On a recent trip to Europe, I got in touch with the Lilium team and asked if I could come visit the company HQ outside Munich. On late notice, thanks to my slapstick organisational skills, the team went out of their way to pull together a full afternoon program for me.

This included a tour around the factory where serial production on Lilium's eVTOL "air minibus" is slated to begin once certification is complete, as well as the chance to fly the Lilium Jet around New York City in a motion-rig VR simulator.

I also had my first chance to lay eyes on a full-size mockup of the 7-seat aircraft. Let me tell you, friends, Lilium's excellent press photos simply can't capture the sheer, awe-inspiring presence of this machine. I've been looking at photos and renders for six or seven years now, but seeing this extraordinary bird in the flesh was absolutely breathtaking. People are going to lose their freakin' minds when they first see one of these things coming in for a vertical landing. It's like nothing I've ever seen before.

But the first stop on my mini-tour was a chance to sit down with Lilium Chief Engineer for Innovation and Future Programs and co-founder Daniel Wiegand, for a general chat about progress, conforming prototypes, flight testing, certification, fundraising, batteries, pricing and more. What follows is an edited transcript.

Loz: How's it all going? Where are you at? What's happening?

Daniel Wiegand: Well, this year we're really focused on starting production of the conforming aircraft. And that's an incredibly big step for any aerospace program. You spend years of development, of design, of discussion with the regulators of which requirements you have to fulfil to be finally compliant.

And when you start production of a conforming aircraft, the word conforming means it's conforming to the aerospace standard, or to the requirements of the regulators. And that basically implies you now have the maturity on everything that's required for that.

You have to put a pin in your design: "this is the one that we're going to make."

It's a design freeze. And that means you have to have the maturity on the regulations. If you don't know what to comply with, there's no point in designing something. You have to have the maturity on technology, on supply chain and on your own design, bringing all these elements together. And this is where we are at right now.

