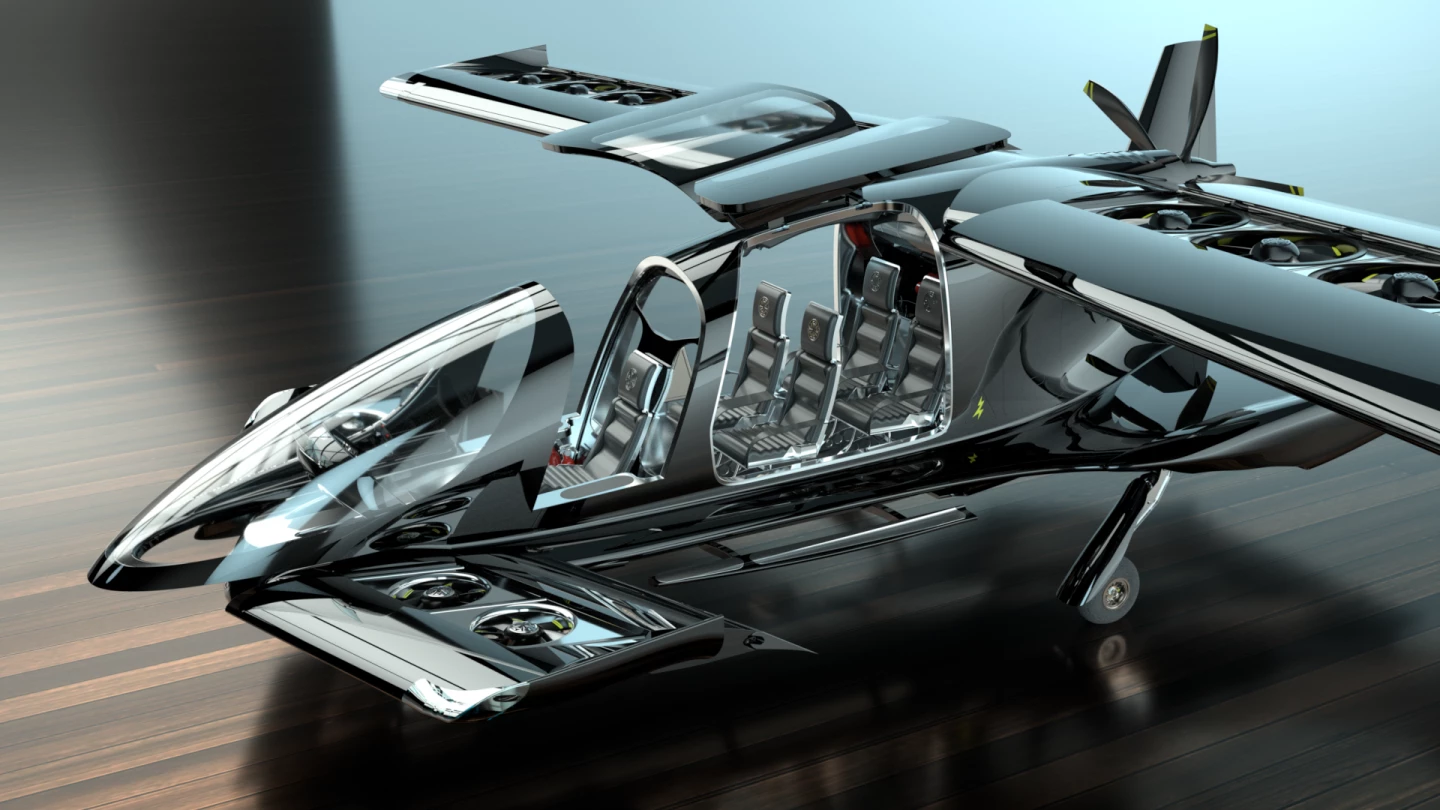

Canada's Horizon Aircraft has popped up out of stealth mode with an interesting 5-seat hybrid eVTOL design using a wicked-cool split-wing mechanism to transition between VTOL and horizontal flight, and a totally unique path to market.

