China controls about 90% of the entire global supply of rare earth magnets, including their mining and refining. That means that most of the neodymium, dysprosium, and terbium that end up in EV motors, drones, wind turbines and even smartphones ... well, depending on supply and demand or even geopolitical landscape, China basically makes the rules.

California-based Conifer Motors is trying to break that stranglehold by simply cutting rare earth materials out of the equation and making EV motors from one of the most abundant materials on Earth: iron.

Yes, it's been tried before. Iron-based magnets have historically been considered too weak for any serious heavy-duty use, but Conifer has a trick up its sleeve: an axial-flux design.

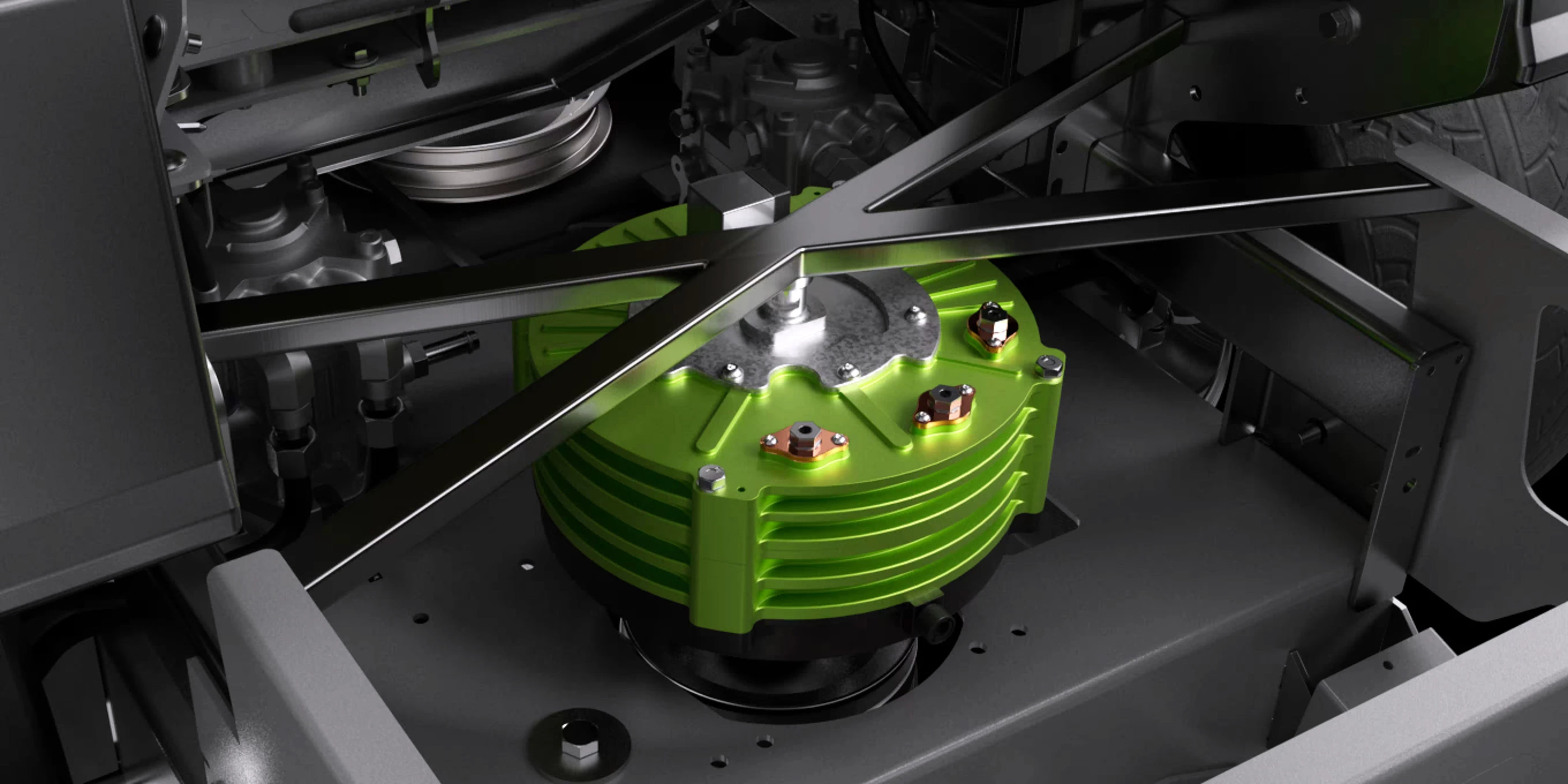

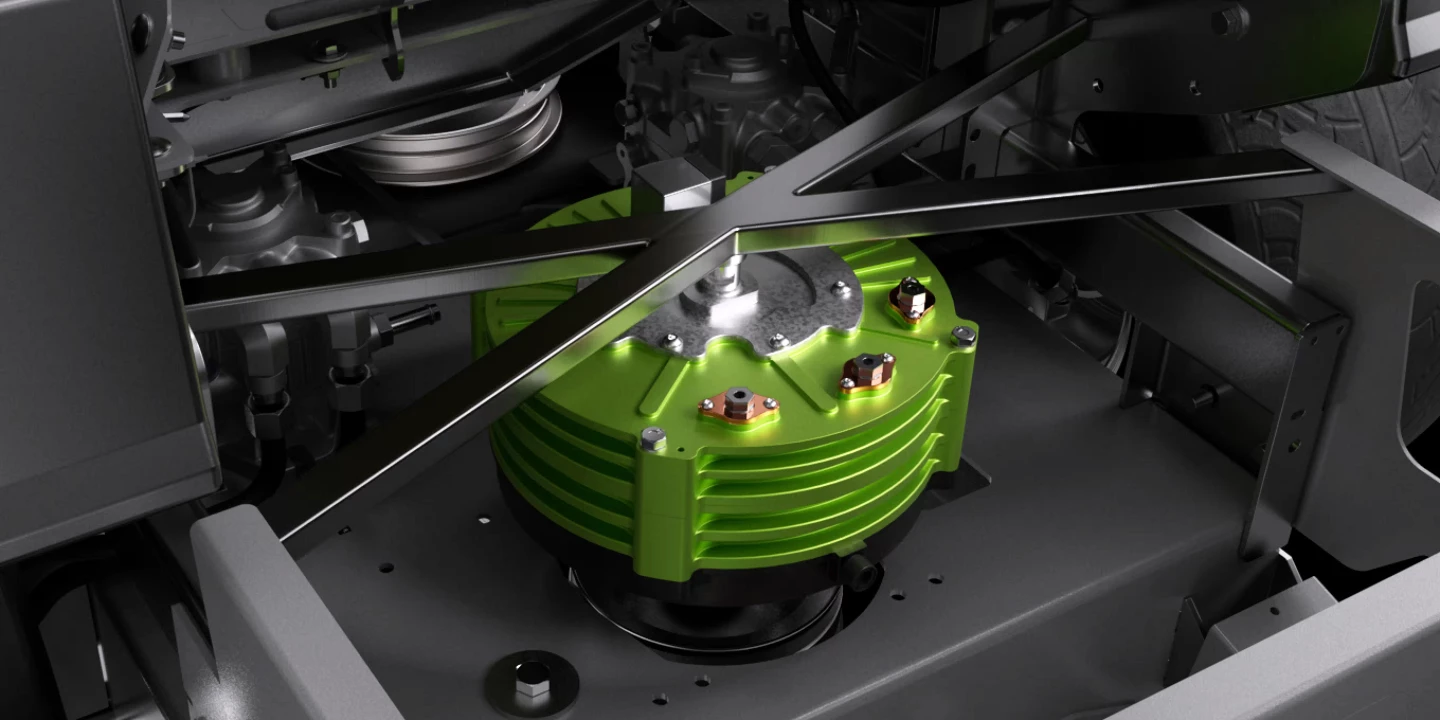

Most electric motors are radial-flux. That is, they are cylindrical with magnets spinning around a central shaft, which makes them simple, reliable and scalable. Axial flux, on the other hand, is more like a flat disk. Like a tuna can (axial) instead of a soda can (radial). These motors generally run lower RPMs and produce more torque due to their wider radius and shorter magnetic path.

Axial-flux motors have been around since the 1800s. Even Nikola Tesla dabbled with early designs, but the motors never really caught on because they were hard to manufacture and not easy to keep cool. And radial-flux, as I mentioned, was simply good enough to get the job done while being easy to make (for sanity's sake, we'll not even get into raxial-flux in this article).

Now, in the 21st century, we have all sorts of fun new tech that allows us to not only easily manufacture axial-flux electric motors, but also to make them much more efficient. Modern motor controllers, better thermal management, precision manufacturing techniques like CNC machining, lighter and stronger materials, you name it.

