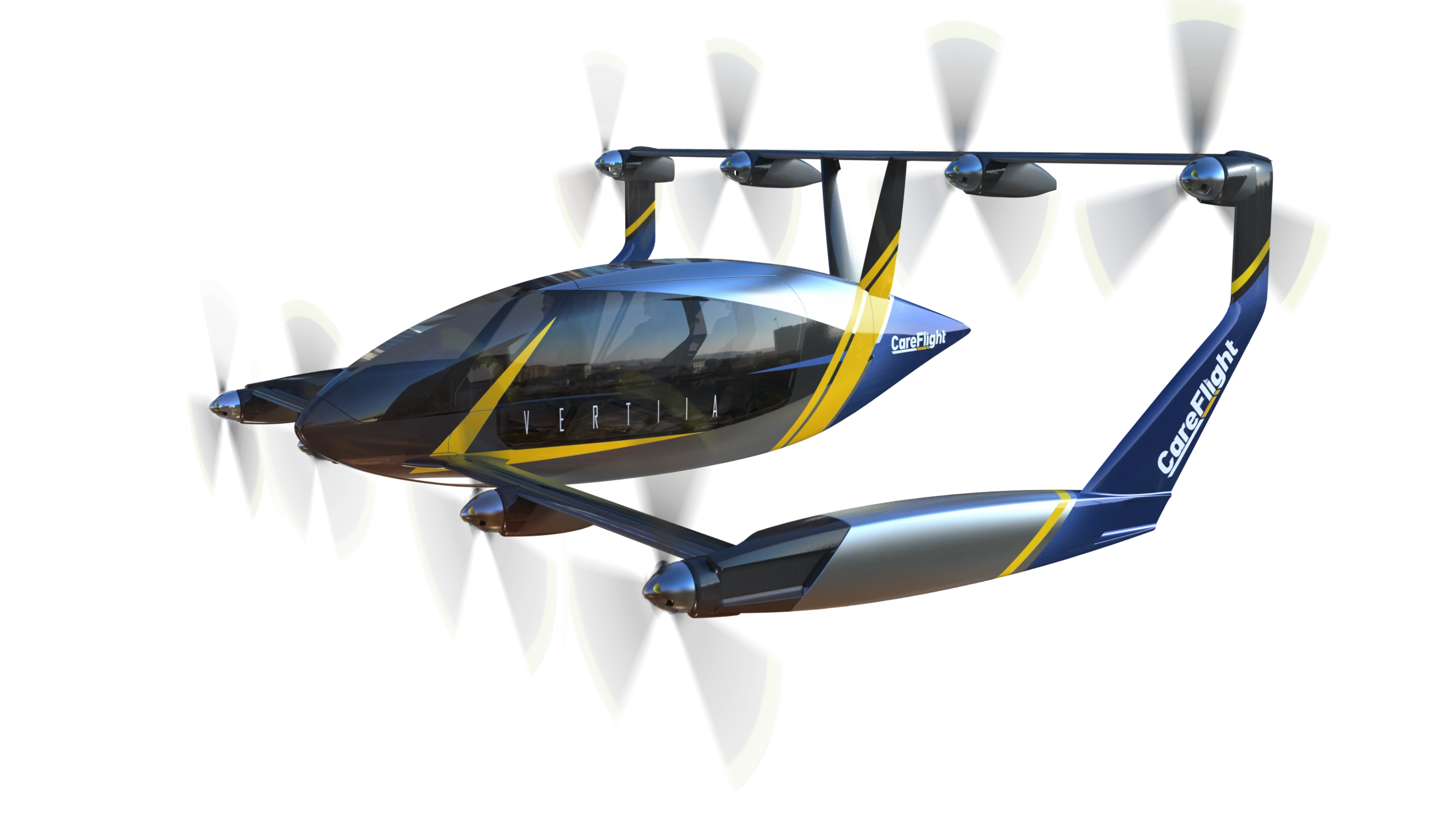

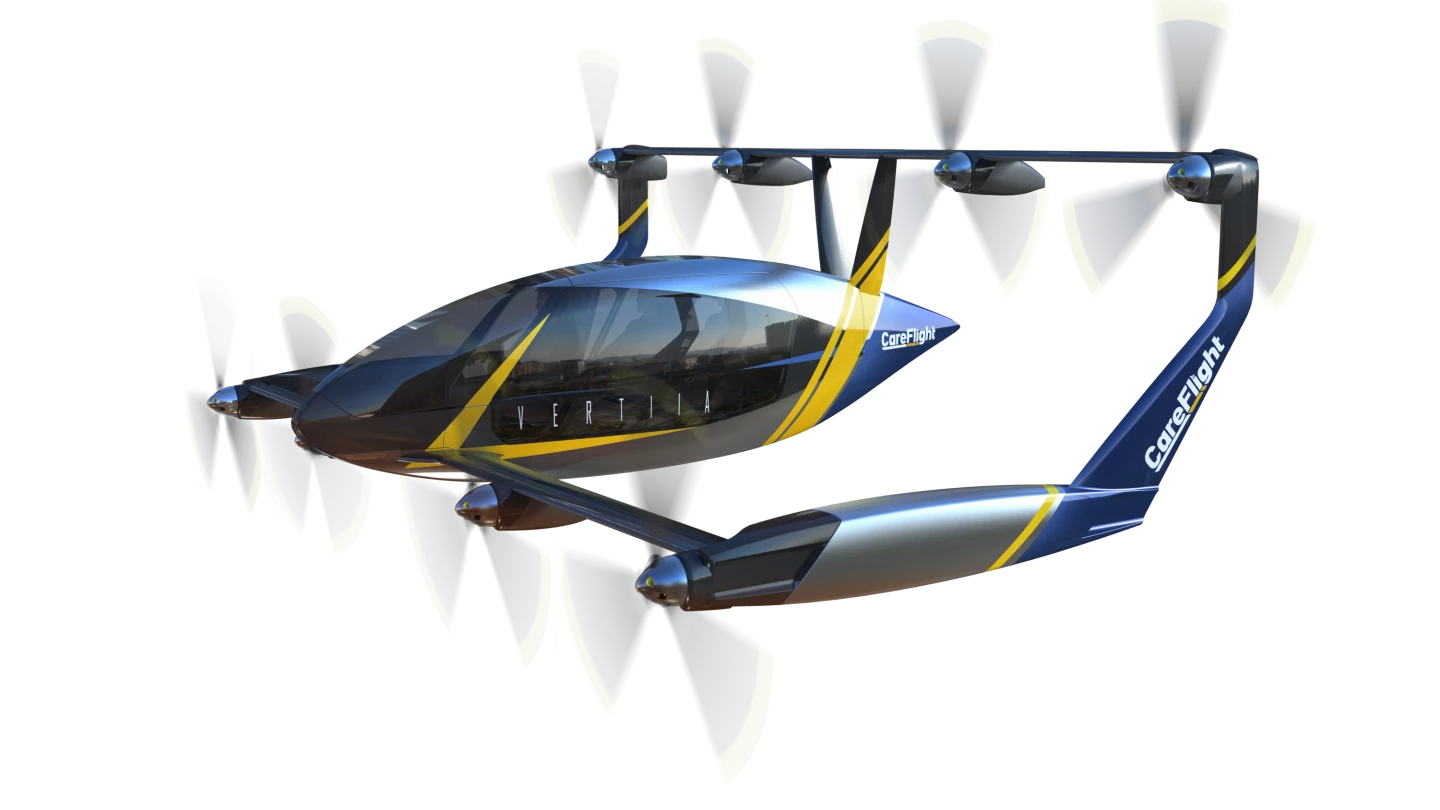

Australian company AMSL Aero is preparing to start flight tests on what it claims will be the world's most efficient eVTOL design, and one of the most affordable. This box-wing beauty, the Vertiia, will travel up to 1,000 km (620 miles) on a tank of hydrogen, carrying five people or 500 kg (1,100 lb) of cargo at a quick cruise speed of 300 km/h (186 mph).