Cavorite is a word invented by H.G. Wells in his 1901 book The First Men in the Moon. In the book, it's a metal alloy, created by a Mr. Cavor, which, when cool, is able to cancel out the effects of gravity on anything it covers. Thus, Cavor uses it as the heart of a fin-de-seicle spacecraft, opening and closing windows in a shielding mechanism surrounding a Cavorite sphere and effectively controlling the effects of gravity itself as a propulsion system. Lots of fun, and an appropriately anti-gravitational name for a vertical-lift five-seater like this, the Cavorite X5.

Horizon Aircraft, based in Lindsay just outside Toronto, Ontario, has made a name for itself primarily as an engine conversion company specializing in the task of putting GM LS-series V8 motors into kit planes. The Cavorite X5 started out as something completely different – a project to create a modern high-lift, hybrid-electric cargo version of the amphibious Republic RC-3 SeaBee sport plane. But father-and-son team Brian and Brandon Robinson quickly realized that adding a vertical lift system would make for a long-range, high-speed air taxi design that could offer a ton of operational flexibility.

The X5 is a five-seat canard-style plane with a large pusher prop at the back. Its large, forward swept main wing and smaller, swept-back front canard wing offer a high degree of lift for taking off and landing on short strips. Where VTOL is required, these wings split apart in the middle to reveal arrays of ducted fans, six along each rear wing and two in each front wing, turning the X5 into a 16-rotor, self-balancing multicopter.

Once in forward flight, the wings close over, restoring the aerodynamically-efficient shape of a standard wing. Horizon claims that with an LS V8 engine on board and a relatively modest battery system, the Cavorite X5 will offer fully-loaded ranges up to 310 miles (500 km) with 215 mph (350 km/h) cruise capability and the ability to fill up and fly home on pump gas. Unladen with cargo or passengers, it'll fly more than 625 miles (1,000 km).

