If electrics aren't yet ready to take over in the motorcycling world, maybe forced induction could rule the next era. Honda has just dropped a revolutionary large-capacity V3 combustion engine at EICMA, with an electric supercharger.

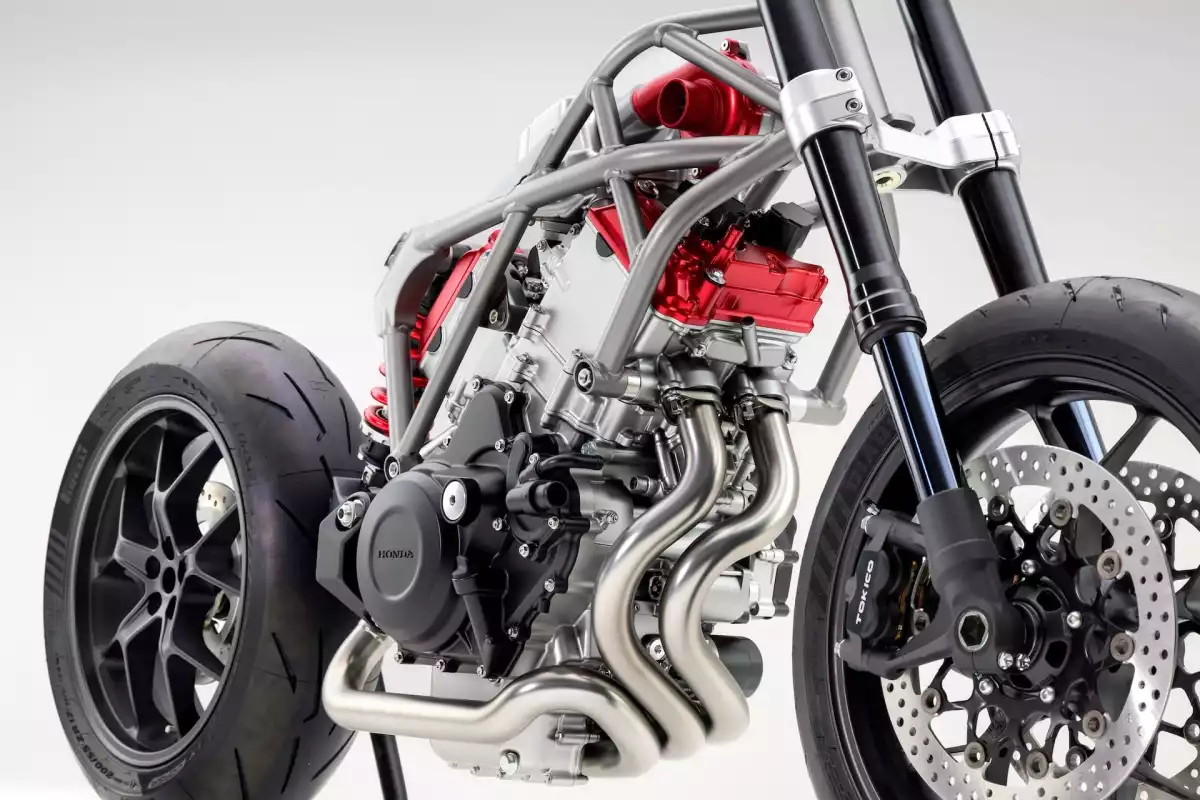

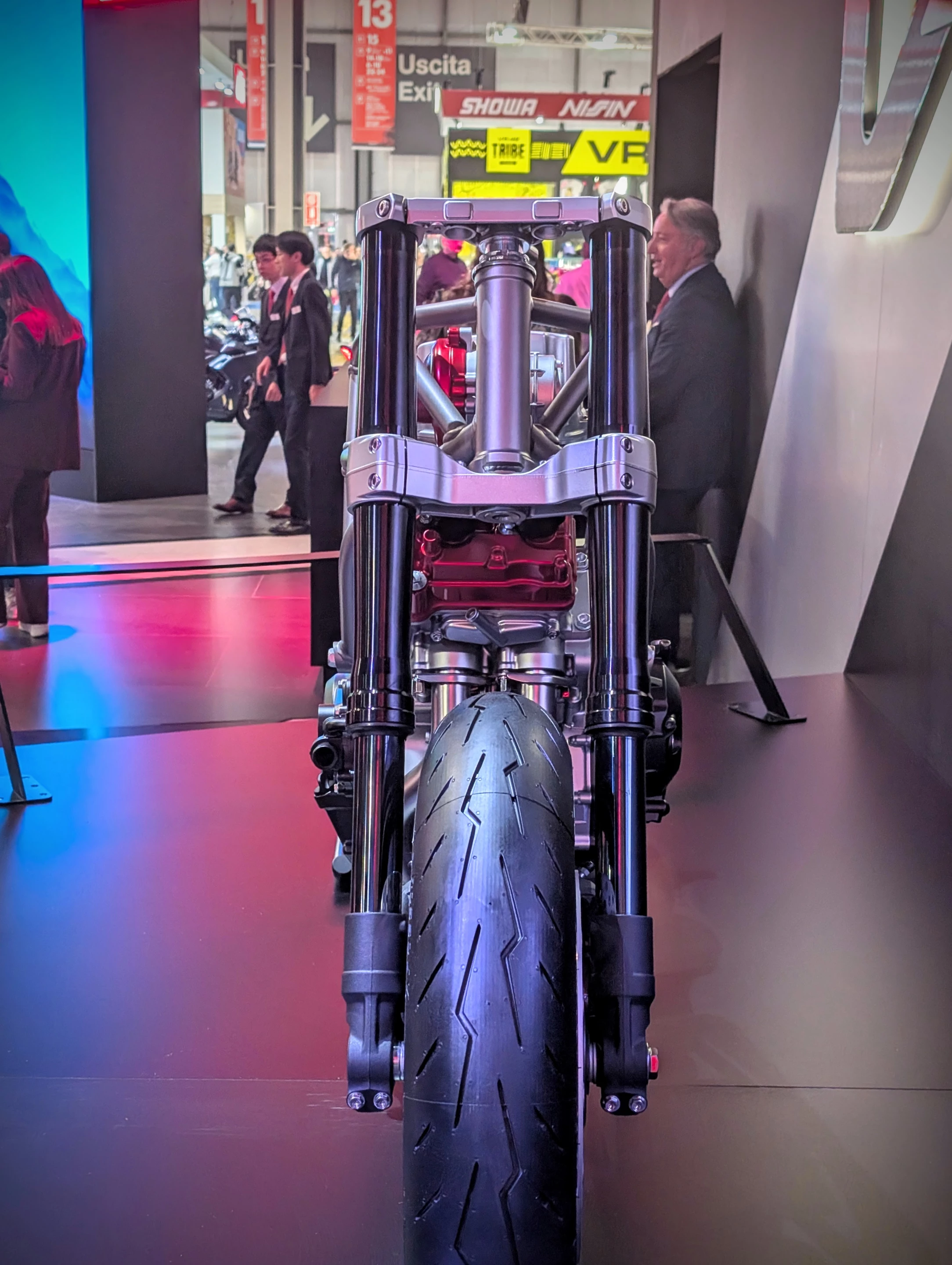

The Japanese giant unveiled an all-new platform just after lunch on Tuesday: a compact V3 4-stroke engine, which it revealed in a drop-dead gorgeous tubular trellis frame with red highlights on the two front cylinder heads, the single rear cylinder head and the small snail of the electric compressor peeking through the frame above the front heads.

It's slim – barely wider than the forks, with beautifully curved exhausts that could look great in a naked setting, and an easily-accessible oil filter off to the left side. Front-bank valve clearances, though, are going to be a pain.

The pistons are positioned at a 75-degree angle and the whole thing is water-cooled - not that you can see any radiators on the presentation chassis. The electric compressor is a world-first in this kind of application, designed particularly to boost torque at low and medium revs.

Where turbochargers run off exhaust gas pressure, and superchargers are driven directly off the engine's output shaft, Honda's e-compressor runs off battery power. This completely decouples it from engine speed; the ECU can force as much air into the intakes as it wants at any time. Honda's engineers can use this to completely eliminate any kind of lag waiting for the boost to kick in, or tune it for all kinds of efficiency and performance gains.

