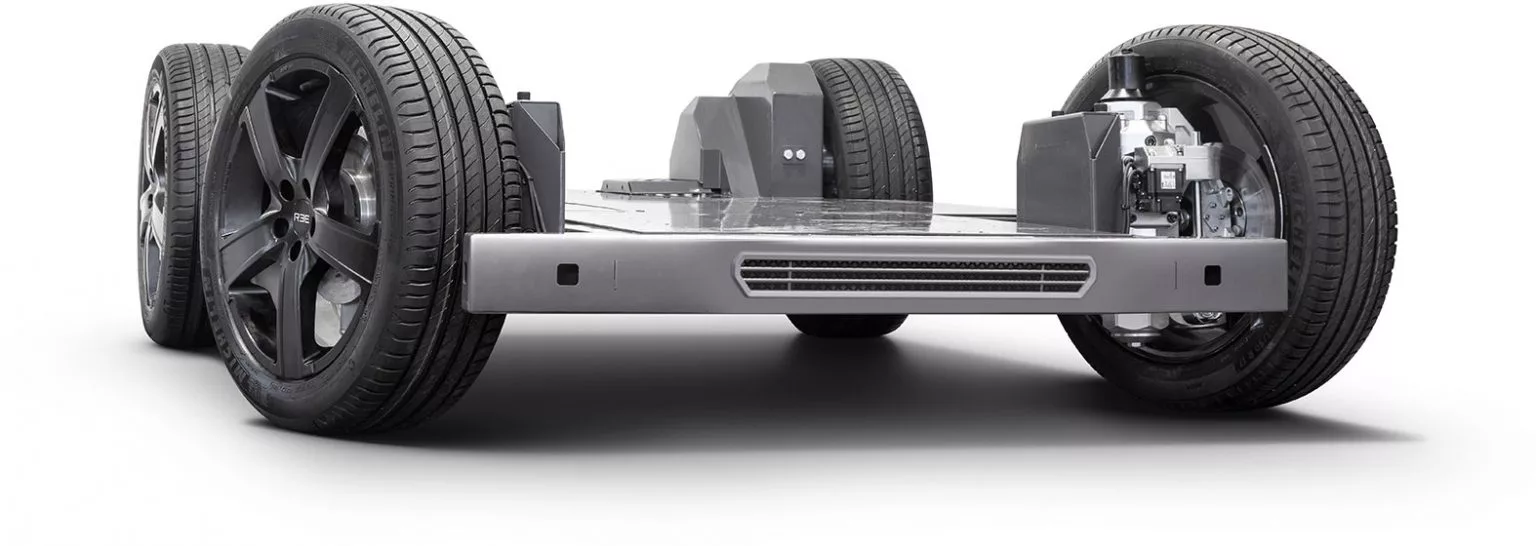

When we first encountered REE's ultra-modular EV chassis, we struggled to know what to make of it. Speaking to CEO Daniel Barel, we couldn't seem to pin down any specifics. What is it? A flat, modular vehicle chassis in which all steering, suspension, motor, gearbox and braking functions are bundled up into removable, replaceable "corner units" in the wheels.

These corner units have built-in electronics so that every single function can be fully electronically controlled. It's not just drive-by-wire, it's steer-by-wire, brake-by-wire, everything-by-wire. So you can put a steering wheel and pedals in if you want, but it's just as happy to take instructions from an autonomous drive system, or heck, even a remote control. There's no difference as far as the chassis is concerned.