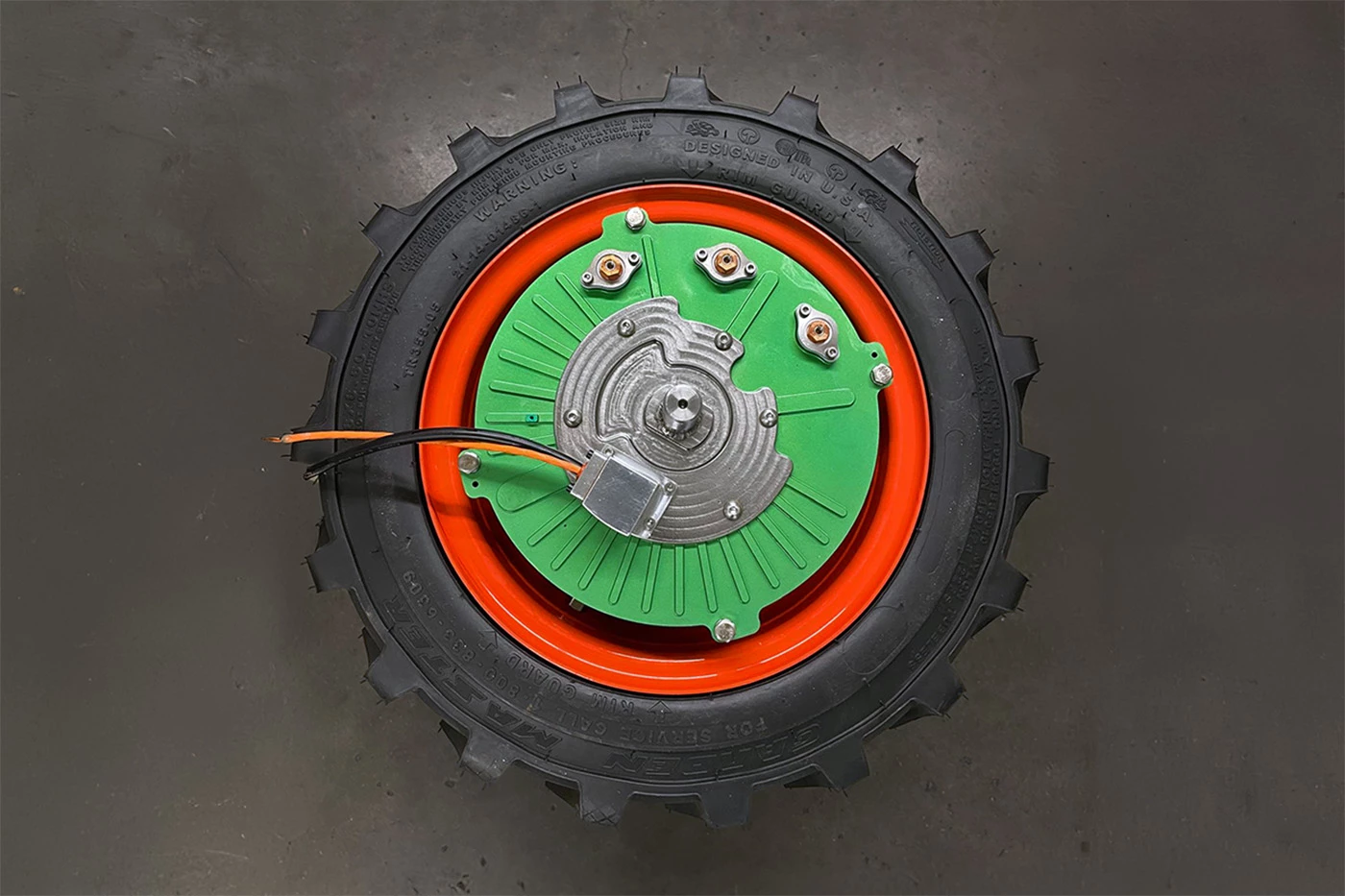

Conifer isn't trying to break into the electric car market with these new iron-based axial-flux motors. Instead, the company is focusing on smaller 1 to 25-hp (0.75-18.65-kW) electric motor applications for stuff like HVAC fans and pumps, tools and equipment, and even fun stuff like in-wheel motor designs for small electric vehicles and off-road toys – think scooters, ATVs, and urban delivery vehicles.

All of these things already exist, but the kicker with Conifer is that these are ferrite axial-flux motors rather than rare earth magnet motors. And iron can be sourced nearly anywhere; domestic manufacturing without any rare earth hoops to jump through.

Conifer's in-wheel design simplifies everything: no axles, no differentials, and no other powertrain bits, making the entire vehicle project less complex and less expensive with less energy loss in transmissions, CV joints and the like. It also has the potential for better traction control systems, as each drive wheel would have its own motor.

The company utilizes a winding technique normally reserved for battery production that cuts winding costs down by 90% and shortens production time. Normally, stators are wound using manual coil insertion or complex lacing machines. Conifer uses a flat, layered winding approach inspired by battery cell stacking – then automated it to be scalable without needing custom retooling for different-sized motors.

Conifer's smart axial-flux layout puts more magnetic mass further from the axis of rotation and spins the motors faster than traditional axial designs – kind of utilizing the flywheel effect – to achieve higher efficiency and more torque. But that also means slower acceleration and deceleration with heavier braking loads. Fortunately, in applications like blower motors for AC units or small urban commuter scooters and the like, more inertia isn't a bad thing.

All of that being said, iron magnets are simply not as powerful as rare earth magnets. It's very unlikely you'll ever see iron magnets used in EVs like a Tesla, Lucid, Rivian or any other proper road-going electric car. And while in-wheel motors are compact and convenient, unsprung weight (weight that is not loaded onto the suspension) does affect ride quality and handling, especially in lighter two-wheeled machines.

But when push comes to shove, being able to locally source the main ingredients to build these motors without being dependent on international laws, rules, supply chains, politics, or anything else ... Well, that's the real win.

Source: Conifer