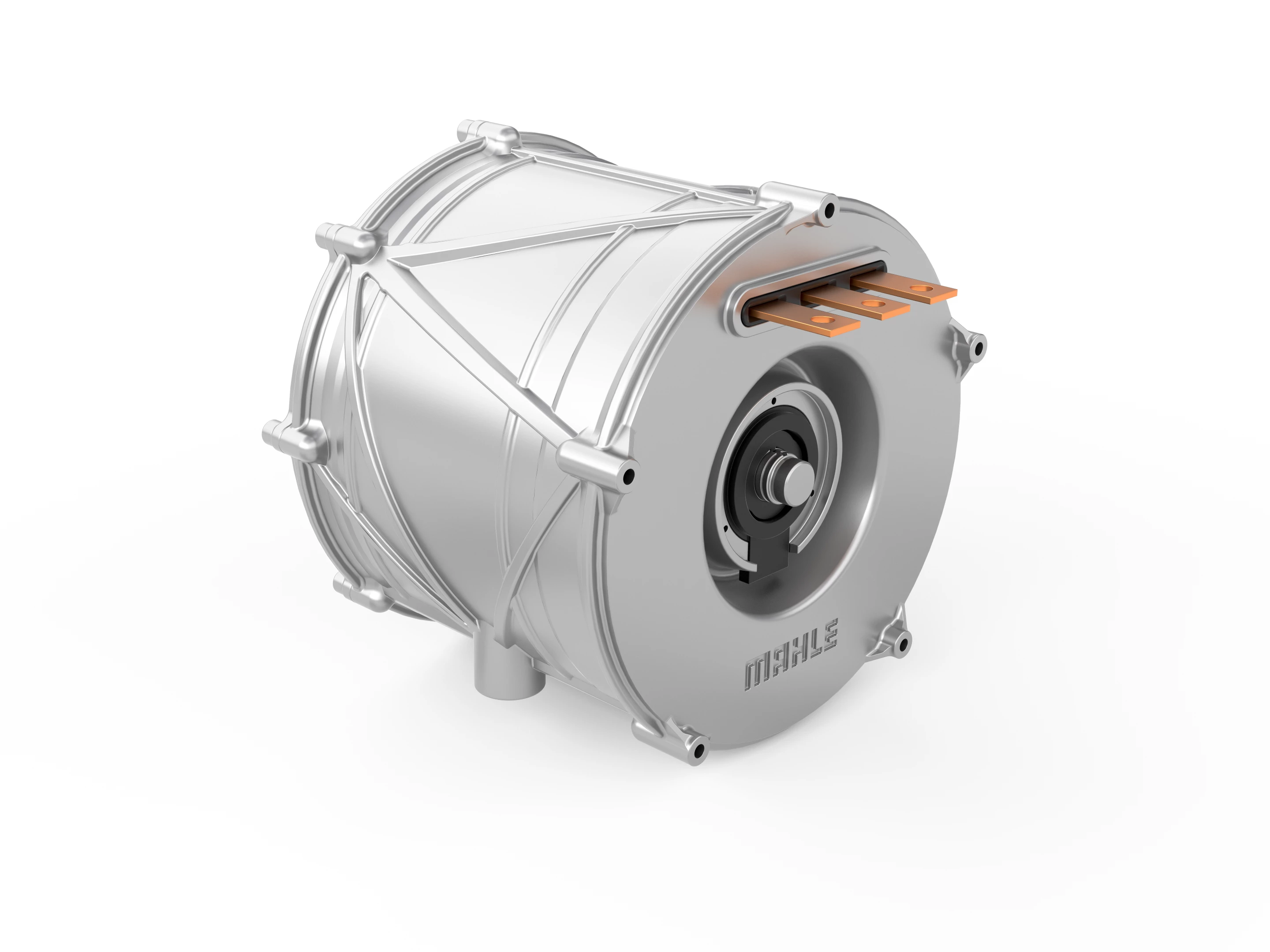

Back at the IAA Transportation 2022 exhibition, German Tier 1 automotive supplier Mahle presented the Super Continuous Torque (SCT) motor, an electric machine capable of running continuously at 90% of its peak power. It was an impressive little workhorse, and this year, Mahle further refined it into a full drive unit, integrating two SCT motors and a cooling system into an all-electric truck axle with claimed 92% continuous power output and near-700-hp peak rating. The working axle essentially does more with less, using small motors for demanding tasks.