First emerging from stealth mode late last year, AMSL has a unique design, a prototype nearly ready to fly, and a target date of 2024 to get its aircraft certified and into production. Its small team has achieved an impressive amount on a shoestring budget, and it's now raising another round of funding to finance flight testing and pre-production as it moves toward the certification process.

We spoke to co-founder Andrew Moore to learn more about this fascinating aircraft, and how Vertiia plans to stand out in a global emerging eVTOL air taxi market that's starting to look comically crowded. What follows is an edited transcript.

Loz: The design that you've chosen is, I guess, a vectored thrust box wing? You've got the wings that tilt with the props ... Well, it's not a tilt wing, but the the main blade surfaces tilt with the props. It's an interesting configuration.

Andrew Moore: Yeah, it's a hybrid between a tilt wing and a tilt rotor. It has the advantages of a tilt rotor in the sense that you've got a fixed structure, but it reduces the blockage and the waste by having a large, flat area that that tilts with the rotors. There's a number of good reasons for it, but essentially it makes it lighter and removes all the problems that tilt wings have with gust response and the "barn door" effect.

OK, is that just because this design puts a smaller area in front of a wind gust?

It does a lot of things. So first of all, the box wing's really aerodynamically efficient. That's why Lawrence Hargrave did all the box kites back in the day. And essentially a box wing allows you to have the same aerodynamic efficiency of a wing roughly twice the span. So we can achieve the same lift to drag ratios of an airplane with twice the wingspan, essentially. So that's the first thing the box wing does.

Second thing is, by having two small wings, the structure can be a lot lighter. So that's a good thing. The way that we've ended up, it gives us the ability to put energy storage in the wing tips, which further reduces our structural mass, because our wing doesn't need to, you know, sustain as high of bending load as it would if it was just a conventional wing with the batteries in close to the center.

Historically, though, box wings haven't become a common design. Why's that?

Historically, the main reason has been some issues with flutter. Flutter, on a traditional airplane, is sort of a combination of the wing going up and down and the wing twisting. And there's a speed where they both couple, and the flutter speed is where the wing rips off and the airplane crashes.

I can see how that could be viewed as a disadvantage.

Yes! So for a box wing, it's a very different shape and different scenario. If it just has a single tail, it has what's known as a T-tail flow, and you get this weird coupling motion. So being somebody who's studied this configuration for a long time, and coming from a helicopter engineering background, where we deal with flutter all the time, we design the blades so they just don't flutter, even though they're very flexible.

So we've essentially dealt with it through a combination of mass distribution, and in the geometry of our tail, and those things, essentially, give us a flutter speed that is really, really high. That's all in analysis – we haven't yet tested it for real, but using the tools that everybody uses to test out and evaluate the flutter speed, we essentially can stay clear of flutter up to 500 km/h [310 mph] quite happily.

Right, so how fast will you realistically be flying?

We designed it to cruise at 300 km/h [186 mph], but yeah, it's just a matter of bit more energy and a bit more power and a bit more altitude and we could go a lot faster.

Yeah, right. What are your target range and speed and passenger figures at the moment? One pilot, four passengers?

Yep, or one pilot, one medic, one patient for an air ambulance. As far as range, we're working with batteries off the shelf, 220 Wh/kg sort of cylinders. They'll give us around a 250 kilometer [155 mile) range. But what we're really looking to do is hydrogen, and hydrogen fuel cells. And because of our combination of efficiency and a few other things, some of the off-the-shelf hydrogen fuel cells enable us to push that out to about 1,000 km [620 miles] for the same mass as the battery.

That's enormous. And that'll be very handy in a place like Australia with so many remote towns and areas to get to. So hydrogen powertrains, what stage are they at to your knowledge?

There are a number of companies making fuel cells for different applications, primarily focused at the heavy trucks and automotive. There are fuel cells out there in the ecosystem that make just under a kilowatt per kilo. You've spoken to HyPoint, you might've heard of PowerCell, you might've heard of Hyzon, you might've heard of Intelligent Energy. So there are several companies who are working on fuel cell systems, which will push above one kilowatt per kilo. And based on our analysis, we found that for our aircraft, a hydrogen fuel cell system becomes viable at about 0.6 to 0.7 kilowatts per kilo.