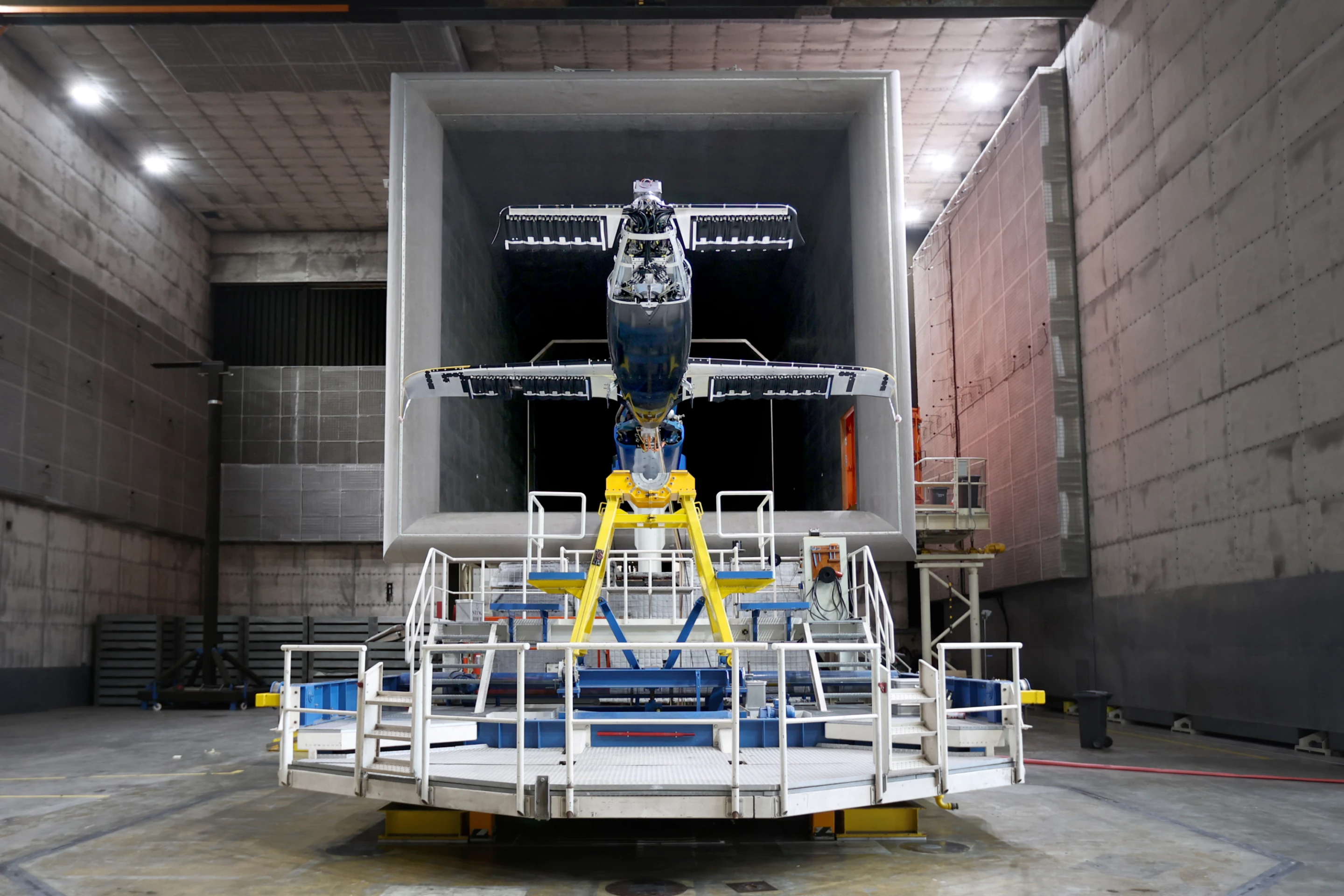

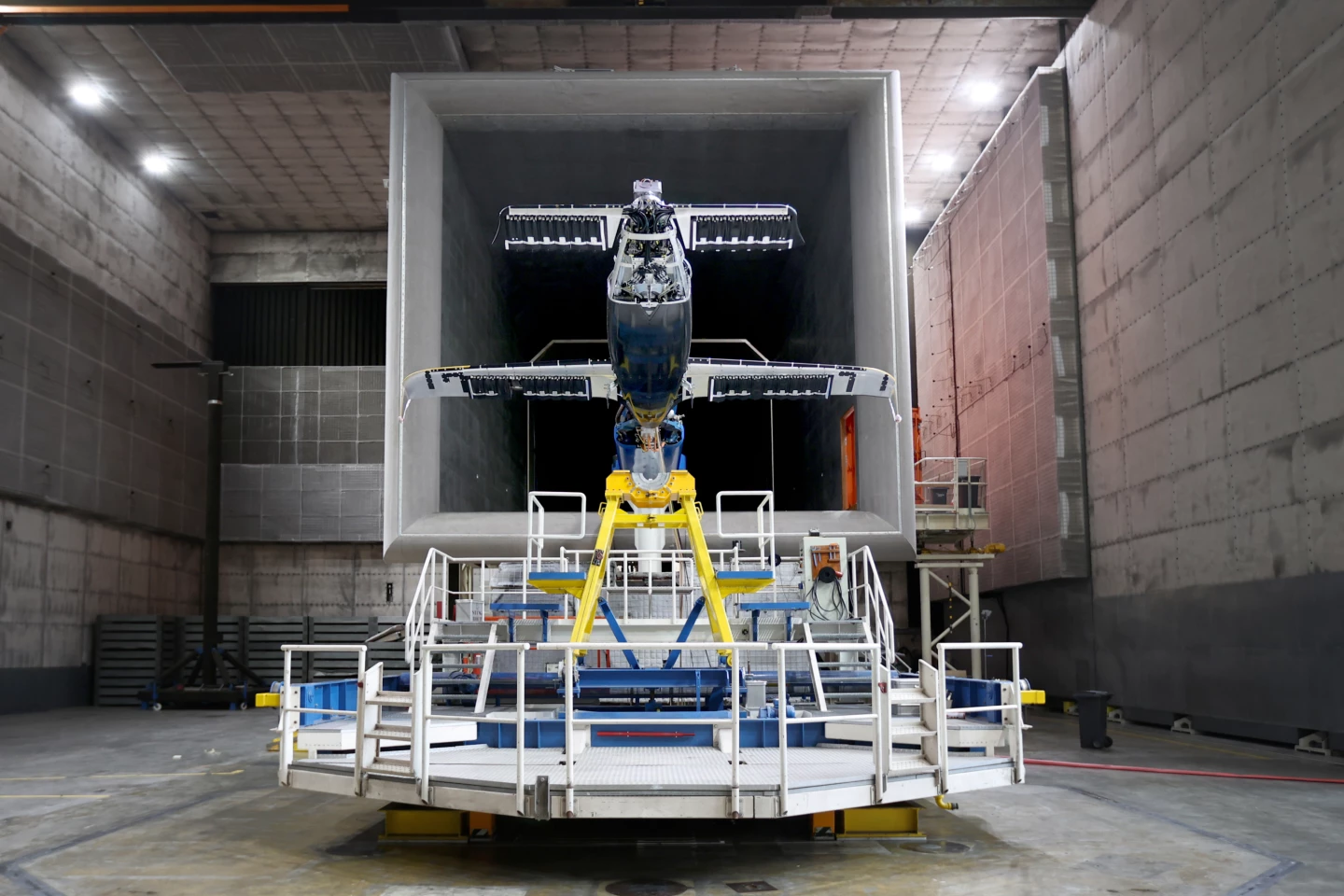

Last summer, we had some great successes in the flight test campaign in Spain, testing the whole envelope of different maneuvers from high speed flight, to transition flight, to different tests of component failures, ground effects, how does the aircraft behave with a reflection of the ground. So these were great successes.

And for this year, the focus is now on the start of production, which means we have actually started cutting metal on the molds for the composite parts of the airframe. We're milling the first metal frames in the next couple of weeks. These will come together into a fuselage, which then, towards the fourth quarter of this year, comes to our site here, where we'll do the final assembly of the conforming aircraft.

So there's a general rule set that needs to be conformed to but then there's also the means of compliance?

Yeah. There's basically two levels. So the top level is about 200 rules, which in our case, the European regulator has laid out in a document called SC-VTOL – special conditions for VTOL aircraft. It's the bucket for requirements, which they apply to everybody in the industry who wants to fly in Europe. And then underneath that, you have so-called means of compliance and certification plans in which you detail how you want to demonstrate compliance.

So practically, if you take a top-level requirement, like 'the aircraft needs to do a safe landing after a bird strike.' Okay, right. Understood, very simple. But there's actually a ton of questions which an engineer would come up with saying, how fast is that bird coming? From what direction? How big's the bird? What density is the bird? Which elements of the aircraft are impacted by the bird? If there's an impact on the windshield, is it acceptable to have a crack or not? All these details are described and discussed and aligned in the means of compliance and certification plans.

Sounds like a nightmare.

It's great, honestly. Initially when I came into this aerospace environment, I had the same reaction. But on the other side it's great because it gives you predictability. Some people think you design, and in the end, you certify, and there's a big question – maybe you'll get certification and maybe you won't. That's not the case. If you have an up-front agreement on the requirements you have to fulfil, plus how you'll fulfil them, you have a very clear roadmap against which you can engineer and work with your team.

That gives your team a lot of predictability in a complex environment; you won't have late changes coming in that cause hundreds of engineers to need to redesign, and suppliers needing to make changes, it's a great system. The European regulator EASA has done a great job for the industry, in the sense that they were the first globally to establish a fully consistent set of regulations for this industry. And they apply the same to everyone, so it's a level playing field.

Whereas all other countries, including the US, either don't yet have a framework, or they have proposed something in draft status, which is in consultation in the market. And they then have different rules for each applicant, which makes it very difficult to make a level playing field as well. And so here, I think they have done a really good job.