When it first revealed the SCT motor two years ago, Mahle detailed how the integrated oil cooling system enabled it to continuously dissipate heat and run at a high load of 90% peak for unlimited periods of time. Typically, motors have less efficient cooling and must run at a lower continuous power to prevent overheating and damage, resulting in a larger gap between continuous and peak power ratings.

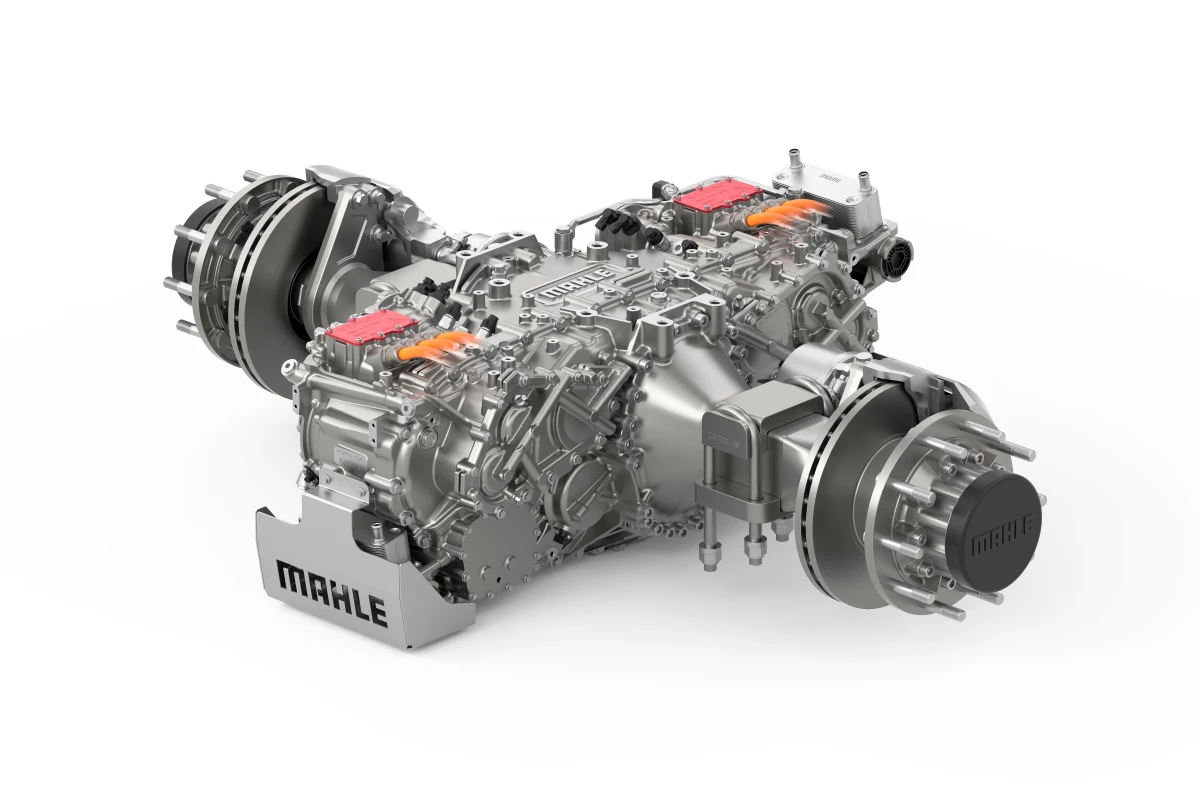

The SCT was always designed to power a range of battery- and fuel-cell-electric vehicles, from light passenger cars to heavy-duty trucks and machinery. Mahle caps its new working electric axle with an SCT motor at each end to show how effective the small, efficient unit can be. With an oil cooling system integrated neatly within the axle, the two motors combine for a peak power of 697 hp (520 kW) and a continuous power of 644 hp (480 kW), further improving upon the original 90% figure with a continuous output of 92% of peak.

