Orlando startup JetX is planning a configurable eVTOL "flying car" chassis, and testing a quiet, modular propulsion system that vectors thrust from bladed or bladeless fans without tilting them, opening up some interesting design possibilities.

The idea of the propulsion vectoring system is to build propulsion units into the vehicle statically, then use one of a few different methods to take the airflow and thrust coming out of them, and vector it downward. JetX is testing with regular ducted fans, as well as fluidic propulsion units similar to the "bladeless fans on steroids" that Jetoptera is using.

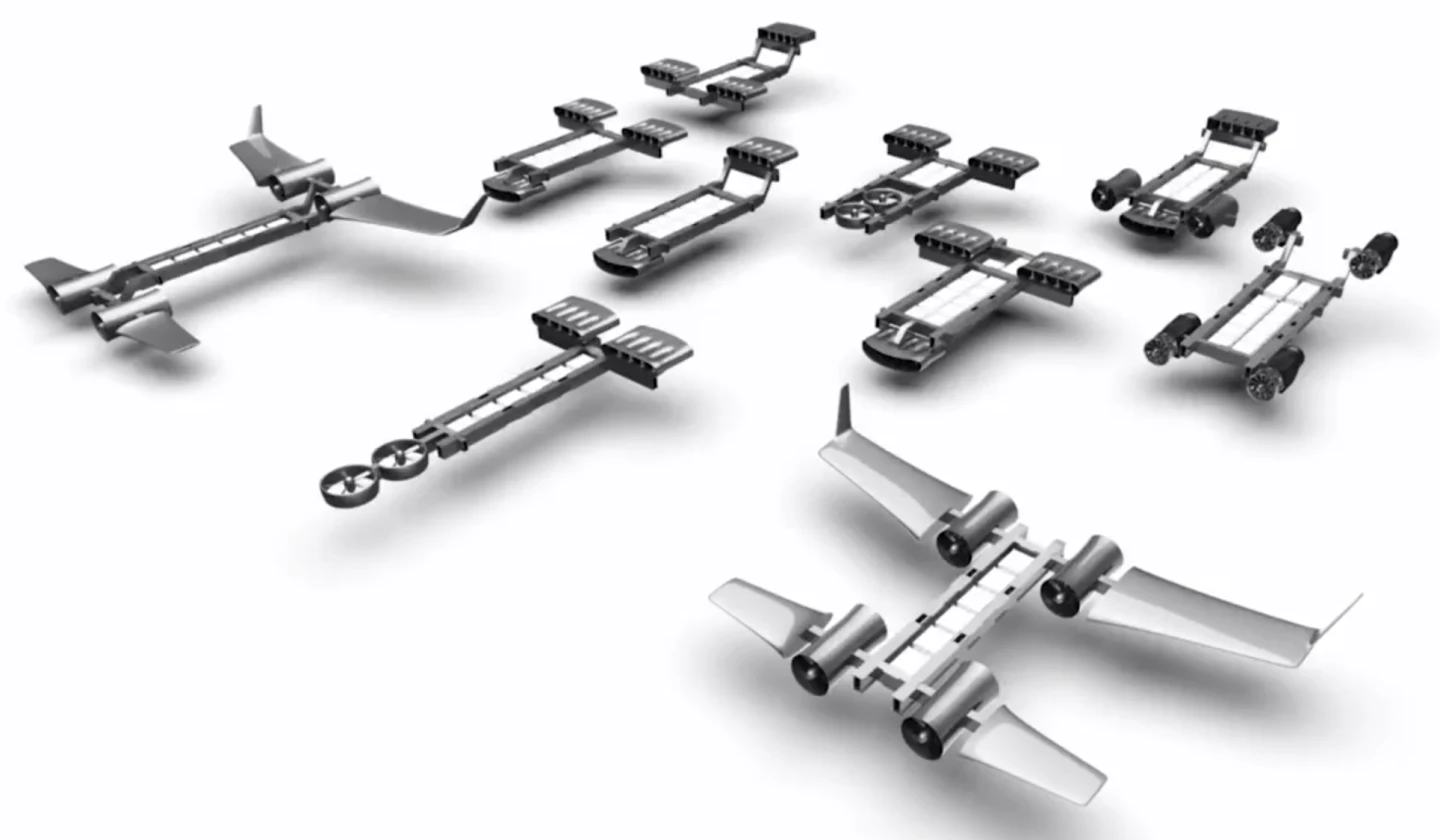

JetX doesn't seem to have settled on a particular method for vectoring the thrust. Indeed, it's designing and testing systems using ventral flaps, external flaps, "rotating" thrust vectoring, cascade vanes and buckets to do the job. Since the company plans to work with other aircraft designers, it's keeping options as broad as possible, largely independent of power sources or propulsion systems, other than to say they'll need to be relatively small-diameter fans to fit inside JetX's thrust vectoring system.

There are other aircraft that use thrust vectoring on a non-tilting propulsion system for VTOL purposes. The Lockheed Martin F-35B fighter jet is one example, although it does have the considerable benefit of a Pratt & Whitney F135 afterburning turbofan engine capable of pounding out some 40,000 lbf of thrust.

Closer to the JetX end of town might be the extended-range, nine-seat hybrid-electric eVTOL put forth by Odys Aviation. This design uses 16 medium-diameter propellers, mounted rigidly facing forward along a diamond box wing. There are flaps along the rear of each wing, which extend down to vector thrust somewhere between 75 and 85 degrees downward from the horizontal plane.

The question here, of course, is how much energy you throw away vectoring the thrust instead of simply tilting the propulsion units. Odys is unwilling to give any figures away just yet – when asked about the efficiency of the system, Odys co-founder James Dorris told us "of course it's not 100 percent. But it's high enough that this technology, given the reduction in complexity and the simplicity in transition, is well worth it."

The JetX solution looks very neat, and can be packaged in interesting ways on an airframe, but even without knowing exactly what fans it'll use or how it'll redirect the thrust, it looks to us like it'll be less efficient than the Odys design simply by virtue of the fact that you can't fit medium- or large-diameter fans into its propulsion enclosures. Smaller diameter fans, with their higher disc loading, tend to chew more power than larger ones for a given amount of thrust.

Still, it's an interesting idea, and one that can potentially be used productively in conjunction with other VTOL propulsion systems too, if the numbers come out high enough to make it worthwhile.

JetX isn't yet at the stage to be prototyping its own aircraft to prove the system; indeed, it's mainly concerned itself with prototyping and testing the vectoring systems up to this point. The company is hoping to work with other aircraft designers to bring the system to light, and it's looking into the idea of building a scalable, modular platform upon which any number of different aircraft could be designed.

Such a platform would expand to incorporate batteries, propulsion options, avionics and a flexible frame capable of supporting multiple different aircraft configurations. It would enable different designs to share pre-approved components, reducing the cost of certification in a manner somewhat similar to what REE is pioneering with its ultra-configurable flat chassis electric vehicle platforms.

Mind you, the certification costs for JetX itself could be absolutely epic, and anything like this will be a very long way down the track. The company is currently self-funded, although it was selected as one of the 36 companies AFWERX chose to participate in its High-Speed VTOL showcase. JetX has applied for a Small Business Innovation Research program through NASA, as well as the Leonardo accelerator program, and is now working to get up on its feet as a commercial entity.

"Until recently, most of our work in the last year was applying for patents," co-founder Bryan Welcel told eVTOL.com. "That was our main focus and took up most of our time. Our goal now is to seek funding."

Check out a short video below, showing some of the propulsion vectoring test rigs in action.

Source: JetX