Some people think you design, and in the end, you certify, and there's a big question – maybe you'll get certification and maybe you won't. That's not the case.

And then there's China, where they're going, 'you know what, just take passengers, go ahead!'

The Chinese are quite ambitious, usually, with respect to safety, they have the target to have the highest safety regulation established in aerospace.

And yet they're letting people take flights in autonomous eVTOLs now, I think they have been for like a year.

Not commercially. It's test flights.

Some of them look an awful lot like scenic tourist operations! But in Europe and the US, nobody's doing manned flights, it's safety, safety, safety. It just seems like a totally different approach over there. Bit of an arms race scenario, maybe, where they're willing to bend the rules a bit more.

Our conforming aircraft will fly manned next year. That's going to be our first manned flight. And that's what everybody is focused on right now.

And then what else? Well, we had a big success recently with the batteries, on the cycle life. Ionblox is the designer, they provide the chemistry of the cells. And Customcells here in Germany is producing the cells. We had two big successes recently. One was that we had a US lab independently test the cycle life of the cells. Because one of the big challenges when you go for new chemistries that are more performant than traditional ones, is usually that they provide the energy and power you want, but not over many cycles.

So one of the question marks that people had out there was how many cycles do these new batteries have? And we had an amazing result. After 800 cycles, 88% of the capacity was still available. Our target was 80%. So their cells were more than 50% better than expected. And to put this in context for you, this is at least as good as a result as what you normally get with standard cells in an electric car today.

Right, but they're much higher specific energy, is that right?

Exactly. So the cells I'm talking about have higher power for the vertical landing – and they have higher energy for the range of the aircraft. So that's one of the key enablers that also gives us an edge in this market. One year ago, we independently tested the power and energy, so that was known in public already. The last open question basically was that cycle life.

And then of course, what comes into play is: can you produce those cells? I personally recently visited our supplier Customcells in Tubingen near Stuttgart. They're next to Mercedes and Porsche. And they now have a production line there where they are shipping cells to us of this new kind on a weekly basis with an amazing quality management system and production control. They're tracking 2,000 parameters for every single cell in thickness, chemistry, alignment of the layers of the cell, and so on.

They're sharing this with us via the quality management interface, to have the full aviation traceability from a safety point of view. So you can trace back for every single cell, every single parameter.

And that'll be part of certification eventually.

Yeah, exactly. So that, for me, has been one of the most exciting pieces, because when we built this company, and we said, 'we're gonna make an electric aviation company, and we believe that battery-electric aviation will take over all regional flights,' we were making a big bet on future batteries.

Basically, we applied Moore's law to the batteries and said, 'over the last 20 years, they improved at 6% per year. So we believe they will do the same over the next 20 years.' But there was no guarantee on that. So it's a big step for us to finally have those cells in hand from the production line – with all the data, with the cycle life, the production cost and the power that comes with it.

When we built this company... We were taking a big bet on future batteries.

We write about so many battery technologies, they all sound so exciting. But there's 50 parameters that you have to look at. It's like, alright, what's the specific energy by weight, the energy density by volume? Power output per kilogram? How long does it last? Does it have some way of preventing dendrite formation? How does it go in different temperatures? Does it use exotic or expensive metals? Does it catch on fire? It's not a simple matter of "how much further would my car go." But people do get excited about the idea of new batteries. Because if you make a better battery, you can have a better phone, you can have a better car, laptop, everything.

And the special thing for these batteries is that they don't stand out in one single feature. They don't, say, have the highest energy of all. There are some which have more energy, but these have the best balance across those five key features we care about: power, energy, cycle life, production readiness, and safety.

On the train on the way over, I had a look at the AAM Reality Index. And you guys were right up the top of there for ages, but they've dropped you right down in in the last few months. Do you have a sense of what's going on?

Yeah, it's because of the funding situation.

What's the funding situation? Sorry, I can't say I pay a lot of attention to the financial side of things.