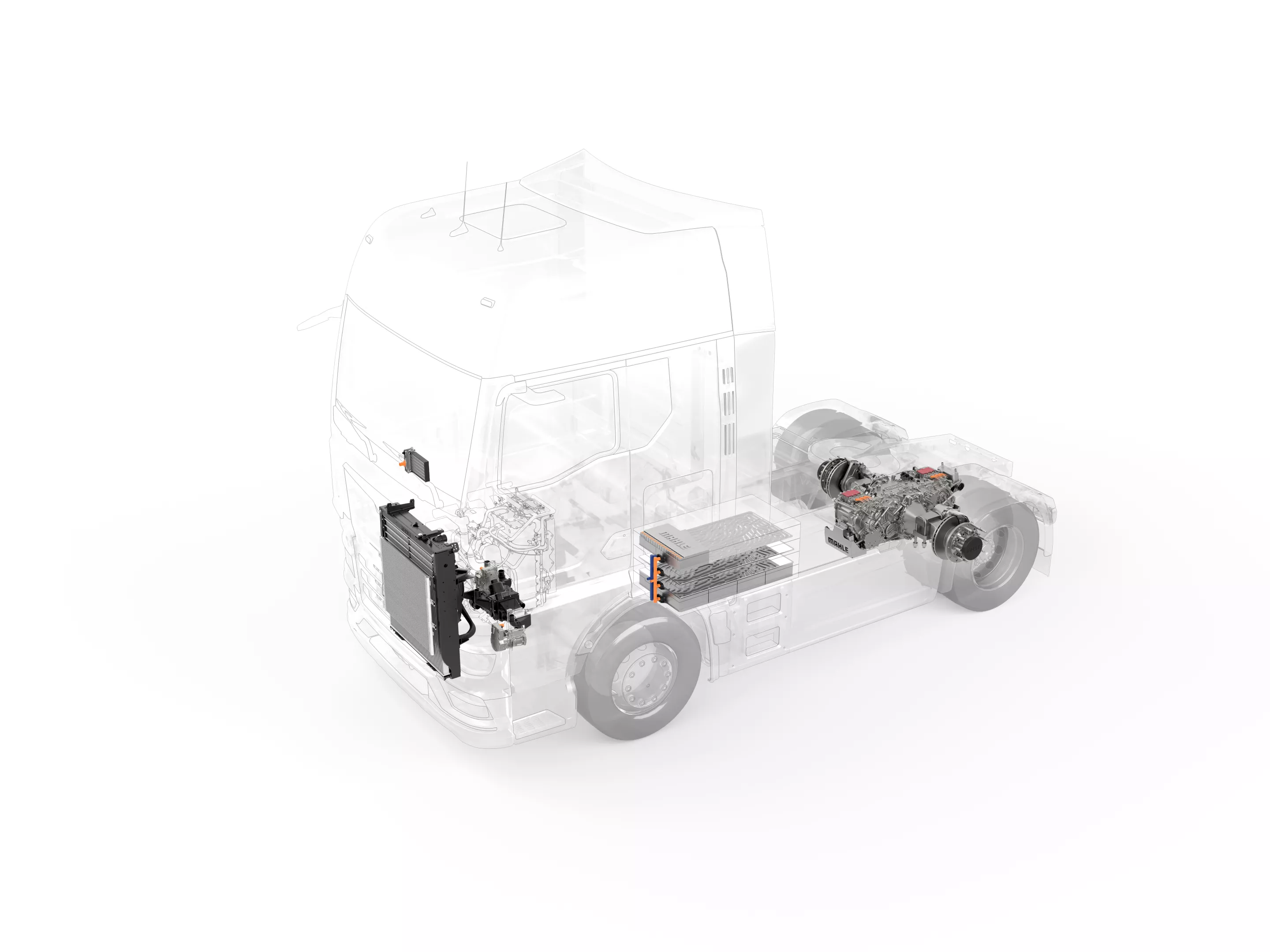

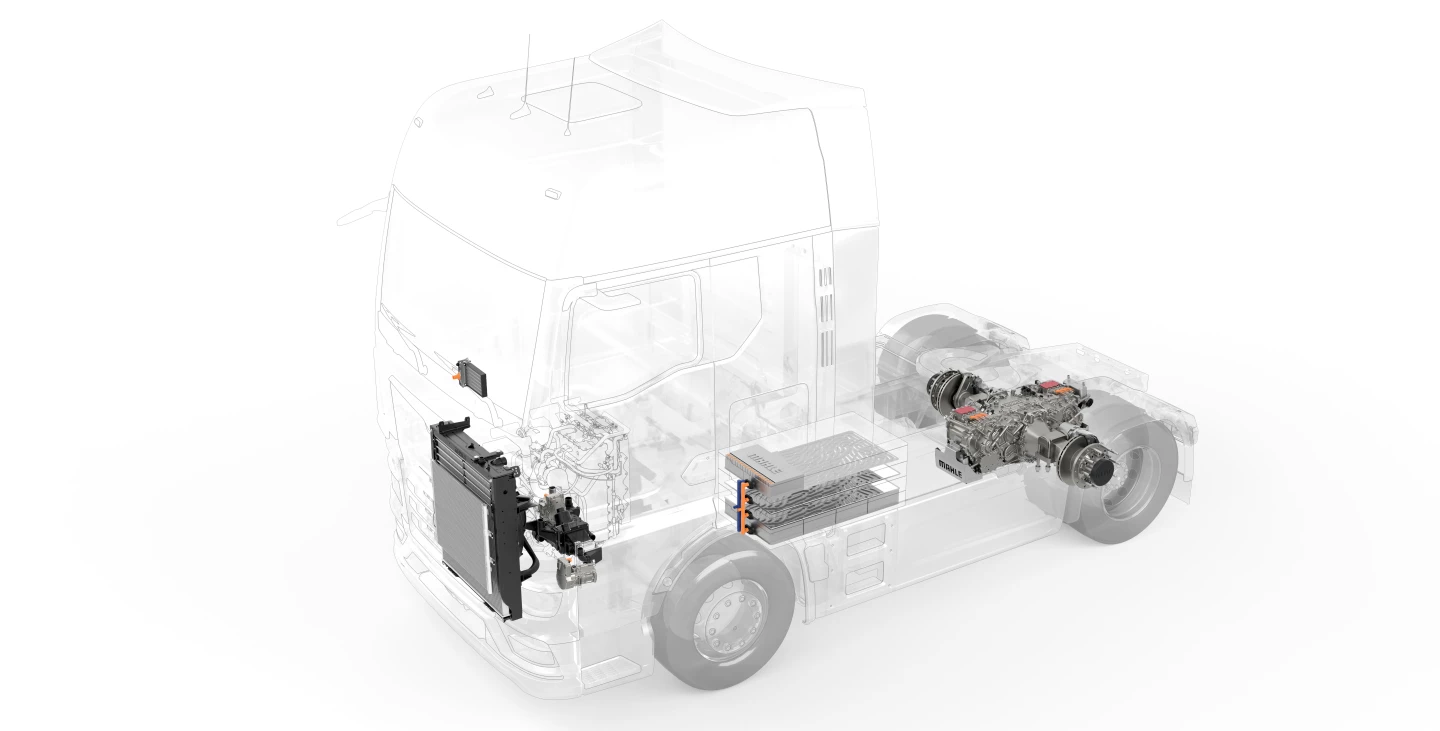

It's not hard to imagine why more power for longer is desirable, and Mahle has used the example of a heavy-duty fuel-cell truck cab to emphasize its utility. The steady high output at the rear wheels could allow such a truck to efficiently climb a hill or mountain in a way that would overheat and overwhelm a lesser electric drive. In fact, Mahle estimates the dual-SCT electric axle could push a 35-tonne fuel-cell-electric truck up and over the Brenner Alpine mountain pass between Austria and Italy 10% faster than a diesel truck, shaving roughly 3.5 minutes off the commute from Innsbruck to Bolzano.

Alternatively, SCT units could power heavy-duty agricultural or construction machinery at full load for extended periods of time, allowing them to get more work done. Or they could open up an electric sports coupe to multiple accelerative bursts in a short time period, allowing it to pass several different cars at different times on a highway or track.

Mahle revealed the dual-SCT electric truck axle as part of the same theoretical fuel-cell truck exhibit that highlighted its biomimetic cooling fan. It said at the IAA show that both the SCT motor technology and accompanying liquid cooling system are ready for series production. It also reiterated that the motor can be specced without permanent magnets, a design that combines the SCT and MCT (Magnet-free Contactless Transmitter) technologies into a single "perfect motor."

Source: Mahle