In a breakthrough for bio-based materials, scientists have made leather from the fibers of discarded pineapple leaves that's comparable to the real thing and also outperforms other existing plant products. The strong and sustainable material, which comprehensively outperformed mushroom-based leather, has great potential to be produced at much larger scale for everything from clothing to bags and shoes.

Using natural rubber for adhesion, researchers from Thailand's Mahidol University created this 100% bio-based pineapple leaf fiber (PALF) leather through a simple process that does away with chemical treatment or additional plastics, which they say is a "significant" step forward.

"This research showcases a sustainable and economically viable alternative to traditional leather, with the potential to revolutionize the leather industry and contribute to a more environmentally friendly future," the team noted.

While animal leather alternatives are not new, they have so far come with significant challenges. 'Vegan leather,' which relies heavily on plastics in production, may be better for animals but not necessarily the planet, and has been shown to have a much shorter lifespan. There have been major steps forward in using other natural fibers, such as those found in fungi, but their mechanical properties (toughness, tear resistance) have been an ongoing issue.

So what makes pineapple a more likely source for a leather that's produced sustainably and holds its own when it comes to wear and tear? It all comes down to the extraction and preparation of the tiny fibers. The leaves – a plentiful byproduct – were cleaned and chopped into 6-mm-wide pieces. These were then ground into a thick green paste and dried, then sieved to separate non-fibrous material from the pineapple leaf fibers (PALF). The researchers then prepared both untreated PALF (UPALF) and fibers that were mixed with sodium hydroxide and washed (TPALF), to create different leather properties, and spread out on a silkscreen, similar to paper-making processes. Finally, a thin coat of natural latex was applied to the unwoven, flattened fiber sheets, which were then exposed to 70 °C (158 °F) for 24 hours and later compressed.