Someone's got to certify one, before anyone can really start using it, yeah?

Yeah. Look, there's a certification program underway right now. Having gone through the cert requirements, the only unique part that hasn't got a history is the actual fuel cell stack. But if you do the right architecture, then you can really reduce the risk of that becoming an issue. And given that fuel cell stacks are very reliable, it's not like a piston engine with lots of moving parts, it's relatively straightforward to do the durability tests that you need to do on that to prove that it's safe.

Right. Would you be running the fuel cells straight, or as a range extender with a buffer battery?

So we've done all those studies. There are lots of great things happening with hydrogen fuel cells, which would allow it to be just purely hydrogen fuel cells. But right now it works and makes perfect sense to have a buffer battery and the fuel cell. A transitioning VTOL suits that particularly well, because you can have a relatively small buffer battery for takeoff, and then cruise on the fuel cell.

Will the fuel cells be out at the wing tips there, or will you keep those on board?

There are a few options. Our plan is to have the tanks out at the wingtips. The prototypes we've been designing have the fuel cells out at the wingtips as well. There's some complex packaging. There are some bulky parts in the cooling system that we're still working through. There's a level of flexibility, we could put the stacks themselves elsewhere if we needed to.

Okay. People still have safety concerns around hydrogen. I don't really know that they're all that valid. But how do you address that in your design?

Well look, for any energy storage system, you've got to pass a few tests. They include drop tests. They include general hazard assessment and those sorts of things. Putting the hydrogen on the wingtips goes a long way to dealing with those, because a major concern is about fire in the cabin of an aircraft. If you can keep the hydrogen away from the passenger cabin and in an arrangement where it's directly vented to the atmosphere, you can mitigate pretty much all those problems.

And we know of people who've dropped hydrogen tanks, carbon fiber tanks, in an attempt to see what happens and have dropped them from really ridiculous heights, and they bounce really, really well. So you're more at risk of dying from a hydrogen tank being dropped on you and bouncing away from a drop test, than you are from it actually causing the problem.

ZeroAvia managed to accidentally crash a test plane as well. And again, no issues with the tanks there.

If you go back and look at helicopter history, for a long time, helicopters had horrendous problems with liquid fuel, and those tanks rupturing during a crash or after a crash, leading to catastrophic fire. So, hydrogen's actually better than that, because it doesn't pool, it doesn't flow around the cabin and those sorts of things.

So that combination of putting it at the wing tips, and a gas which escapes upwards, actually can make it safer. And for those of us who have worked around aircraft for a long time, we know people who who've worked sealing diesel fuel tanks and all those sorts of things. And the health effects ... Many of the older guys that I used to work with ended up with all sorts of horrible cancers and things, purely because they're working around aircraft fuel tanks.

It's not often written about, but it's certainly something worth considering. I've managed to end up with fuel all over myself a few times in the past, and it's not particularly pleasant. So removing that is a big positive in my eyes.

Right. So I guess we're, what, nine months out from the launch? Can you bring us up to speed on what you guys have been up to since then?

Yeah, so we've been dealing with COVID lockdowns. We're in the final stages of integration for our aircraft, held up at the moment by COVID. Between several different lockdowns, and a little bit of nervousness in between, we're waiting for this latest one to finish so that we can finalize that last piece of integration.

When you say integration, you're actually getting the powertrain in there and getting ready to fly?

The powertrain's in there. This is the autopilot. So we've been working with a few companies, but because of COVID we actually have chosen to develop an auto pilot in Australia with a local company, but they're Melbourne-based. So right now with COVID travel restrictions, it has been more complicated than normal.

What's your timeline looking like for flight testing?

Once lockdowns are over, there are several activities we will be able to complete in preparation for our flight test program. Assuming COVID travel restrictions ease soon, we are targeting early next year.

Is the autopilot part of the flight controller or is that separate?