It's public knowledge, we announced that by the end of last year, we had about 205 million euros in the bank account, which is not enough to certify the aircraft. So there's a runway throughout this year, but not into the next year and the year after. So they basically said, well, the market is challenging, you guys need to do more fundraising. And until then, there's a risk.

And also, if you look at what's happening on the stock market, this is a big topic. The funding situation. We're very actively working on that in the team right now. We have lots of conversations with different types of investors ranging from strategic investors, financial investors to state funding and research grants and so on.

[Since our visit to Lilium's Munich HQ, the company has announced an additional US$250-million funding round. Details can be found in a recent press release.]

Did you ever see The Wrong Trousers, that movie with Wallace and Gromit? At the end, Gromit's sitting on that model train, going a hundred miles an hour, and he's got an armful of track pieces, and he's kind of frantically putting the track down in front of him as he goes. I always get that image in my head when I think about startup funding.

That's a pretty good example of how it happens!

It must be exhausting, to want to be working on the product, and yet to have to run around asking for money all over the place

It's actually what we're used to. If you build a startup, you know, you need to raise money and you need investors. It's part of the job. From our perspective, it's like, okay, every year, we had to raise money. Now, it's the seventh time we have to raise money, and we're raising money.

We have the process, we have the conversations, we have the due diligence done, we're in negotiation with people. It's not so unique. What is unique is always the new context. So you always have a different economic environment, you have right now very high interest rates. So there's less money in the market, you have to shift a little bit which type of investor you are addressing. But overall, it's part of building new technologies that they need to get funded.

And you've got every faith you're on track to get through certification?

I think we are extremely well positioned. If I look at the rest of the planet, where either the regulation isn't there or the product is not mature or whatever, we are incredibly well positioned. Right now we have an extremely experienced team with respect to actually certifying aircraft, our whole leadership team are all ex-aerospace people, who've certified engines and aircraft. So the team is great. The team underneath is great with 450 aerospace engineers.

We have the supply chain together now – that's really, really big. I think sometimes it's underestimated, but 90% of the value of these aircraft gets produced and created in the supply chain. So having having all these guys under contract from the batteries, to the airframe, the engines, the avionics, etcetera, that's big. We have the regulation, we have the design and the technology in place. Flight testing went very well. So we have 100% confidence on that.

Awesome. I like the fact that you're going for something bigger than anybody else as well – this idea that you can fly farther and take more people, and cover a different use case from what everybody else is doing.

I've been thinking about where this came from. Because we were alone here when we founded the company and took these decisions on regional flight and more capacity, etc. We didn't yet know about the rest of the industry. And then later, we saw that there were actually a few other companies working on these eVTOLs as well. But we didn't know each other yet.

I think part of it is the European settlement structure. So if you look into a place like Sao Paulo or LA, you can imagine it could be a smart idea to take an eVTOL across the city. If you grew up here in Munich, you don't think it's a good idea to fly from the north of Munich to the south of Munich, because the city functions so well, it takes you like 35 minutes by car or by subway.

Well you've got good public transport here. You can't have that in the USA; public transport is for communists, you see.

I don't know what's the reason for it! But when we did our calculation, we said, 'well, if we did fly across town, we would spend five minutes in the cab, five minutes from the cab to the plane, five minutes flying across town, then another five minutes from the plane to the cab, and five minutes in the cab to my destination'. And I'm like, OK, this whole stack is super annoying, as a journey, because I'm always worried I'll miss the next one. And I didn't save a minute of time.

But on the other side, when we're traveling to neighboring cities here in Europe, that's where the pain starts, where it takes hours, and you're in traffic jams. And then you think like OK, if we could fly regional, it would be amazing, then we would save hours of trip time.