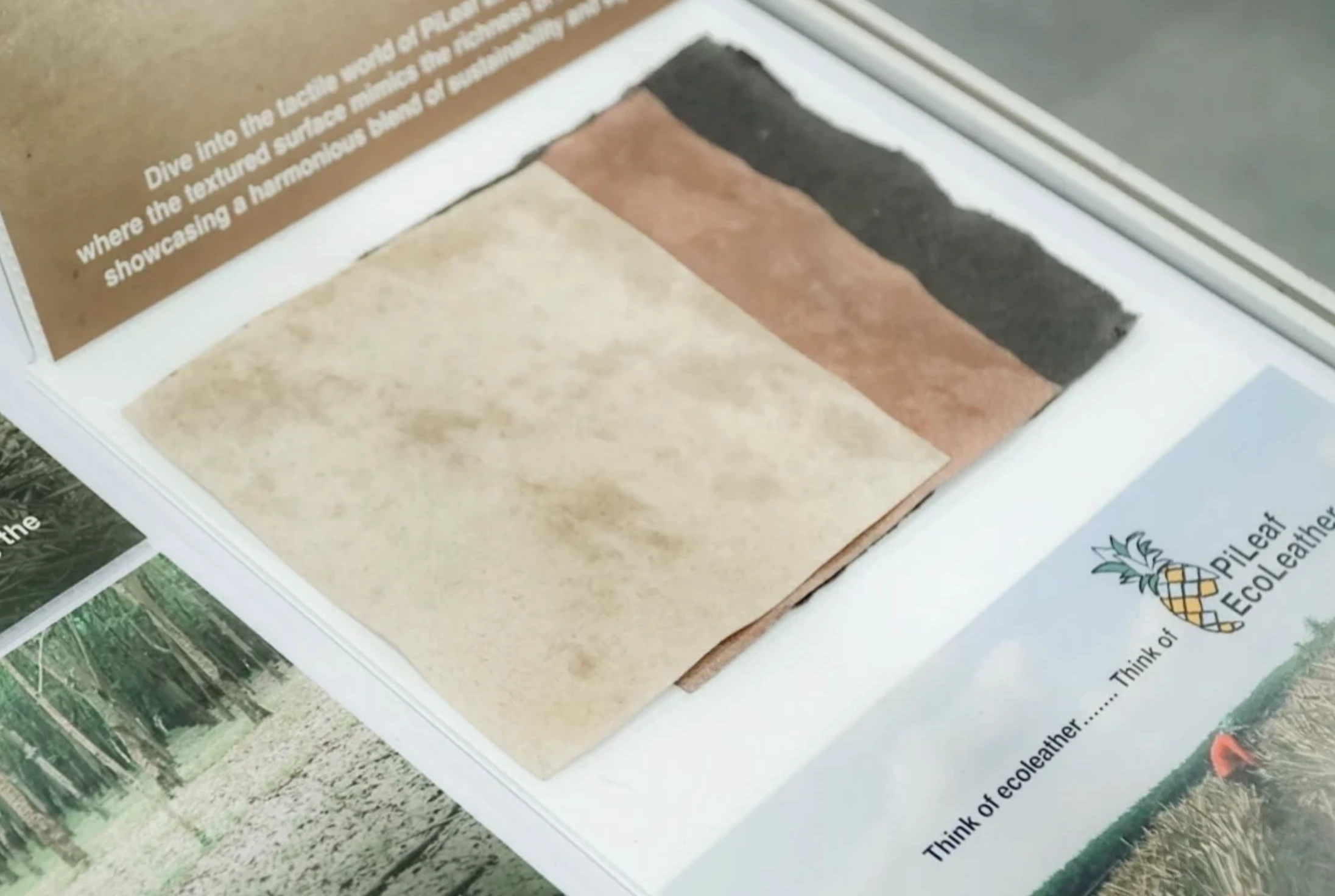

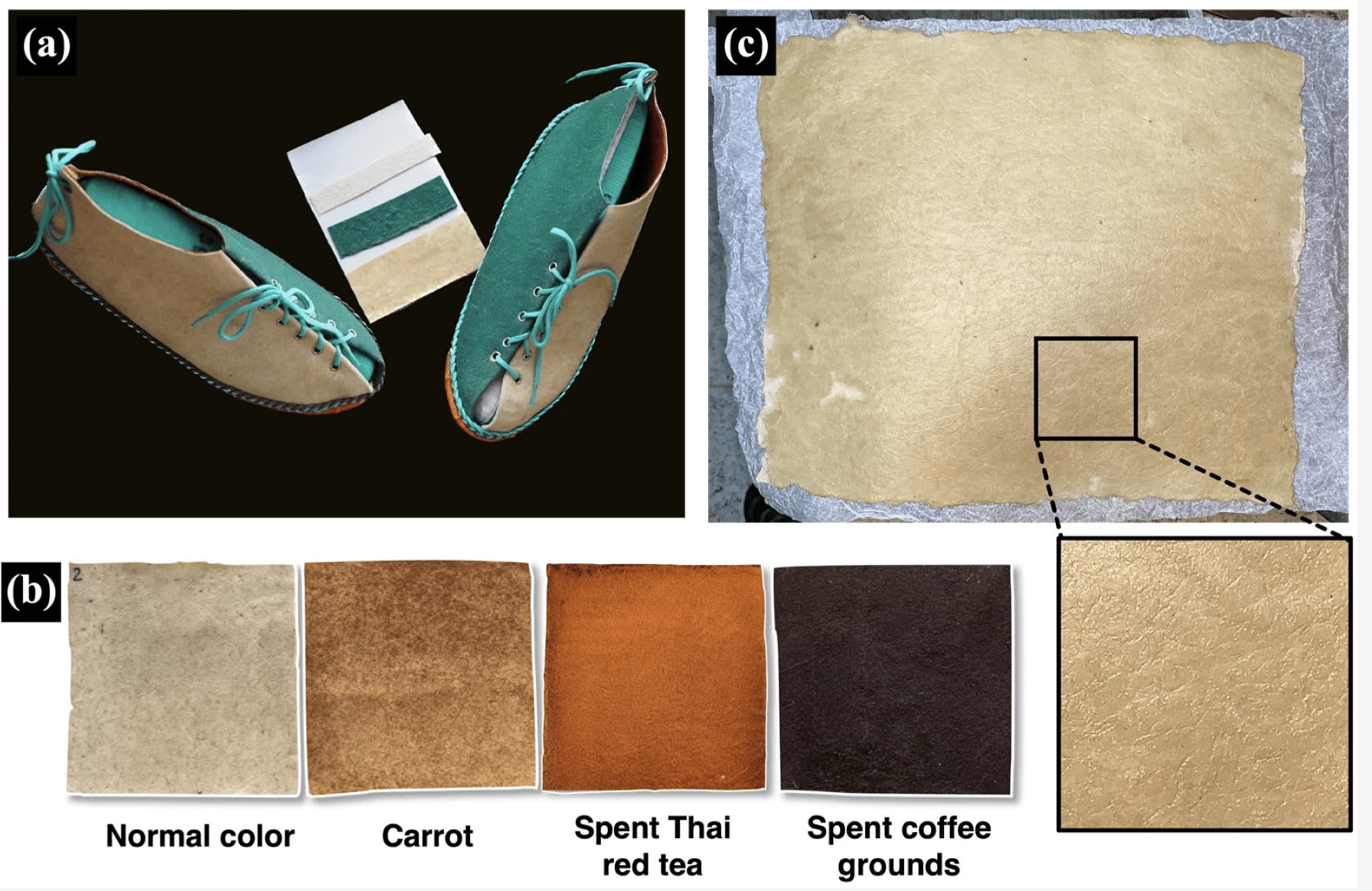

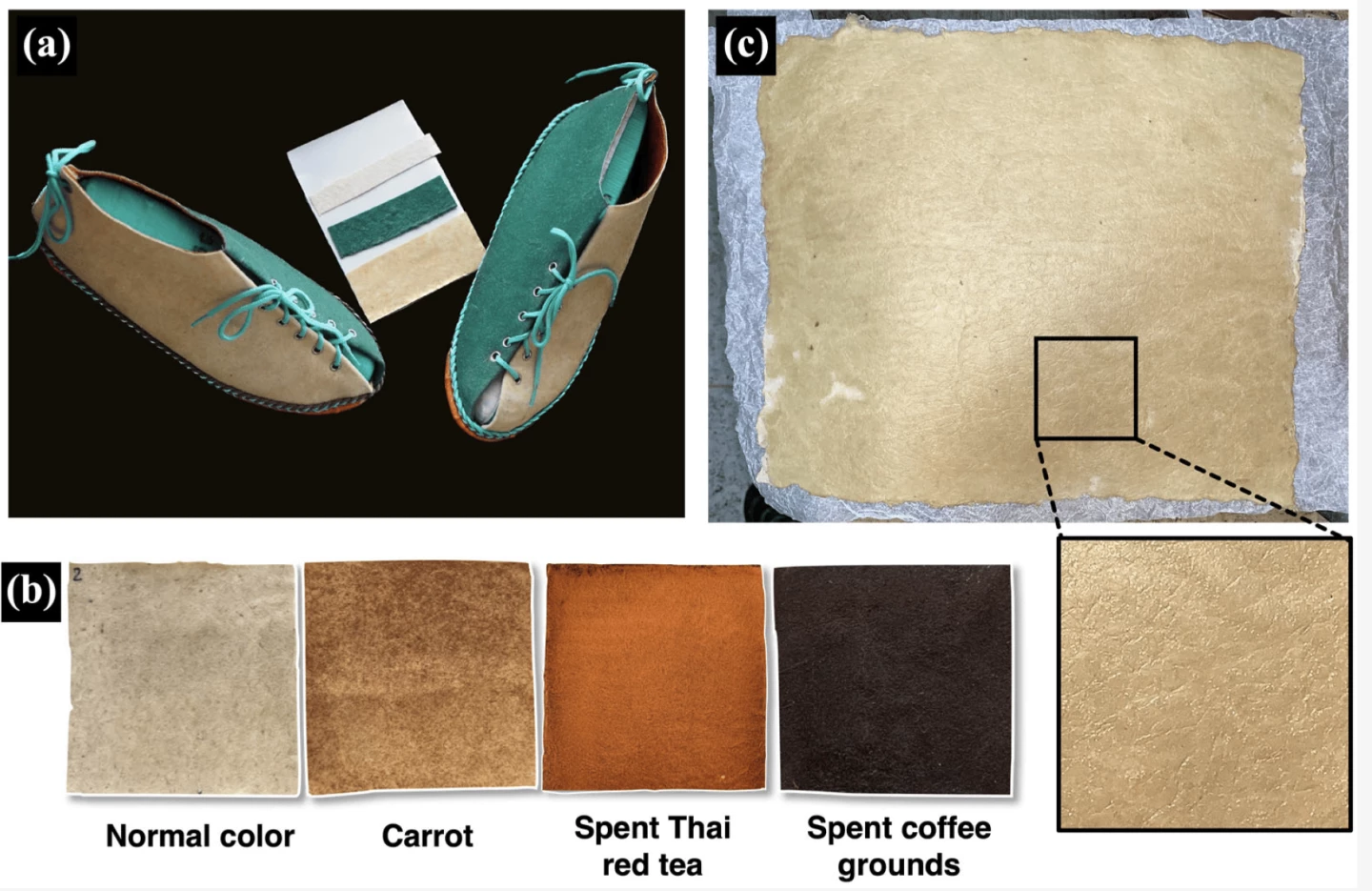

The researchers landed on a treatment that, when analyzed using a scanning electron microscope, had a structure that performed best in tensile and tear strength tests and optimal hardness. These leather sheets were also treated with a variety of natural stains, from carrot to coffee, to demonstrate how a variety of tones could be achieved without needing any of the toxic chemicals used in commercial tanning.

