Axial flux motors have really started to make some noise in the electric mobility market of late. Adding to the hype, British market innovator YASA announced that it's opening a state-of-the-art "super factory" to boost production beyond 25,000 axial flux e-machines a year. Those ultra-slim, potent pancake motors will find their way into a variety of world-class vehicles from the likes of Lamborghini and Ferrari.

Spun-off from Oxford University in 2009, YASA has spent the past decade and a half working to solve the performance obstacles and manufacturing problems that have held axial flux motor technology back since the likes of Michael Faraday and Nikola Tesla explored it in the 1800s.

After some early concepts, racing prototypes and aftermarket kits, YASA motors made their production car debut in the absolutely cutting-edge Koenigsegg Regera hybrid. Series production followed for the motors that Ferrari used in the Stradale SF90 hybrid in 2019. Of course, the company has also worked closely with Mercedes-Benz, which acquired it in 2021.

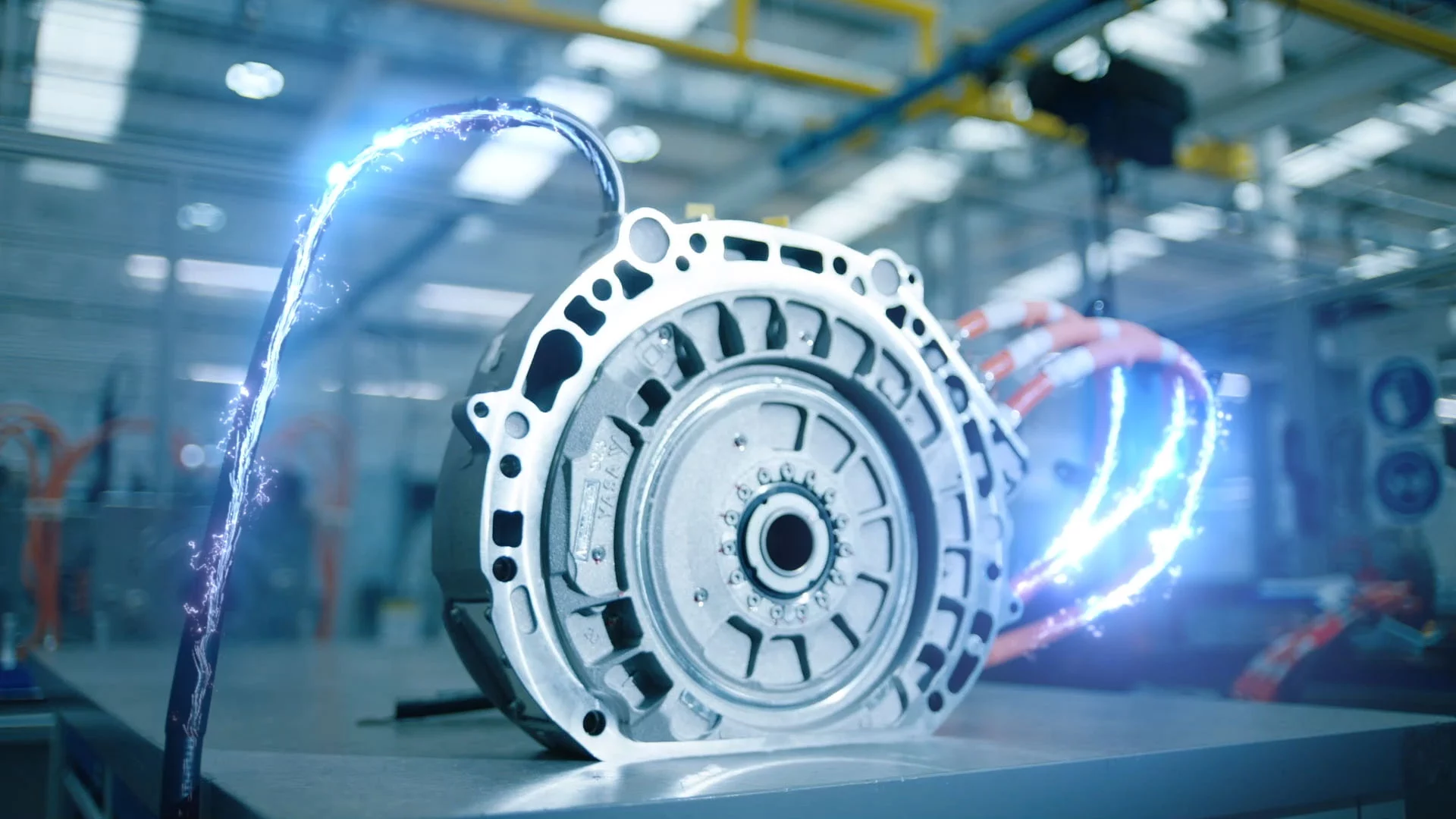

YASA announced this month that it has officially opened the doors of an upgraded manufacturing facility at its headquarters in the village of Yarnton, just outside Oxford, UK. The upgraded 60,000-sq-ft (5,574-sq-m) plant puts to work a £12m (US$16m) investment toward boosting manufacturing capacity and setting new benchmarks in electric motor technology. YASA aims to scale annual production upward of 25,000 units.