And that's how we then said, OK, we want to focus on regional eVTOL, and then took the decision for more capacity, because when you go regional, and you save one or two hours of time, then you can also start bundling people. Which doesn't work on very short trips – like, Uber tried this a lot in the US with Uber Pool. It never really took off. Because when trips are too short, people are not willing to wait 10 minutes for someone else to join. You just want to go. But if you save two hours, you're willing to wait. The longer the trip goes, the more you can bundle. That's what traditional airlines do all the time, bundle 200 people into a 2,000-mile flight.

Yeah, just to remind me, are you guys planning to launch your own service or manufacture and sell?

We had originally planned to launch a service and the production. We went away from that during the listing and said, we're going to partner with others to operate the airplane and launch the service. Because it's just too big of an investment step. Right now, part of our financing and the solution to the funding topic is that we're getting down payments from customers. You don't get down payments on an airplane ticket three years in advance! You get a down payment from an airline or from an executive customer who wants to buy an airplane.

And it's not just this, there's also the skill. For example, there are established players who operate in helicopters and airplanes every day. They know this inside out. They know the customers, they know the routes, they have the infrastructure. And we see right now that among the 640 pre-orders we have, many of them come from these existing operators who are looking for a replacement for the helicopters.

Our airplane basically does the mission of a helicopter, but you have a cabin of twice the size, you have much less noise and vibration, you are much safer from the redundancy. You have lower noise emissions to the community, and you're emission free. So they look at it saying we have everything but we need to fill that gap of this machine. And partnering with these guys is super valuable for us because they have all these ingredients already.

I notice you didn't mention that they should be heaps cheaper as well. Is that still the projection?

Absolutely, yeah, I think there's a number of reasons. The electric powertrain is cheaper in general than a gas turbine powertrain because you have way fewer parts, you have much less wear and tear, you don't have the safety issues of a helicopter where every single part is a single point of failure. You have all these mechanics and gearboxes, and if something fails, very often the helicopter comes down.

In eVTOLs, you have distributed propulsion, so you have redundant powertrains, and that reduces the criticality of all these parts. So, that reduces the cost, then the cost of energy is of course, much lower with flying with electricity.

And then also, the sheer economies of scale come into play. So, when you have lower noise emissions, better safety, no CO2, you have an overall more attractive product, which gets used more often, and your production numbers are going up. But on the other side, I would say, we also need to be cautious not to over-promise to the market.

There's people promising that you can fly like five times lower priced than helicopters today. That's very hard to achieve. Because if you look at the whole stack of costs, the pilot and landing fees and insurance and the airframe, these are all the same. It's still a composite airframe, it's still a highly skilled pilot. These things can change over time with autonomy, they can change with production, scale, etc. But we expect that initially, it will be a bit lower cost than a helicopter and then it will come down at some point to something closer to a high-speed rail ticket.

But I think one needs to be realistic about the timeframe over which this will happen. It can't be like a high-speed rail ticket on the first straightaway.

And to get there, you'll need to be manufacturing at more of an automotive type scale than a typical aerospace scale.

It won't be anything like automotive scale. If you look into the market forecasts, like scanning what is externally predicted by Morgan Stanley and others, and comparing that to our internal predictions where we usually want to be more conservative. You start to see that even with one aircraft, you can do an immense amount of passenger miles per year. So you don't need millions of eVTOLs to serve the world market – even in 20 years.

The number you'd need is a big number, much bigger than anything we've had so far in aerospace, but automotive is in the millions. eVTOLs is in the thousands, to tens of thousands. That's predicted, we're not there yet. We need to start humble, start small, make money with an existing market and grow from there. That's our strategy right now. Because everything else is predictions. But you have to get a real customer, giving you a real down payment.

You have to get a real ticket from EASA!

Exactly. And then, of course, we think we can, in the shuttle market, leverage the fact that we have more capacity on board and that will help us further reduce the price on the airplane.

The new batteries. Have you flown them yet?

No, we're torturing them on all the safety tests right now. We'll fly them in the conforming prototype.

And with that, our time's up and it's on to the next stop. Huge thanks to Meredith, Christine, Daniel and the Lilium team for putting together a visit for me. More to come on this visit shortly!

Source: Lilium