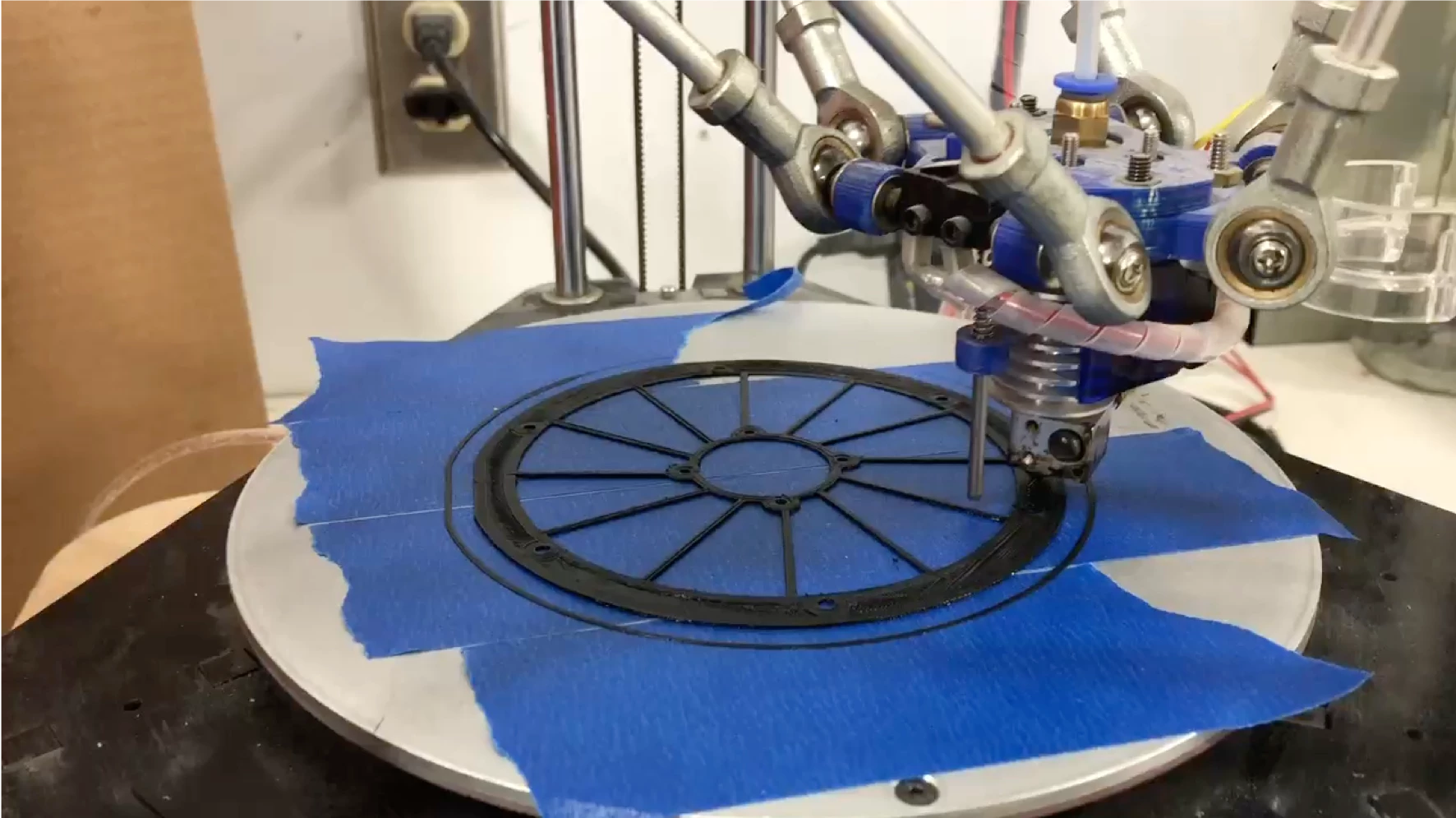

Practically-minded, the company is currently working on a 1:6 scale version to begin testing its systems and software, and plans to have a half-scale machine built in the next 12 months. Low-volume production is slated for 2024, at which point Horizon hopes to sell the X5 first as a kit plane in the amateur-built experimental category. That's certainly an unusual approach, but Horizon's got its reasons.

We caught up with Horizon's Brandon Robinson on a video chat to talk about the aircraft, the technology, the emerging eVTOL market, the challenges of certification and the company's plans. What follows is an edited transcript.

Loz: Obviously this sector's going a bit bananas in the last few years as battery and drone technology made lights pop on above a lot of people's heads. What's the driver for you? What was missing in this market?

Brandon: It's a bit more organic than that to be honest. Before eVTOLs were popular, we were developing a hybrid-electric amphibious aircraft. We had a prototype design that has a couple of patents for its landing gear, for example, called the Horizon X3. We had a high level investor that was very interested in us building the next-generation amphibious aircraft. We're lucky enough to have an old Republic SeaBee at home, it's like a flying boat, a 1947-style airplane. We were building the modern version of that.

Hybrid-electric was our first step into the world of electric aircraft. My father Brian Robinson, very smart man, felt hybrid-electric makes too much sense for an aircraft. You need tons of power to take off, and then just a fraction of that when you're airborne and cruising somewhere. And for any emergency scenario, it'd be cool to have a hybrid-electric system where if anything happened to the combustion engine – run out of gas, throw a piston or something – we could decouple the two systems, and a high fidelity electric system could carry you to safety.

So we designed a hybrid-electric power system with a decoupling mechanism in the gear reduction drive. The gas engine spins at 3,600 rpm, and the prop spins at 1,800 rpm, so there's a gear reduction drive in there, and all we did was create a decoupling mechanism. So with a small battery, if the combustion engine goes out, you've got enough power to safely land instead of having to start looking for a field to put it down in immediately.

It acted like an electric supercharger; it provided a ton of extra power on takeoff, and the engineering tradeoff was that we'd have to carry some extra weight in batteries. Realistically, we lowered the amount of fuel we'd carry and upped the weight of the battery, but it was compensated for by the fact that the engine was always operating at the optimum rpm for efficiency.

We could tune it extremely precisely. At 3,600 rpm, the GM V8 LS3 engine we were running at the time was super efficient – especially compared against aviation engines in its power class. We used to do a bunch of LS engine swaps for aircraft owners; it comes with air conditioning, it's more fuel efficient, more power ... Our aircraft at home went from 215 horsepower to 350 horsepower overnight, with significant weight and fuel savings.

Anyway, an overseas investor was very interested in our amphibious prototype, and he wanted to use it for last mile cargo transport. It wasn't extremely fast, but it could carry a lot of weight, and with the type of wing we were using, it was basically a short field aircraft.