We'd be fascinated to know how the efficiency of this overall system will compare to traditional belt-driven superchargers, which sap a meaningful percentage of an engine's power at low revs before they spin up and start contributing. Honda still needs to get the power to drive that snail from somewhere – this bike will need a substantially higher energy output from its alternator, and probably a larger battery, to run this compressor.

Typically, the losses involved in converting mechanical energy to electrical energy and back again have made electric superchargers less efficient than those driven directly off the motor – but the overall riding experience might still end up being superior here.

The V3 E-compressor was created from the ground up and is incredibly compact. Honda claims that the engine is "being newly developed for larger displacement machines," and we can see it being used in all sorts of applications, from street and touring to more track-focused machines – heck, if it's as finely tuneable as it looks, it could even work in the adventure sector.

Remember, though, this is still a concept. The fact that it is shown fitted on a chassis with 200/55 wide section tires doesn't mean it's destined for service in the Fireblade. It'll be some time before Honda reveals where it'll start using this thing.

It shares the same cylinder layout as the NS400R 2T – a one-off, two-stroke triple that made waves some 40 years ago. And should it make it through to production, it'll join Kawasaki's terrifying H2 as one of the only forced-induction production motorcycles on the market.

And production is indeed the intention here. “Honda sees the development of this V3 engine with an electrical compressor as a new challenge in the area of internal combustion engines, and its goal is to enable customers to further experience the joy of riding and owning a motorcycle,” reads a company press release. Honda also stated that this new three-cylinder concept's "development will continue towards mass output."

Is it too soon to be excited?

Source: Honda