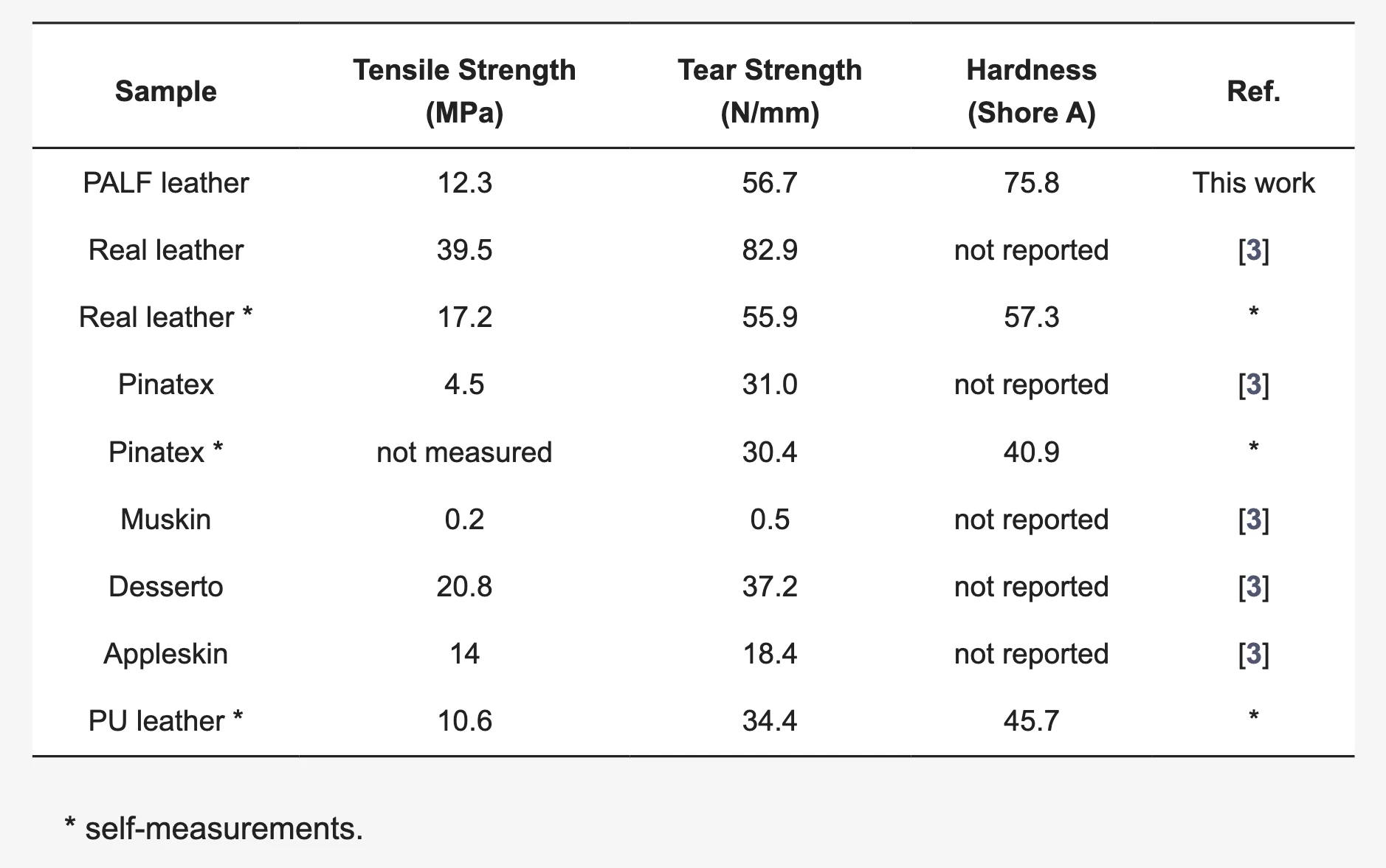

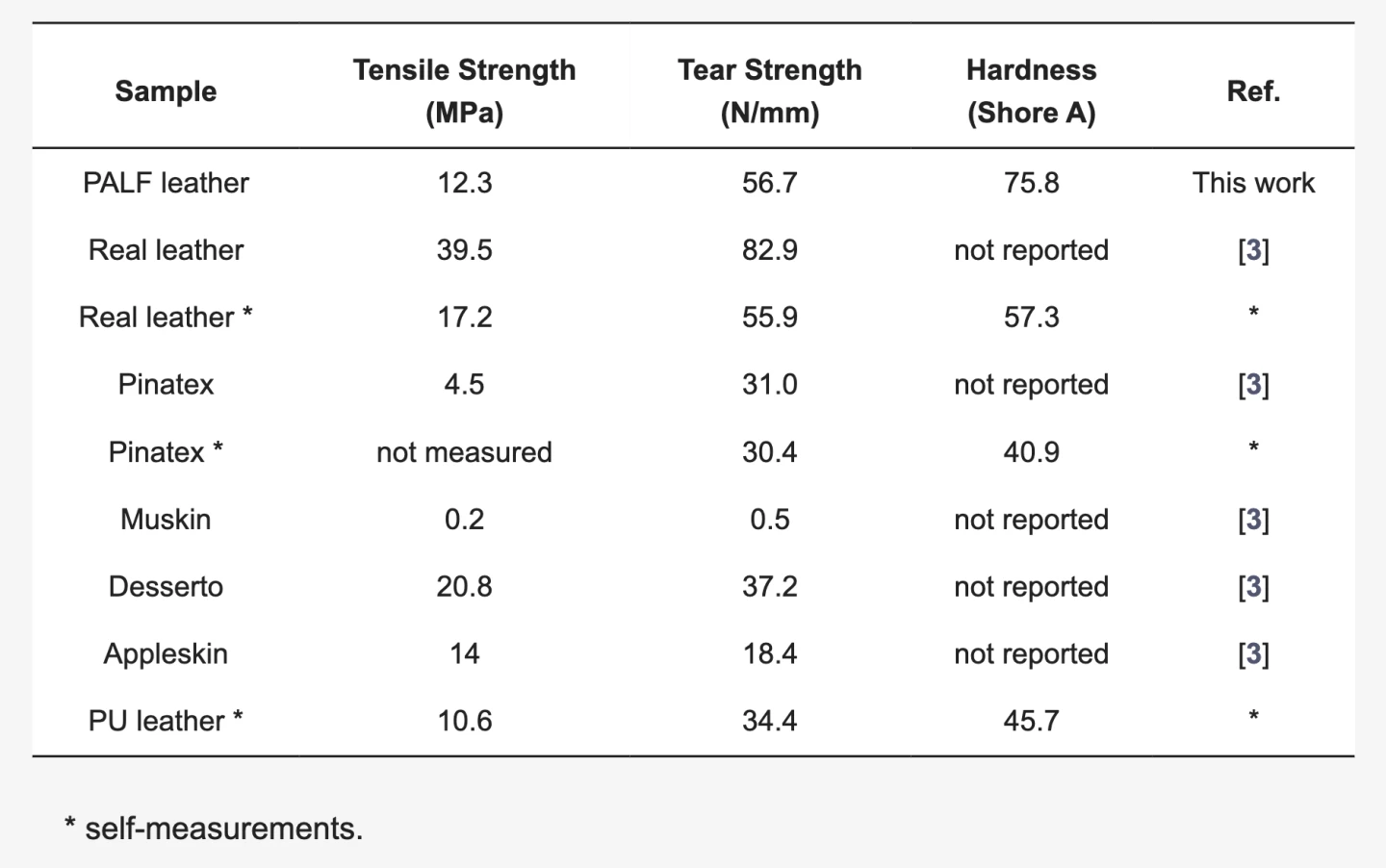

While the PALF leather had lower tensile strength and tear resistance to what is expected of animal leathers, they were comparable when the researchers performed their own tests, suggesting natural variability in traditional materials. PALF, however, was especially impressive when measured up against existing commercial leather alternatives, showing to have a tensile strength of 12.3 MPa, more than 60 times tougher than MuSkin (made from Phellinus ellipsoideus mushrooms) at 0.2 MPa. This poor 'wear and tear' factor has been one of the large concerns with mushroom and some other plant-based leather alternatives.

PALF was nearly three times stronger and had a tear resistance of almost double that of existing pineapple leaf leather Pinatex.

The research team, led by Professor Taweechai Amornsakchai, plans to now work on adjusting the material's feel, to have it more closely resemble the softness typical of animal leather.

The research was published in the journal Sustainability and Amornsakchai explains the leather-making process in this 2019 video.

Source: Mahidol University via Asia Research News