I'd been interested in the emerging eVTOL marketplace. And my father and I just thought that with this miracle of modern electric power and batteries, we could have a distributed electric power system that could help the airplane get off the ground a lot faster, just by embedding some fans in the wing. We crunched out the math; there's a ton of data available on embedded fans, starting all the way back at embedded helicopter tail rotors. You know the thrust values. You know how much power you're going to need.

We came up with a patented way to close the wing. The whole idea was to design a machine around early use cases. Eventually, sure, these things will be flying from the top of one skyscraper to another and acting as taxis, but we wanted a machine that was ruggedized to work in the real world to hit the early use cases. Things like radioactive isotope transfer, things that helicopters are doing now, but that we can do faster and more efficiently. Medevac, some last-mile cargo, disaster relief-type stuff.

But realistically we wanted to take a normal airplane, and not mess with it too much. It needs to return to normal wing-borne lift as soon as possible. I come from an operational fighter pilot background, and we have helicopters on the search and rescue squadrons embedded at every base I was at. When you watch a helicopter take off, they don't rise up vertically for 500 feet. They transition to forward movement very quickly.

There's only one way to get an aircraft to take off straight up and down, and that's to blast air downward. You can use a helicopter to do it, or if you want to shrink the rotor disc, you gotta just add power. The smaller the rotor, the more power you'll need. So we'll need a lot of power, but as soon as humanly possible, we'll transition to forward flight, get the wing covers closed over and become a normal plane again.

It's a screw drive mechanism, it's quite well engineered. And you spend 99 percent of the mission acting like a modern airplane. And with modern technology, you can automate a lot of it. If the airplane gets too slow, and you're coming in for a vertical approach, you have your destination input, it knows the latest weather, the density altitude, your weight and centre of gravity, and it'll give you the red light/green light thumbs up or thumbs down for a transition to a vertical landing. It'll auto-deploy.

There are two sections per wing that come out in a sequenced fashion. The tail section of it is a specially designed airfoil shape to help mitigate some of the pitching moments that occur when the wings open.

Normally a wing's center of pressure is near the center of the wing – maybe a little bit forward. But when those sections open up, the forward section creates a lot of lift, and you get a pitch-up moment. So the tail is specially crafted, with an elevator at the back that's got enough authority to counteract that adverse pitching moment.

The center of gravity is a bit delicate; you can see the forward sweep of the wing, that helps to mitigate that; kind of cool aesthetically, but it's also functional. And we still need a little extra help, so a canard system works well. We can take off on just the main wing thrusters, but the front ones are there to balance things.

So with a regular multicopter, you can just about get the software to run them off the shelf now. But when you start to build a transitioning aircraft, and wing lift starts coming in, and you've also got a variable shape wing, things get a lot more complex. Who are you working with in terms of flight control software and that side of things?

Initially, our sub scale prototype is going to fly first. To be quite honest, that's where we're at. All the computer modeling has been done, aerodynamic analysis and basic CFD stuff. We want to bring it into the real world as soon as possible. We're going to fly our 17 percent scale model in the next two months. It's almost finished. Then we're working on a 50 percent scale.

So the transition modeling is the key. Not only have we done our own CFD analysis, we're also working with a doctor at the University of Toledo, who, it so happens, has a complimentary patent for boundary layer control on a fan-in-wing system exactly like ours.

He's come up with a way to help with flow separation. After you take off vertically, with the wing still open, and you start to transition forward, the forward edge of the fan array will start to stall a little bit. The air can't make a 90-degree bend with that forward motion component.

So there's an active boundary layer control system that engages and blows high-pressure air on that inlet. He's done a lot of analysis in that area and he's helping us out with our full unsteady RANS (Reynolds averaged Navier-Stokes simulations) – the top-line NASA-level aerodynamic analysis.

His claim to fame is that NASA called him to help solve a shuttle problem while it was in space. Apparently on launch it blew off one of the back doors where the parachute comes off where it lands, and they needed some aerodynamic analysis done, so they called this guy.

No pressure then!

Indeed! Anyway, he said ours was one of the best eVTOL designs he's seen so far from a practical perspective.

So you're using this compressed air system to solve that fan stall issue on this aircraft?

