that market. Our system can of course be integrated in cars, or heavy duty trucks, or marine applications. But for those markets, it's nice to have high specific power, but it's not crucial. In aviation, you must have high specific power. That's why we're focused specifically on that market."

The HyPoint team is currently working on a next level validation prototype. This will be a single module designed to fit into a multi-module arrangement for production. This year, it plans to begin building an initial manufacturing site with capability for between 2-10 megawatts per year. It'll be raising funds from various investors to take things to the next level.

"I think a lot of people are starting to believe in hydrogen, and that's really great," says Ivanenko. "If you want to solve the problem of climate change in aviation, hydrogen is the answer for energy storage. You can generate hydrogen from renewable energy; solar, wind, whatever, and deliver it to anywhere in the world." Indeed, airports may even be able to leverage their large surface areas to generate their own renewable energy, running hydrolyzers on site to contribute their own source of clean fuel.

It's a promising sector, and HyPoint may be in a great position to make a lasting contribution.

Source: HyPoint