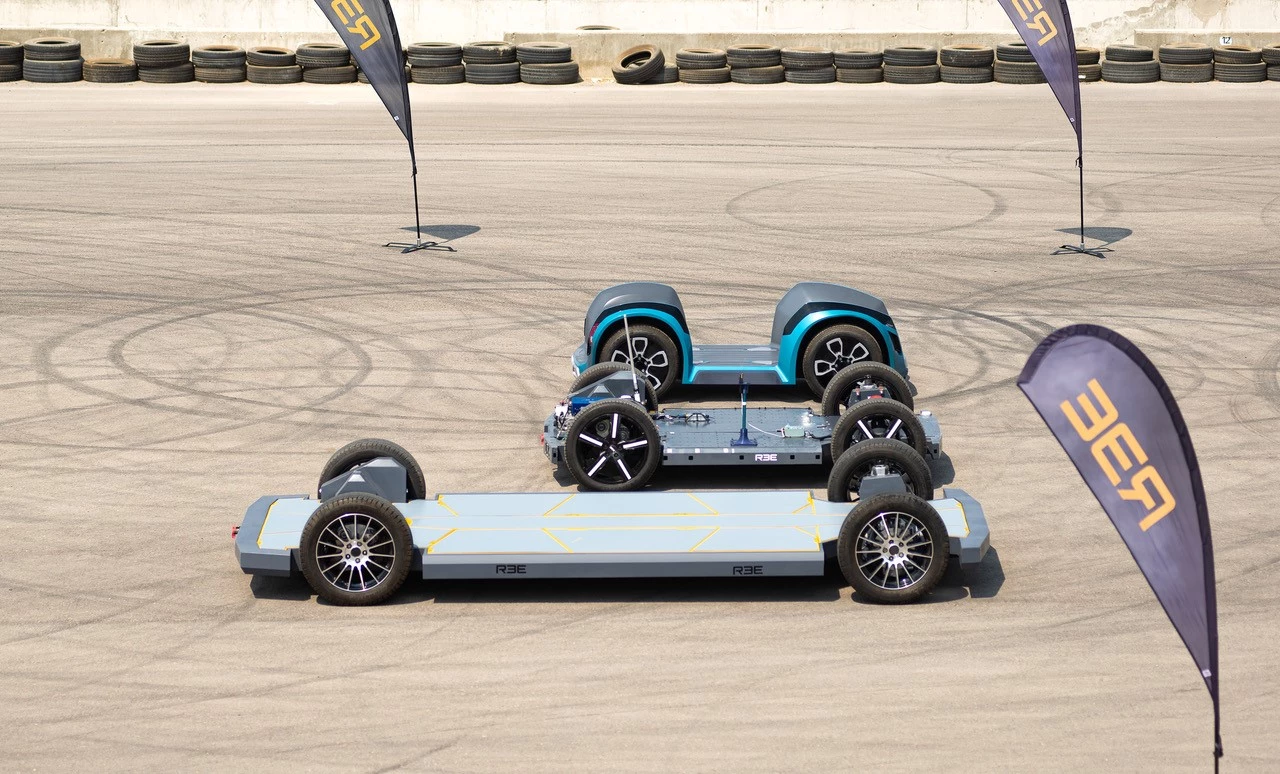

What could it be used for? Well, just about any kind of electric 4-wheeler. The big, flat battery pack offers a genuine "skateboard chassis" on top of which your vehicle design options are just about unlimited. There's no other chassis so flat, or that offers so much room for whatever kind of body you want to stick on top, be it a car, van, small truck, big truck, bus, automated delivery vehicle or crazy off-roader.

The corner units can be specified with a ridiculously wide range of options. Active suspension? No worries. 4 wheel steering? Piece of cake. How much ground clearance do you want? How much power? Desired torque? Top speed? Two or four wheel drive? Coming right up. REE can turn these things into just about anything, thanks to a network of relationships with tier-one component suppliers like KYB, Musashi, NSK, American Axle, Mitsubishi and others who are signed up to develop components specifically for these modules.

If anything goes wrong, mechanic's trips have never been quicker for a fleet operator. Yank the whole corner off with the release of a few bolts, stick a spare on, and the vehicle is back on the road lickety-split while the spanner team works out what the problem is.

It's a remarkably flexible and practical system, and some major automakers are buying in, seeing the wisdom behind working with a chassis that only needs to be crash-tested and approved once to be relevant for a broad range of vehicles.

Toyota has partnered with REE on its 'Flatformer' range of electric Hino vehicles, which will include everything from passenger shuttles and delivery vans to garbage trucks, food trucks and mobile medical services. More recently, Indian automaking colossus Mahindra signed an MoA with REE to develop and build an initial run of up to a quarter of a million commercial EVs.

Now, we've got some footage to look at, embedded below, showing three prototype platforms of varying sizes and specifications zipping around a racetrack and some obstacles. There's nothing on top of the chassis, bar the cameras and systems needed by the autonomous drive system that's in control, but the three prototypes are designed to represent different future use cases: a 1.3-ton last-mile delivery buggy, a 2.5-ton passenger and cargo transport, and a 4.5-ton delivery van designed for US market use.

It's not the most exciting thing ever filmed on a racetrack, for sure, and the rockin' soundtrack calls a certain degree of attention to that fact, but it does give us a good look at the hinged electronic steering and compact in-wheel suspension in action.

Perhaps some folk will need to see the bodywork, seats, paint and finish before they glimpse the massive potential of this monstrously flexible idea. Others will realize they're not looking at a car, van or truck that can be pinned down, they're looking at a radical upending and streamlining of the automotive design and production process that could hit the road with a thousand different faces, logos, body shapes and technical capabilities.

Source: REE