We actually want to use a passive system. His active flow control system uses compressed air, but my father reckons it'll be too heavy for this project. So the first thing we're doing is building a full-scale wing so we can test it to see what kind of stall conditions there are.

Will you need a wind tunnel for that?

We don't. To be honest, the biggest problem with a wind tunnel is the boundary conditions. You'd need such a small wing section, or such a big wind tunnel that you get into Reynolds numbers problems. It's not that practical. The walls of the wind tunnel affect the recirculation and give you false values. You've gotta be really careful with VTOLs in the wind tunnel. The chamber size dramatically affects the outcomes.

So honestly, we're going to build it and turn it on and see how it works, to be super cruise about it. An iron bird sort of approach. For a stall condition, it's easy to set up a bunch of fans, or wait for the right wind condition.

A few years ago, it might have been Joby, but somebody had their wing on top of a truck, and they were just driving it along testing that way.

Honestly, that's the type of practical engineering that'll actually work. I think a lot of people spend too much time in computer simulation, and don't bring their ideas into the real world soon enough. We're more of a practical team, my old man builds things for a living, he's an old-school engineer. He has a natural mistrust for what comes out of a computer, and wants to confirm it. We have a lot of good renderings, but we put stock into building things in the real world to see how they work.

In terms of the software, what's the approach? Where will you get it from?

The software for the 17 percent scale will be the standard self-stabilizing software. You hook it all up, we'll be using a LiDAR for pixelization and stabilization, and you just give it the basic dimensions and geometry, and it's a fancy octacopter.

Then, we'll be going to work on the custom software for the transition phase, and that'll be the more challenging phase.

You guys will do that yourselves?

We will. My brother-in-law's a software engineer, and we have access to some pretty smart folks. The initial plan is to do it ourselves. We'll partner with Honeywell from a flight controller perspective – well, a lot of the components will be Honeywell components, whether they officially partner with us or not. Who knows?

We think the software portion will be challenging, and a lot of work, but it's not rocket science. (Laughs) I can see by your face that you think we're underestimating it, and I understand that!

I'm no aviation designer! It just seems like a complex problem. And the self-balancing multicopter stuff, yeah you can get that off the shelf, but there's no transitioning hobby drones on the market, DJI doesn't make a transitioning drone ... Maybe there's an opportunity for somebody there. There's so many companies working on this at the air taxi scale, if somebody was to build a transitioning aircraft at the hobbyist level, maybe that could end up underpinning the software in these human-scale eVTOLs and getting a lot of these problems solved.

That's a good point! I hadn't really considered it. We've been so focused on our primary problems: figuring out the battery system, making sure it's light enough, keeping it cool enough, extracting the amount of power we need for hover.

I don't know how some of these eVTOL companies are going to do it. I've been around the handle about 17 times on various VTOL designs, and some of them, I don't know how they're planning to have any endurance whatsoever when they bring it into the real world. Particularly the ones that use a ton of small fans; the power load is going to be huge, and without a single larger cruise prop somewhere they look like they'll be very inefficient in horizontal flight, too. Considering that endurance is a huge limiting factor in this segment, some of it looks like form over function.

There's some really beautiful designs out there that just don't look like they'll work in bad weather, bad light, bad conditions, scrambling to deal with contingencies. From a fighter pilot's perspective, you need some operational flexibility. I don't really know how a pure electric aircraft is going to do that operationally.

Again, they might prove useful carrying people 50 km from here to there once that whole thing gets sorted out. But in the short to medium term, the practical use cases won't be taking a person from one skyscraper to another, it'll be more of a functional approach.

A lot of the market's just relying on better energy storage tech coming along. I'd see a lot of eVTOLs as being energy technology independent. It doesn't strike me as a killer problem to go from a battery-electric design to a hydrogen-electric design, or indeed a hybrid thing with a range-extending turbine, or whatever it might be. I think everyone's just getting the dynamics sorted out. And of course the biggest problem, which is getting all this gear certified and legal for commercial operations.

Well, from a certification perspective, what I like about our design specifically is that we can talk to the FAA regulators and say "look, this is a normal airplane. It never has to be a VTOL. The VTOL portion of this airplane is just a layer of safety on top. It's automated, if you go too slow, instead of the airplane stalling, the wings open and it hangs out. It's good to go."