YASA calls the upgraded plant the world’s most advanced axial-flux electric motor manufacturing facility, and considering how much of an innovational leader the company has been in the space, we're inclined to believe it. The facility brings all production processes under the same roof for a seamless manufacturing ecosystem with the enhanced automation and efficiency necessary for intricate, quality-focused production.

New state-of-the-art machinery and tooling features prominently in the upgraded facility, including uniquely constructed coil and bar manufacturing cells with CNC coil winding, high-capacity ovens, stator laser welding, and rotor balancing with sixfold accuracy improvement.

"Each of the numerous technical manufacturing advances we have implemented during the factory transformation consolidates YASA’s ability to outpace and outperform all existing radial flux technology by delivering more compact, lightweight electric propulsion systems," said Andy North, YASA commercial director.

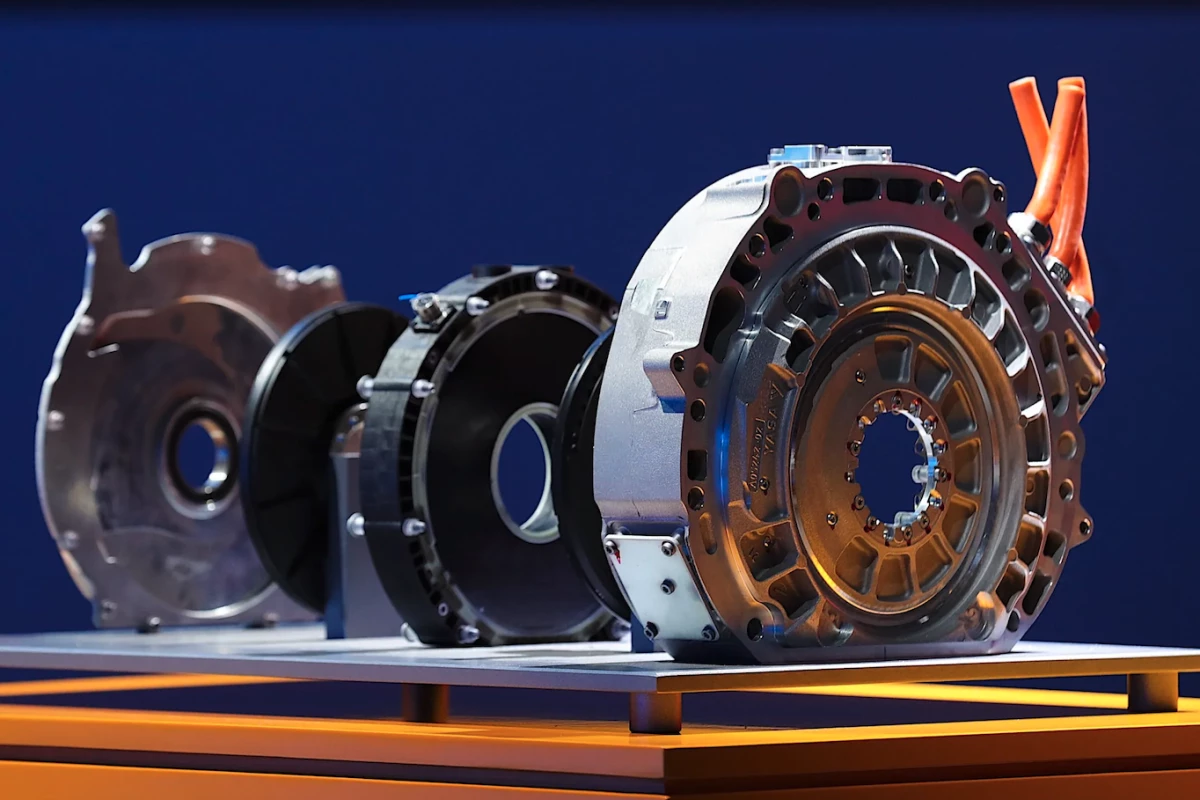

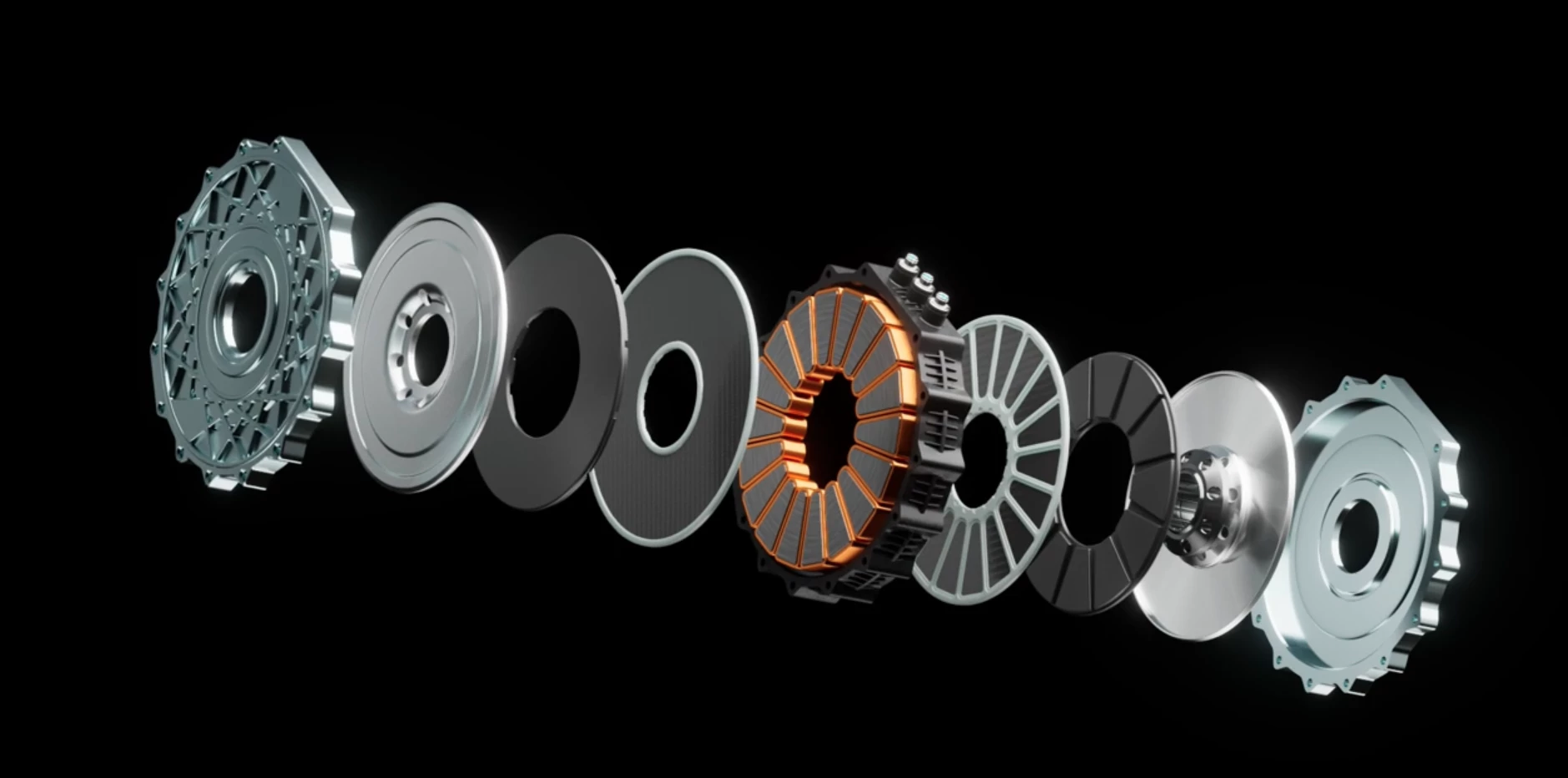

YASA says its slimline axial flux motors produce up to four times more torque and offer double the power density of common radial flux motors while also weighing 50% less and measuring 80% thinner. As an example, one specific motor it's put into production under Mercedes ownership pulls up to 480 hp (353 kW) and 800 Nm (590 lb-ft) of torque out of a 24-kg (53-lb) package, a highly impressive power density of 14.7 kW/kg.

Most recently, YASA has helped Lamborghini continue its electrification journey by supplying the e-motors behind its new High Performance Electrified Vehicle (HPEV) family. Lamborghini's two newest debuts are part of this family, benefitting from YASA's compact, powerful e-machine topography.

The Temerario relies on three 148-hp (110-kW) YASA motors working with its twin-turbo V8 engine to develop up to 907 hp. Each of those YASA units weighs 17.3 kg (38 lb) and puts out up to 300 Nm (221 lb-ft) of torque. The even more powerful Revuelto couples that same trio of motors with Lamborghini's all-new V12 engine toward a total system output of 1,001 hp.

Source: YASA