Yeah, it is. Technically it's a digital flight control system.

Okay. So you're not going with something off the rack from Honeywell, for example?

We have been working closely with both a UK and Australian company for this stage of development.

Right, right. I mean, my understanding was that as far as the certification process goes, it actually ends up being cheaper, sharing certification costs between partners. But this is such an expensive game to get into. I guess, as the lead company working on this stuff in Australia, it's up to you guys to set the agenda with CASA. How's that process going?

We've been engaged with CASA essentially since the company started and we talk to them regularly. We've had a pretty good relationship with them over the timeframe. So clearly, we're working with them to allow us to commence our test flying. At the high level, we've agreed on the general approach for our certification program and plan to kick that off shortly after our next fundraising round.

Right. So a CASA certification will be valid in Australia, are you looking to certify internationally as well?

Yes, CASA has a bilateral agreement in place with the United States in which United States recognizes a certification CASA does. But there are limits to that. Essentially, what CASA will propose is a joint certification with them and the FAA. CASA's recognizing we're electing to use the FAA Part 23 standards. It accounts for the fact that the FAA is the most experienced in this globally, and allows CASA to learn those lessons in a relatively quick way.

OK. So globally, there are hundreds of companies in this space now, all competing for funding and pre-sales. How do you see Vertiia fitting in? Where are the key advantages for the for this design? Where can you guys shine?

Well, because we design for Australia, where distances are farther, we start out from the outset designing it to be extremely efficient. So our prototype, which is not that different from what our product would be in size and mass, we expect will be about 1,000 pounds [450+ kg] lighter than what we see as the leader. So that's good.

That'd be Joby?

That'd be Joby, yeah. Therefore we use less energy to do the same job. So we see ourselves winding up being the lowest total cost of ownership. Combine that with hydrogen, and we'll end up in a space where we're able to travel four times the distance.

If you look at total cost of ownership from hydrogen, then it further improves that operating cost advantage. Because in battery aircraft, the batteries need to be replaced annually. You get a hydrogen fuel cell stack, it's got a 20,000 hour life, so you won't have to replace it for the entire life of the aircraft. And it's the same with the tanks and all of the major parts.

So we've focused on trying to make the world's most efficient VTOL. And today, we're on track, we're certainly the lightest for the same payload and cabin volume. We've got a small footprint because our box wing allows a shorter wingspan. All of those things will add up to greater flexibility and a lower operating cost. We believe that in this business, cost will win. And we aim to be the most cost-competitive from that standpoint.

Okay. So the weight advantage comes from the lack of a big wing structure that needs to support tilting propulsion pods? The extra structural stability from the box wing lets you remove a lot of material?

Yeah, absolutely. It means we can have a lighter wing structure. The aerodynamic advantages of the box wing include a lower induced drag. And that's a known thing, there are papers from the 1920s that described it initially. And of course, with a lighter structure, you can use lighter propulsion, and it all cascades – you can get away with a lighter battery, etc, etc.

The motors on your prototype look absolutely tiny.

Yeah, well, they're an off the shelf motor, a variant of it has been used on aircraft for quite some time. So it's quite low risk from that standpoint. We don't have to design a new motor. A lot of our competitors need a bespoke motor. So those things are good for us, they reduce our risk. And there's another upside there, we're tracking very closely with what's happening on electric motor developments, as well.

Yeah. Cool. So you've just got a bit of cash in through Sydney Uni?

Not quite. There's an Australian government grant, cooperative research center projects. And so we're actually on two grants. We were the leader for one, and the University of Sydney is one of our partners on that. And we're a partner on the second, which is all about increasing the volume density of hydrogen storage.

Right, and this will be gaseous hydrogen?

Yeah, it's using metal organic frameworks, which increase the amount of hydrogen you can store in a gaseous container. We've been advised up to three times the amount of hydrogen stored in a gaseous cylinder. That'll allow us to use a smaller gas tank, essentially. If they work as well as the researchers think, then they'll be very useful in storage across a range of industries.

Cool. All right. So next step for you guys is to is to get your prototype assembled once you get access to the parts, get it test flying ... What does your timeline look like from there?