That's an interesting perspective. Not a lot of these eVTOLs have the capability to do a conventional takeoff or landing.

Yeah, and from an operational robustness perspective too, if you ding a fan, or a bird or some rocks go through one of them after landing in some weird place, you just keep the wings closed. As long as you have a thousand feet of dirt road to get the thing airborne with – and that's all you need with a high-lift wing – you can operate it like a normal airplane.

Of course, the FAA regulator will want to talk about the vertical portion. Ten to the minus nine redundancy, all that sort of stuff. Sure. We'll have a conversation around that. But the initial conversation is really that this is a normal airplane that's been augmented to provide additional layers of safety and additional operational flexibility. We see that as a powerful narrative for us.

But there's definitely things to figure out, and we'll of course have to certify its vertical operation. But this airplane could be built with normal wings, too. As a secondary market, it's a perfectly functional and decent airplane. If you rip those fancy wings off and put on normal ones, it'll be a fast, cool, new normal aircraft. It doesn't have to be VTOL. That's way down in the contingencies, but it makes for an interesting conversation with the regulatory bodies.

Have you started a conversation with regulators yet?

No. We have to get on that. We only came up about two months ago, we've been in stealth mode until we got our patents locked away and our ideas coalesced a bit. But you're right, that's a conversation we want to start sooner rather than later.

We want to get our 17 percent scale up and functioning, that should get the attention of some folks and hopefully build up enough momentum that the regulators might start calling us back!

Where are you at on the prototype?

Interesting story. We have the fuselage and wings all built and assembled. It's going in for paint shortly. But it came out so good that we decided to build a second one that's a breakable version. Exactly the same mass properties, but it's made way cheaper. We're putting all the control system, the autopilot, everything into this breakable version. We'll get everything untangled from a hovering perspective, and do a bit of transition flying as well. Once that's sorted out in private, we'll transplant it into the highly finished new body.

(Laughs) So you made one to test and then said "no! This is too pretty!"

(Laughs) Honestly, that's exactly what happened.

What's the wingspan on this 17 percent scale version?

About 7 feet.

When do you expect to get into the transition testing?

I'd say around April-May. We'll have the control system sorted out by the end of February, and we'll start doing the real transition testing on the high-fidelity prototype somewhere in that timeframe.

That seems pretty soon!

Yep. Well, we've been at it for a while, and these things always take longer and cost way more than you want them to, but we think sooner rather than later.

Awesome. So the big question is commercially, how will you make this work? Getting to a full-scale prototype and into production. What's the dream, what's the plans, and are you getting traction with cash on this stuff?

Great question Loz. The initial answer is ideally we'll get all the kinks worked out in the amateur-built experimental category. So not necessarily have to go for full certification right away, to be able to sell it before full FAA certification, which could end up being a 100-million dollar effort.

I've heard even scarier numbers than that!

Yeah, anywhere from 50 million to 500 million plus. Maybe even up to a billion dollars or more to certify these things. For sure, we get that.

So are we getting traction? Yeah. We're getting a huge amount of interest already and we've only been pushing it for a couple of months. It's hard to separate the wheat from the chaff, to be honest. A lot of folks say they're going to write a check, and the reality of who's actually willing to transfer money into the bank account to keep things going, well that's a different thing.

So we'll close a seed round here hopefully in the next three months. That'll get us through to the end of a 50 percent scale prototype. That includes bringing Transport Canada and the FAA in on certification and starting that conversation. But we'd love to be able to sell it as an experimental amateur build across North America first.

I haven't really heard anyone else talking about that kind of approach either.

There's some conversations to be had there as well. Again, the fact that it could be sold as just a normal aircraft with an additional layer of safety ... We don't know what Transport Canada or the FAA would think, but perhaps you could restrict it to certain flight envelopes initially until you gather enough data, then you could start selling it with restricted modes, or at the end of the day, just sell it with normal wings and no crazy VTOL stuff.

There's a number of ways to skin that cat. Most of them require some significant capital, so we're looking for that right now.

When you say it's hard to separate the wheat from the chaff, I imagine investors are probably finding the same issue.

Yeah. I do feel for them. There's a lot of BS out there. We think we have a unique solution, but it's up to us to prove it. That's where practical engineering, considering real-world operational environments, building a machine that's not just a fancy render is pretty important to us.

That's our advantage right now. There's a lot of designs out there, but from an investor's perspective, it's a challenging thing to figure out. 19 out of 20 of them probably won't work out.

Yeah, any one of these seems like a long shot. Maybe Joby's the exception at this point, because they've got such massive backing behind them now with Toyota, their ownership of Uber Elevate, they've probably been out there working on this longer than anyone else as well ...

That's something not a lot of people appreciate. They have done a great job, I've got no stones to throw Joby's way. They've done a fantastic job, it's a great design, it makes sense, it'll be practically usable in the real world, and now they have deep pockets.

So with a wing that's 40 feet wide, how does that compare to the main rotor for helipad operations?

I've never been asked that question!

Just looking it up now, a Robinson R22 helicopter has a 25-foot rotor, so you're looking at something a fair bit wider. Does that large wing, which is so good for efficiency and conventional takeoffs, restrict you from certain helipads?

Well, as usual that's something my dad's spent some time thinking about. He doesn't sleep! There are H1, H2 and H3 helipads, the H1 being the smallest. The max rotor diameter for landing on an H1 helipad is 15 meters, 49.5 feet or so, so pending confirmation from the regulators, we should be fine for H1 to H3 helipad operations. It's more of a certification question than anything else at this point.

But you're really not pitching toward the air taxi thing to start with anyway, you want to get this thing in the air doing other jobs first?

Yeah. I think there'll be folks willing to pay for that versatility. There'll be a very significant VTOL portion of what they do, but for the most part, until regulatory environments become more permissive and the infrastructure is sorted out, they're going to be operating in traditional aircraft modes. Practically speaking, I think they'll be going in and out of normal airports a lot to start with, and much less often they'll be landing on some skyscraper, or a helipad on some guy's yacht. Those will be more rare uses of the aircraft.

But at the point where these things become a commuting option, they need to be able to go to places that are not airports. That's the whole idea, buying out these parking garages and sticking vertiports on top. Nobody's gonna get excited about flying between airports, they can do that already.

Right, and they need to be economical at that point, and that's where you talk about your pure air taxi. That pure electric architecture, once that energy storage problem is solved, is much simpler and cheaper to operate if it's done correctly.

We also have to solve problems like duty cycle; how it's going to work in the real world so the economics make sense. A high duty cycle is going to mean you'll have to either take out the batteries and swap them, or have some crazy fast charging mechanism that doesn't exist right now.

Once all that gets figured out – and I have no doubt that it will, there's some amazing battery technologies for instance coming online using carbon nanotubes and the like – once that's figured out, the pure electric machines will be an economical way to travel around big cities. It just makes too much sense.

I spent a lot of time operating out of Miramar near San Diego. And we'd take off at a Westerly heading, right over Torrey Pines, and I'd look North, and see twelve lanes of traffic, and six of them would be at a standstill. You go up 500 feet, and there's nothing happening. It's a matter of time, but we'll definitely start using that third dimension.

It's an exciting space. There's a lot to be figured out still, especially when you get into the hardcore business case analysis of how these things will operate profitably and economically, but it's an exciting market segment for sure.

So what's your timeline for the next 5-10 years?

We'll have our 50 percent prototype, which is pretty big for the sector, flying within 12 months. Two years after that, we'll be doing initial testing on the full scale. Low volume production we're planning for 2024.

We're going to start slow, you build the prototype, get all the wrinkles out, then you build two of them using the same moulds, then 8 after that, and keep ramping it up. Then you're into new production moulds, new production facilities, all that sort of stuff. Initial low-volume production in 2024 would be ideal.

My father was in advanced pharmaceutical manufacturing. He spent the early part of his career building production lines, and spent his life in aerospace as well. So when it comes to building things that can be built, and putting together production facilities and machines and understanding manufacturing, he's definitely above average. And that's something that's been part of our design from the start, setting it up for success.

We thank Brandon Robinson for his time, and look forward to following Horizon's progress as work continues on the Cavorite X5. You can see the split-wing mechanism operating in the short video below.

Source: Horizon Aircraft