We're raising capital now. That'll allow us to continue our flight test program, and to start building pre-production and developing pre-production aircraft.

Essentially, we've got the prototype in the hangar, we've also got a cabin prototype as well, which we think will be very close to the finished aircraft cabin size. We've already shown it off to several potential customers who are quite keen. We've also had two contracts with the Australian Army through the Defense Innovation Hub. They're interested in us providing a cargo aircraft and a medical evacuation aircraft.

What's the size of the company at the moment?

It's about 15 people. My background as an Aerospace Engineer is in designing and building helicopters, and in business development with a defense company. Siobhan spent 11 years with Google, where she was a People Operations Director for Asia Pacific. We founded the company together in 2017.

I was amazed to see that you guys got the prototype to the point where you had by last November. I was completely unaware of the project.

Yeah, we only received basically three and a half million dollars of investment, and we've built a prototype airplane. We did get a defense contract, and we did get a grant or two along the way, but we've done a lot with a little bit of money.

Absolutely. And you've got the hookup with Careflight, they're interested in taking some of these things on board for for medevac operations. What else do you plan to do with them? Are you going to run your own service? Or are you going to sell to service providers?

Right now we're focused on on building the most efficient aircraft. There are lots of additional steps if we wanted to operate them. And there's also some potential anti-competitive laws that we need to be careful of. So we really think that we'll build it and sell it.

As for use cases, there's an air ambulance or patient transport application. We've designed it for the four-passenger, five-seat configuration, so it'll fit the air taxi use case quite well. There are people who want to carry cargo; we can take up to 500 kilos worth of cargo, which is quite good. And then we've got these defense opportunities; defense are really keen to have an air ambulance, and to move cargo as well.

Careflight sees great opportunity in Vertiia’s ability to transport patients, particularly in regional, rural and remote Australia. Today, people use lots of airplanes for patient transport, often moving patients from hospital to hospital. Because it's so expensive to do that with a helicopter, they use an airplane, and they have to transport the patient from the hospital to the airport, fly to the next city airport, put them in another ambulance and then take them to the next hospital. This sort of eVTOL aircraft could do direct hospital-to-hospital in probably half the time, and reduce a lot of the movement transferring patients from road ambulance to air ambulance, those sorts of things. So it's not just Careflight, other operators and other air ambulance services are very interested in how our aircraft can provide improved health outcomes while also providing a lower cost transport option.

But then it can also be used for those emergency response tasks where they fly one of these out and pick somebody up from the middle of the bush or something like that. The flying doctor service, half of their missions, they fly to an airstrip, and then spend another half-hour to an hour driving to wherever the the sick person is. So something like this, of course, can go direct to their door and make that process so much simpler.

Will they be allowed to land in people's backyards? Or, you know, on people's properties?

Yeah. Not an issue. With a helicopter today, as long as you have permission from the land holder, and as long as it's clear enough and a certain distance from buildings, then you can land on the place. So yeah, it opens up some new opportunities there. There's so much of Australia where there's lots of open space to land these things. So really the challenge is making sure it's a low enough cost to operate that makes it viable.

That could change things radically, you can live on your dream farm down by the water, have a bit of space. And you could just paint a little circle with a V on it, and an eVTOL could pick you up from home. There's a real opportunity here to make these things accessible to the average person.

But really what we're trying to do is make the fastest door-to-door transport up to 1,000 km. So if you wanted to fly from Melbourne to Sydney, then of course you'd have to drive to the airport, there's about 40 minutes, then wait 30-60 minutes at the airport, then take your hour and a half flight, and then go through all the ground transport rigmarole at the other end. With a hydrogen-powered eVTOL, we can probably save you two hours on that trip.

Awesome. Well, thank you so much for making time to catch up. I really appreciate it. And yeah, looking forward to watching your progress, as we get towards the fun stuff where you're actually up in the air and doing the Wright Brothers thing.

Thanks to Andrew Moore and Siobhan Lyndon for their time on this story.

Source: AMSL Aero Vertiia